Choosing a frame for a greenhouse

Oftentimes, gardening grows from a hobby into a profitable business. In order to grow fruits and vegetables in cold spring conditions and not too long summer, it is necessary to equip a greenhouse on the site. It can be of any shape and size, made from a huge variety of materials, but any greenhouse is assembled, first of all, from a frame.

Peculiarities

The frame is a supporting structure on which a light-transmitting coating is attached: polycarbonate, film or glass. The choice of material for the frame should be approached responsibly, since a certain number of tasks are assigned to the frame. The frame, to which the translucent cover is attached, not only determines the shape of the greenhouse itself, but also maintains a certain temperature inside, while resisting the influence of weather conditions. And most importantly, the frame should be easy to assemble and made of lightweight material.

Materials (edit)

In order to determine the material of the frame, it is necessary to consider the main types of greenhouses, depending on the type of structure and the shape of the shelter. There are two main types of greenhouses - summer and winter. The latter differs from the first in a more robust structure, the presence of a foundation and a heating system. It is obvious that the construction of a small winter greenhouse in the country or near a private house will be much more expensive than installing even a fairly large summer greenhouse.

By the form of coverage, greenhouses can be divided into the following types:

- a gable "house" or a one-sided par-wall greenhouse;

- spherical, domed, or arched;

- trapezoidal;

- polygonal greenhouse of complex shape.

To determine the material of the frame, you also need to determine the material of the coating. One of the most common is plastic wrap. The cheapness of the material allows you to cover the greenhouse with a new film annually, maintaining the required temperature inside the structure. If additional components are present in the polyethylene, it is possible to improve heat retention and increase the penetration of sunlight.

For the construction of summer greenhouses, reinforced polyethylene film is in greatest demand.which is stronger than usual. With all its advantages, the film is a very fragile material with a short service life. It creates a "membrane" effect, due to which condensation accumulates on the inside and which prevents the free circulation of air in the greenhouse.

The second material option can be glass, which is the best for light transmission and has high thermal insulation. Fruits and vegetables are protected by glass from dew, rain and other precipitation. The disadvantages of glass are its high cost, fragility and a big devil, as a result of which difficulties arise when glazing a greenhouse.

Today cellular polycarbonate is replacing both cheap film and expensive glass, despite the fact that it itself is also a very expensive material. It is produced in the form of large sheets with a thickness of 4-32 mm. Polycarbonate has excellent light transmission, high thermal insulation performance and low weight. It is easy to bend and install without risk of breaking. However, it can deform with temperature changes. Polycarbonate eventually loses its high light transmission and must be completely replaced.

The least common materials for covering a greenhouse include spunbond and agrofiber.Such materials are created from polymer fibers and most of all resemble white and black fabric.

You can equip a warm garden on the site with your own hands or order the construction from professionals, but, in any case, three types of material can be used for the frame of all types of greenhouses: wood, plastic and metal.

Wood

Wood is the most popular material for building a greenhouse. Working with wood requires a minimum of tools and basic skills in working with them. It is the cheapest frame material with which all types of coverings can be used, however, it has several significant disadvantages.

Wood is more prone to decay processes than other materials., especially in contact with soil, so the wood base will last about 4 years. It is also impossible to equip a winter greenhouse from it. Treatment with antifungal agents does not help much, therefore, the wood of the frame can be placed in metal pipes to increase the service life. The second drawback is that the wooden beam does not bend, so it is impossible to make a rounded roof or greenhouse walls. When covering the rigid corners of such a frame with cellular polycarbonate, many small cracks are formed, which must be sealed.

Plastic

Most often, frames for greenhouses are made of PVC pipes, which bend well, easily stick together or are wrapped with ordinary tape. Plastic is a budget material with low thermal conductivity, its deformed part can be easily replaced with a new one without dismantling the entire frame. However, just like wood, it is not suitable for the construction of a winter greenhouse, because it quickly becomes cracked from low temperatures and is not attached to a concrete foundation. Plastic cannot be used in conjunction with a polycarbonate coating, since the latter is much tougher than the frame itself. In general, the construction of PVC pipes is very unreliable and can deform even by gusts of strong winds.

Metal

An iron frame is the best solution for creating a large winter greenhouse from available materials. Particular attention should be paid to the construction of the foundation, since metal frame structures are of significant weight. The most commonly used material is profile pipes, aluminum or zinc-plated profiles.

Aluminum profiles do not need to be painted, they are tough enough to use polycarbonate as a coating, but lightweight and last a very long time. Among the shortcomings, one can note the high cost of the material and the difficulty with self-installation. The purchase of ready-made kits for the construction of greenhouses limits the size and shape to those options that are presented on the market for construction services and materials. When assembling with your own hands, it also becomes difficult to buy a certain number of profiles that are sold in large wholesale.

Profiles for drywall are just galvanized and they can also be used to build a warm garden in the country or behind the house. They can be used to make rectangular and polygonal greenhouses, but it is impossible to build arched or spherical ones, since the galvanized profile practically does not bend. At a low price, they are quite durable, weigh little and serve for a long time. Most importantly, it is necessary to carefully cover such a frame, since the sharp joints of the profile can damage the thin film or carbonate.

It is easy to weld a frame for a large stationary winter greenhouse from a profile pipe. Durable pipes are easily attached to concrete, keep the shape of a bend and practically do not deteriorate over time. High thermal conductivity can be reduced by painting the metal with a light color and covering it with honeycomb polycarbonate. It is very important to have the skill of bending shaped pipes using special equipment or manually, so that the frame is sufficiently even and stable.In the absence of such skill, the frame can be all-welded and acquired already in finished form.

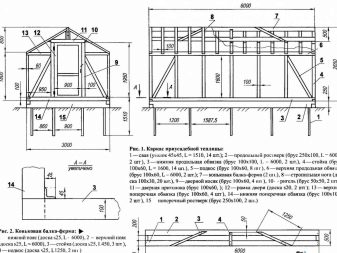

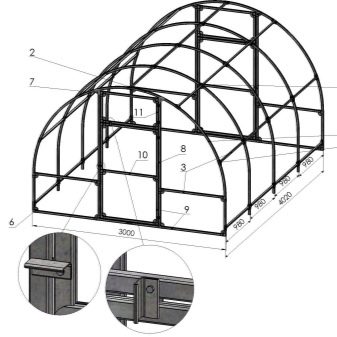

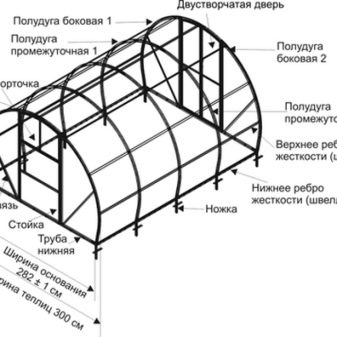

Drawings and diagrams

After choosing the design and material, the stage of drawing up the drawing begins. If you do not find special graph paper at hand, you can use ordinary notebook sheets in a cage, it is also quite convenient to place drawing elements on them. All constructions of the project should be carried out with a simple pencil, since it is easier to erase it in case of an error in the calculations. If you have design experience, you can also use a special drawing program such as Compass or Autodesk AutoCAD.

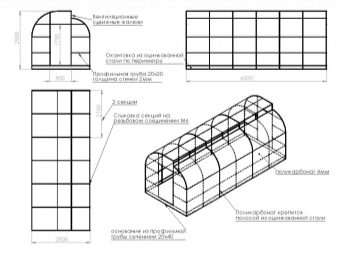

It is necessary to make a plan in at least two views - from the long side of the wall and from the end. Also, an excellent idea of the finished greenhouse will give its project in isometric view.

The design is carried out in stages.

- Determination of the scale. To do this, you need to take the planned dimensions of the greenhouse and translate them in a ratio so that the drawing fits on a small sheet. For example, when choosing a large square greenhouse with dimensions of 6x6 meters, you can draw a square with a side of 20 cm, then the scale of the drawing will be 1: 30.

- Drawing of the outer contours of a greenhouse with a given length, width and height.

- The foundation or base of the greenhouse is determined and applied, depending on the chosen design.

- Wall supports are drawn. In the case of designing a shed or gable roof, a rafter system is also drawn at this stage.

- Various horizontal elements and openings are added to the drawing - lintels, windows and doors.

- The final detailing is carried out and various notes are made on the finished structure, type of material and fasteners. For example, you can specify that for the construction of a greenhouse a profile with a thickness of 20x20 or 25x25 mm will be used, the coating will be polycarbonate, and the polycarbonate will be attached to the frame using a self-tapping screw with a washer.

Each type of greenhouse has its own design features. For example, the height of an arched greenhouse usually does not exceed the height of a bent polycarbonate sheet. Depending on its standard height, the roof of such a greenhouse will range from 1.9 to 2.1 meters. Since a curved frame is needed for an arched greenhouse, the bending radius will need to be calculated to build a drawing. This radius should not exceed the maximum permissible bending radius of polycarbonate sheets specified by the manufacturer.

For a greenhouse up to 3-4 meters long, only two arcs at the ends can be used as vertical supports. If the length of the greenhouse is more than 4 meters, it is necessary to add additional supports at a distance of 1-1.5 meters from each other. Such arcs are attached to the rectangular metal base of the greenhouse and horizontal rails between each other.

For a single or gable greenhouse, it is necessary to choose the correct angle of inclination of the roof - it should not be less than 20 degrees and not more than 45. It is advisable to use a strong steel profile for the frame, and add additional diagonal slopes to ensure strength between the vertical and horizontal elements. For the convenience of calculating the size of such a greenhouse, you can proceed from the length and width of a standard polycarbonate sheet. Then there will be no need to saw a material that is strong enough in width or length to cover an area of the required size.

Dome greenhouse (geo dome) is the most difficult type of greenhouse, but also the best in terms of illumination and resistance to strong wind and snow. Such a structure is created by connecting a large number of hexagons or triangles into a single system. It is easier, of course, to build a greenhouse with triangular elements. A stable geo-dome can be built of almost any size, but the most optimal is a diameter of 4 m and a height of about 2 meters.With such dimensions, you will need about 35 triangular elements with an edge length of 1.23 m and about 30 pieces with a length of 1.09 m. In order to calculate the exact amount, you can use a special calculator.

Installation subtleties

Before you start directly installing the frame with your own hands, you need to start preparing all materials and tools in advance. Purchase fasteners, a plumb line, metal scissors or a saw and a screwdriver at a hardware store.

After that, you can proceed to the construction process itself.

- The site is cleaned and leveled in the place where the installation of the frame is planned. It is also necessary to thoroughly clean the area of weeds and grass, since in greenhouse conditions they will grow and displace cultivated plants.

- The markings are made on the square and the foundation is equipped, if necessary. To erect it, you need to remove the top layer of turf and set up a double-circuit marking with pegs and a cord. Then a trench of the required size is dug, depending on the chosen greenhouse design and the frame material used. The finished trench is lined with a special membrane to protect it from moisture and filled with a mixture of cement, sand and gravel. To strengthen the foundation, you can additionally stick metal pegs around the perimeter of the trench or even assemble a separate frame from them.

- The assembly itself is carried out either directly on the prepared site, or not far from it, so that it is easier to transfer the finished skeleton to the desired location.

- We divide the timber or profile into pieces of the required length in accordance with the drawn drawing. The wood is sawn, the metal is cut with special scissors, the plastic is broken off or cut with a knife. When erecting an arched greenhouse, the profile is bent at the desired angle manually or using special equipment.

- First of all, the base is assembled. The wood is connected with self-tapping screws, the plastic is glued, and the metal can be welded with a special apparatus.

- Then the end parts are assembled immediately with the doorways and attached to the finished base.

- If necessary, additional vertical supports, horizontal and diagonal guides are assembled and attached.

- The finished frame is installed on the foundation or simply transferred and fixed in the intended place. After that, you can start covering or glazing the finished structure.

Before stretching the material, the frame can be painted or treated with various solutions against decay or corrosion.

Advice

When assembling an aluminum frame, it is better to buy perforated corners, this will greatly simplify the assembly and covering of the greenhouse. The design of a summer greenhouse can be made collapsible, then its service life will be significantly extended due to storage in a warm dry room throughout the autumn-winter period. If the greenhouse cannot be disassembled, then it is necessary to clean off the snow from it in a timely manner in order to eliminate the risk of deformation and breakage of the roof.

If the greenhouse is located far from the permanent place of residence, in a country house outside the city, the snow is not always removed in a timely manner. In this case, it is necessary to build a reinforced structure, which is selected depending on the weather conditions of the region. These greenhouses usually have a metal frame with a thickness of more than 1.2 mm. An additional thin arc welded from below to the main one can act as an amplifier for the arches of an arched greenhouse. In the upper part of the gable wooden greenhouse, additional transverse or longitudinal jumpers can be placed. And you can also reduce the distance between the vertical and horizontal elements of the frame, which will also reliably strengthen the structure.

The transparency of polycarbonate is influenced by the thickness of its sheet. Polycarbonate with a 4 mm sheet section will better transmit the sun's rays than polycarbonate with an 8 mm sheet section.However, the latter is much stronger and less prone to deformation when the surrounding air is heated and cooled.

The least common type of greenhouse is a recessed greenhouse. In this case, only its roof is above the surface, and the rest of the space is located underground. For the summer period, the roof of such a greenhouse is removed and seedlings are grown in it.

You can experiment with a non-standard shape or choice of material for a greenhouse, make it a small collapsible structure, or build a real glazed greenhouse. The main thing is, having studied all the advantages and disadvantages, to approach the choice carefully and be able to assemble such a greenhouse on your own.

For information on how to choose a frame for a greenhouse, see the next video.

The comment was sent successfully.