Infrared heaters for greenhouses: pros and cons

An infrared heater is a relatively young representative of climatic equipment. This useful device has become popular and in demand in record time. It is actively used for rapid local heating of premises for various purposes - apartments, private houses, offices, garages, car washes, construction sites. It is not surprising that infrared devices have attracted the attention of plant breeders with the possibility of using them to create optimal conditions for the life of green pets grown in greenhouses and greenhouse pavilions.

Peculiarities

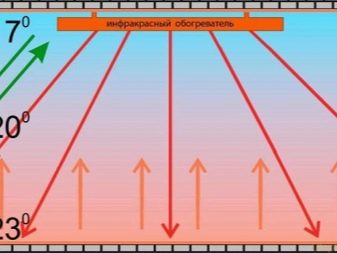

Our planet has its own heater - the Sun. Due to the unobstructed passage of the heat energy emitted by it through the air shell of the Earth, its surface is warmed, thereby supporting the life of all that exists. Infrared heating works on the same principle: by analogy with the sun's rays, infrared devices for greenhouses share their heat directly with the surrounding objects. A distinctive feature of infrared heaters is the flow of heat not into the air, but onto the ground. This heating method ensures optimal distribution of heat energy throughout the greenhouse pavilion.

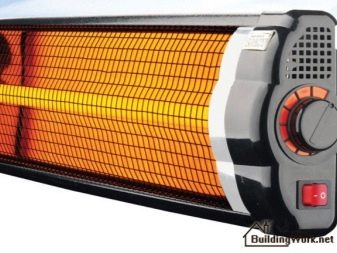

Despite its name, there is nothing complicated in the design of an infrared device. The outside is equipped with aluminum radiant panels protected by a heat-resistant coated steel casing. The filling consists of a heating element and a protective earth wire. The principle of operation of infrared equipment is also simple and straightforward: the heating element transfers heat to the plates emitting infrared waves. This energy is then absorbed by the surfaces of the surrounding objects and things that are in the radiation radius of the device.

Advantages and disadvantages

Greenhouse infrared heating has many benefits.

- Directionally heats and evenly heats a specific area of the room.

- Fast heating up time and heat spreading, which is felt already at the moment of switching on the device.

- Efficiency of heating provides a combination of high efficiency and low heat losses of devices. Electricity savings are about 35–70%.

- Works silently.

- Versatility of use - IR equipment can be used in any place, a variety of mounting methods.

- When heated, combustion of oxygen or the formation of a dust "storm" is excluded. In the process of work, the dust will circulate less in the inner space of the structure and settle on the landings.

- Since heating with an infrared device eliminates the problem of dry air or burning it out, a stable humidity will be maintained in the greenhouse - this is one of the integral components of a healthy microclimate for the full growth of plants.

- The heat prevents the development of molds and the formation of a favorable breeding ground for garden pests. Many of them are carriers of mosaic, late blight and other infections.

- The presence of temperature sensors provides several significant advantages. For example, one corner of the greenhouse can be occupied with heat-loving exotics, and the other with crops that need coolness.

- Climatic equipment is constantly being improved.The newest models have replaced the flat screen with a spherical one. In this case, the light streams have a larger scattering angle - 120 °, this contributes to an even distribution of heat, which is beneficial to the plants.

- Durability and trouble-free operation around the clock. The design of the heaters excludes moving parts, air filters and other elements that require periodic replacement or repair.

- The compact size of the devices, so they are hassle-free in transportation.

- Equipment fire safety.

- Possibility of self-assembly without the involvement of outside experts.

Infrared heaters for greenhouses also have some disadvantages.

- With the economical use of equipment, the organization of IR heating itself is quite expensive.

- The market is rife with reputable brand fakes. The gullible customer is still seduced by the attractive low price and promises that the device works "just as well" as the original.

- The need to accurately calculate the number of IR devices specifically for a particular room. At the same time, it is also important to determine which models are suitable for specific needs.

Views

When choosing an infrared heater, they are based on several criteria.

Energy source

The existing types of "infrared" can be:

- electric;

- gas (halogen);

- diesel.

Heating element type

Electric heaters are equipped with the following types of heating elements.

- Ceramic - have increased strength, heating for them is a matter of minutes, they cool down just as quickly;

- Heating elements - the advantages of tubular electric heaters are reliability and stable maintenance of the set temperature;

- Carbon - the design of such a heater is represented by vacuum tubes with carbon-hydrogen fiber filler.

The form

In appearance, heaters can be infrared lamps of various formats, foil panels or tapes. Compared to lamps, films or tapes provide the greatest energy savings and warms up the soil more evenly.

Mounting method

Before buying a "personal sun", you should immediately decide on the placement of the device.

Depending on the method of fastening, the equipment can be:

- mobile;

- stationary.

There are no questions regarding the first one - this is a portable technique that is moved to the desired place by means of wheels or special legs.

You can experiment as much as you like with the installation of stationary models, since they are available in several types:

- ceiling;

- wall;

- plinth;

- suspended.

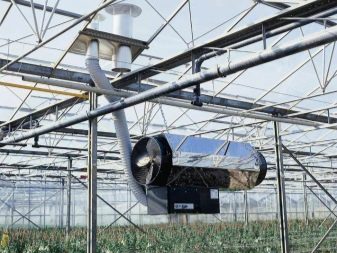

Suspended models differ from ceiling-mounted models. Suspended heaters are built into a suspended ceiling structure, which is pre-designed for the placement of devices. To fix the suspension devices, use special brackets and anchor bolts with a pitch of 5 to 7 cm.

The optimal place for skirting heaters is under the window, which helps to realize their full potential by blocking cold and drafts from outside.

Heating temperature

IR equipment differs in the degree of heating of the device itself.

Devices can be:

- low temperature - up to 600 ° C;

- medium temperature - from 600 to 1000 ° C;

- high temperature - over 1000 ° C.

Medium to high temperature appliances are good in spacious and high greenhouse pavilions. In these cases, warm air can be guaranteed to reach the ground, and not just circulate in the middle.

Radiation range

In accordance with this parameter, IR equipment is:

- long-wave;

- medium wave;

- shortwave.

According to Wien's law, there is a direct relationship between the wavelength and the temperature of the surface on which the radiation hits.Under high-temperature radiation, the wavelength increases, but at the same time they become harsh and dangerous.

Lighting devices in the form of lamps with a maximum incandescence temperature of 600 ° C are good for heating large production greenhouses. Long wavelength equipment eliminates strong heating. It is usually used in small greenhouses at their summer cottage.

IR heaters have additional options.

- In many models of infrared equipment, a thermostat (thermostat) is provided, which is responsible for maintaining the set temperature.

- Any thermal heater must be equipped with a thermal switch that reacts to overloads and automatically turns off the device, preventing it from overheating.

- To ensure all-round safety, infrared technology is also equipped with insulators that prevent the housing from contacting with the heating element.

- Especially advanced models have a light indication that informs the user about the problem that has arisen, so that he can quickly navigate and take measures to eliminate it.

- The spontaneous shutdown of floor models occurs when overturning, which simultaneously prevents breakdown and reduces the risk of ignition to zero.

- The Antifrost system is designed to protect the heater from ice formation. Even if the heater is used in the harsh Russian winters, you do not need to worry about the performance of the infrared equipment.

- Many models of infrared heaters have a timer, which makes operation much more comfortable. Thanks to the ability to set the desired on and off times, you can reduce fuel costs.

How to place?

For the correct placement of heaters in the greenhouse, it is necessary to proceed from the performance of the equipment and the range of dispersion of infrared rays.

The organization of uniform heating with infrared devices implies the observance of several conditions.

- There must be a distance of at least one meter between the heater and the landings. When germinating seedlings, the IR lamp is raised to a designated height, preferably by means of a ceiling mount.

- As the seedlings grow, the distance is increased by moving the lamp up. You can simplify the task by using less powerful lightweight structures on suspensions.

- With a greater distance from the heater to the ground, the ground is cooler, but the device can heat a large area with plantings.

Therefore, when planning plantings, you need to be guided by the needs of the plants, and only then think about how to save energy.

- In the greenhouse, heaters must be installed at least half a meter later. If the area of the greenhouse pavilion is 6 m, then a couple of devices should be enough. In a large greenhouse, it is most reasonable to arrange the heaters in a checkerboard pattern to prevent the formation of inaccessible areas for heating.

- Heater color. Heating of greenhouse pavilions in winter with gas infrared heaters of the ceiling type showed the following. With light radiators, where the bulb heats up more than 600 ° C, it is most practical to heat large rooms, using devices as the main sources of heating. With dark radiators, it is optimal to heat winter greenhouses.

Advice

To find out which equipment is better, you should familiarize yourself with the conditional classification of this type of climatic technology.

- Scope of application. Installations are for industrial purposes and for household needs. The latter are used to heat small-sized structures. Although some summer residents practice the use of factory units in their personal plots. Most of these devices emit short waves, contributing to the enhanced development and growth of plantations, but negatively affects human well-being.

- Fuel. In cases of greenhouse business, the purchase of electric emitters is an unprofitable investment, since the energy consumption is too high. A rational solution is heating large pavilions with gas infrared equipment.

- Fixation method. IR equipment, which is used to heat industrial greenhouses, is mounted to the ceiling, and for household models, tripods are provided or fixed to the walls.

- Productive capacity. Before purchasing installations, you need to decide on the required amount of infrared technology. One industrial installation is capable of heating a maximum of 100 m². Household infrared panels with a relatively low power can heat the ground up to 20 m².

Reviews

An analysis of the reviews of the owners of infrared heaters showed that most of them do not regret their purchase.

Benefits include:

- reasonable price;

- energy savings;

- heating rate;

- thermal effect;

- silent work;

- do not dry the air;

- increased growth of seedlings next to the device;

- compactness and mobility.

Some users blame themselves for refusing to equip the device with a thermostat, which the seller strongly advised to do. If we talk about the cons, then you should pay attention to the cost of products. The latest innovations are available at a high price, but they come with a lot of additional options.

For information on how to additionally heat the greenhouse, see the next video.

The comment was sent successfully.