How to make a TV bracket with your own hands?

After purchasing a new TV, a large number of people have problems with its compact and comfortable layout for viewing. Since there is often not enough space in the room for which this household appliance was purchased, it becomes relevant to mount a TV on the wall using specialized brackets (holders). Such holders will make it possible to securely fix the TV receiver on the wall, thus gaining space in the room. What are such clamps, how to make them on your own, we will consider in this publication.

Features and requirements

In the bulk of the produced television equipment, mounting is practiced according to the standardized VESA system. A variety of installation modules are available based on standard hole spacing (in millimeters). As a rule, these are 4 fixing points, which are located on the back cover. "Quadruple" VESA scheme is realized in the form of a square or a somewhat elongated rectangle. In the fixation points, standard mounting bolts may already be provided.

If they are not there, then they are in an individual container or with other elements.

It is impossible to fix a television receiver, which is especially important for expensive branded samples, on non-standard fasteners. As a result, the bolt heads are often designed for special tools, and the holes are filled with plastic. In such situations, a certified technician should mount the TV to an industrial-grade holder. Without marking it in the form of the guarantee coupon about the measures taken, the guarantee obligations are canceled.

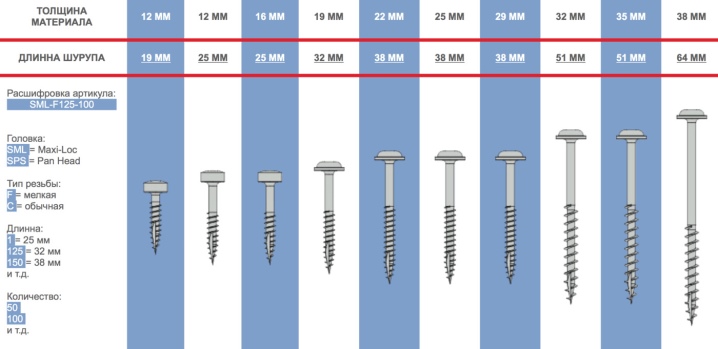

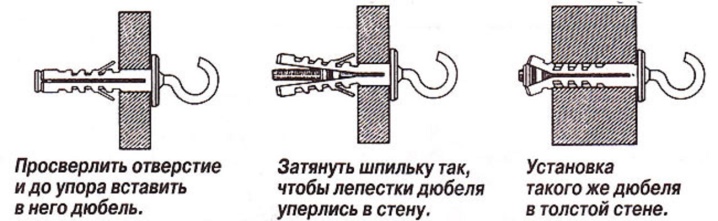

When mounting standard dowel holders on main walls, it is advisable to select steel dowels, in extreme cases from propylene. For walls made of cinder blocks, foam concrete - exclusively polypropylene. Self-tapping screws with a diameter of 4 mm or more, or the same as the first number of the screen size diagonally (in inches). The immersion of the self-tapping screw into the main wall without a layer of finishing material should be equal to:

- for concrete walls - 10 mm + diagonal size in centimeters;

- for brick walls - 30 mm + diagonal size;

- for foam concrete walls - 50 mm + diagonal size.

The above requirements have nothing to do with plasterboard walls, since they do not have a good load-bearing capacity. When the drywall is adjacent to the main wall, the installation is carried out directly on the wall. In this situation, holes of the correct diameter are drilled in the drywall for the diameter of the dowel head.

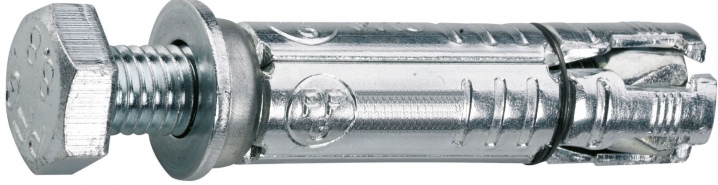

An extension is made of a metal bar on the dowel, and a hexagonal socket wrench with a hammer puts it in place.

If the plasterboard sheets are fixed on the frame, and the cladding layer is less than 12 millimeters, then you will need to find another place or install the TV receiver on a stand. The only valid option is to have information about the location of the support structure, which can be used to hang the holder.

What do you need?

Before starting the assembly and installation, you need to correctly sort all the tasks in order of importance, then select the appropriate material. First of all, this will depend on a number of key components:

- the amount you are counting on;

- structural reliability;

- the mass of the television receiver;

- fastening method;

- the material from which the walls are made.

Important: you should not profit from the used material and fasteners. The service life of the equipment will depend on them.

There are a sufficient number of ways to assemble the holder. The choice directly depends solely on your imagination. If you want, you can design an original design, decorating the style of the room, even with this insignificant element.

The basic options will require you to provide tools and materials, which are preferable to stock up in advance.

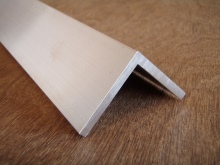

- Metal corners. To do this, you can use ordinary plates bent at an angle of 90 degrees.

- Bracket holder handle. It can be made movable for unhindered position changes. It should also be made of strong metal that can withstand the load from the TV.

- Wooden slab from a solid board or laminated chipboard, fiberboard, chipboard panels. It is used for the most reliable fixing of the TV case to the mount.

- Specialized clamps to the wall.

- Self-tapping screws, bolts, dowels.

- Electric drill.

- Perforator.

- Drills for wood and iron.

Important: if necessary, you can use auxiliary materials provided for a specific sample of the product. We only give a standard kit.

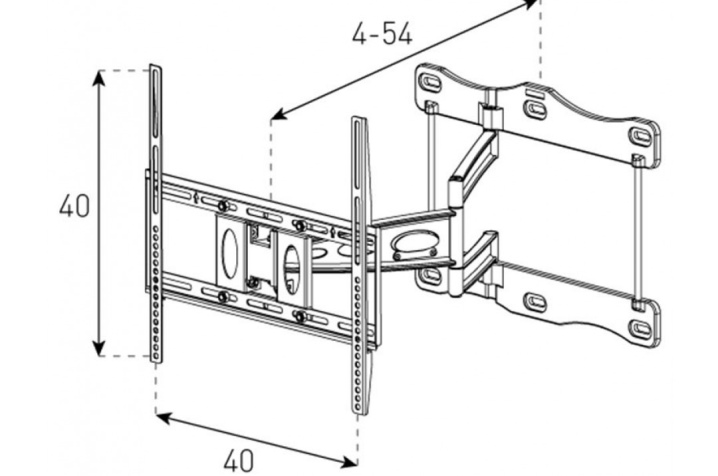

In addition, it is necessary to calculate the dimensions of the location area and the proposed structure. In the option when there will be a movable mount, you should also consider the space for its unhindered movement. To make the assembly easier, it is recommended to build a drawing with exact parameters for yourself on paper, so that you can then navigate by it.

Manufacturing steps

Some manufacturers entrust the installation of holders to fix the TV receiver to any craftsman. In this regard, the consumer has the freedom to choose methods. High-quality tool holders are expensive, but DIY tool holders can easily be made by hand.

The technology for creating corners depends on the preferred design: it will be a stationary or mobile version.

Stationary design

This is the most common and undemanding way. Such fasteners can be made of both wood and metal.

Fastening made of wood

In order to make fasteners out of wood, several parts are required.

- Wooden slats (at least 2 pieces). They must be made of hardwood. The length of the wooden slats is about 10-15 centimeters longer than the back cover of the television receiver. To communicate the slope, the top rail is made slightly thicker than the bottom.

- Self-tapping screws with rings (for wood).

- Hooks and propylene dowels.

The anchorage is constructed by following a series of steps.

- 2 self-tapping screws are screwed into the upper edges of each of the wooden slats, on which the rings are fixed.

- After that, these rails are mounted on the back cover of the television receiver.... For this, there are specialized mounting holes on its body. A wooden rail with a thickened side is mounted to the top of the TV. The second is mounted to the bottom of the receiver.

- Following this, the spacing between the rings horizontally and vertically is measured., and the mounting points of the hooks are marked on the wall.

- Holes are drilled at the marked points in the wall and dowels with hooks are laid. After their installation, the television receiver is suspended by means of rings located on the rails.

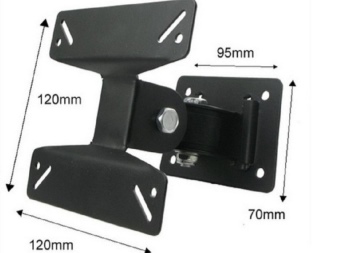

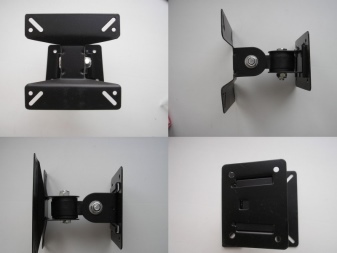

Metal bracket

To create a metal holder, you need the following materials:

- corners made of aluminum (4 pieces);

- one spoke from a bicycle wheel with a diameter of 2 millimeters;

- fasteners (dowels, screws, bolts).

The size of the corners, the types and sizes of hardware are determined based on the characteristics of the TV.

Two corners, as in the above-described version, are fixed to the back of the television receiver, the other 2 - to the wall by means of dowels. At the corners, holes are drilled for the dowels and, additionally, in their upper area - for the knitting needle.

After that, the corners fixed on the TV are connected to those located on the wall in such a way that the former enter the cavity of the latter.

In order for the television receiver to be held vertically, a spoke is inserted into the corner holes located at the top. For heavy samples, it can be replaced with steel.

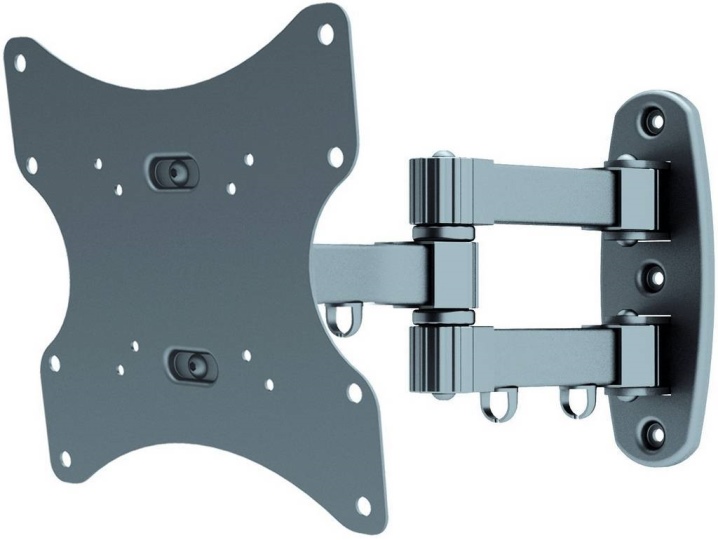

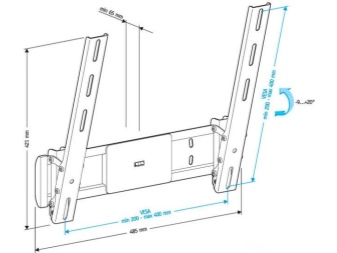

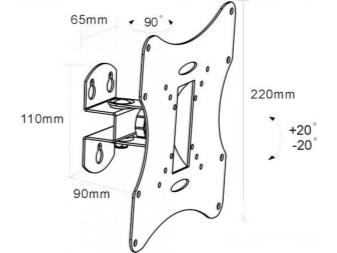

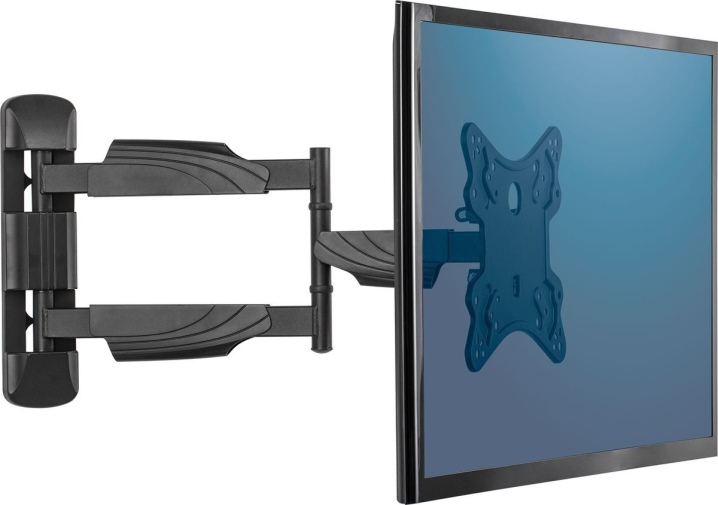

Swivel bracket

Movable holders provide wide freedom of action: turning the TV receiver in the required direction, bringing it closer. Certain types of structures correct the vertical tilt of the television receiver, which may be necessary when the television receiver is suspended high. As a result, the movable wall-mounted TV holder allows comfortable viewing from any area of the room.

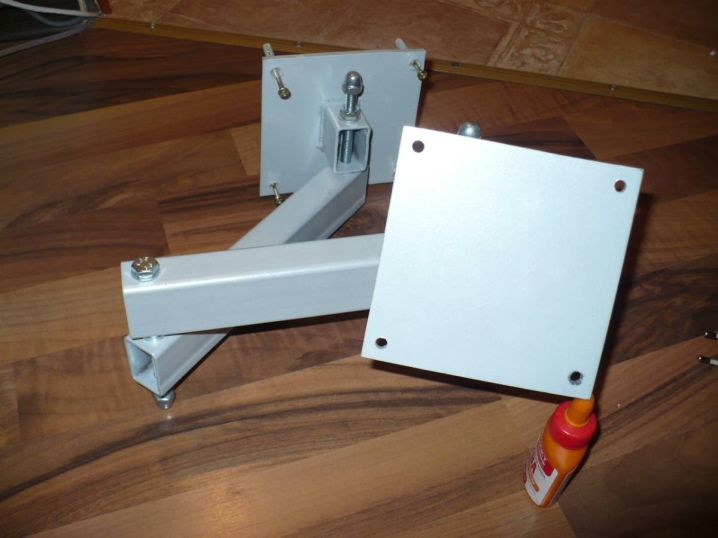

There is essentially no way to create a fully functional movable holder in a home environment, but to make an imitation of it is real. You need to prepare the following materials and tools:

- square iron tube (square profile) with a cross section of 20 × 20 millimeters;

- 4 x 25 mm corners;

- 2 iron square slabs 200 × 200 millimeters;

- bolts;

- washers and nuts;

- dowels;

- hacksaw with a blade for metal;

- electric drill;

- set of drills for metal;

- brush or spray bottle;

- black paint for painting metal structures.

Consider the sequence of work.

- Take an iron plate and make 4 dowel holes in the corners.

- On the other plate, make holes that match the holes on the back of the TV receiver.

- Cut the square profile into 3 pieces. The first is for wall fixing of the holder, the second is for connecting the elements and the third is for fixing the TV receiver. The size of the pieces depends on your preferred holder design.

- Paint all created elements with paint.

- After the paint has dried in the middle of the fixing plates, screw 2 corners each with bolts. The distance between the corners should allow the square profile to move freely. Note that the corners should be horizontal on the wall mount and vertical on the TV holder.

- Fix the pieces of a square profile between the corners with bolts, first drilling holes in them with an electric drill, placing washers between the tube and the corners.

- Place the central piece of the tube at the bottom between the pipes of the fasteners and tie them with long bolts.

- Fix the plates with the strapped square profile to the wall using dowels and bolts, then attach the holder to the TV receiver.

- Adjust the angle of inclination and tighten the nuts.

In a similar way, we can make any kind of holder ourselves. At the same time, no specific knowledge is needed, and the investment is minimal.

Having shown imagination, you can modernize the device, making it more remarkable, extraordinary. Paint in a color that is in optimal harmony with the interior decoration of the room. At the end of the event, you can watch your favorite TV programs and movies in comfort.

Recommendations

First of all, make sure that the manufacturer agrees to have his products hung on the wall. All you need to do is flip through the instructions for use. There are such modifications of plasma devices for which operation in a suspended position is contraindicated, but there are also direct weight restrictions.Among other things, the very place and conditions in which the plasma will function is important.

When choosing the location of the TV, take into account that the equipment must be ventilated.

In a different scenario, the possibility of premature failure of hardware devices increases.

Often flat TV receivers are installed too tightly to the plane or they are mounted in wall niches. This is allowed, but very carefully. Everything is explained by the fact that for the normal functioning of an LCD or plasma device, free space and air are required for ventilation. Otherwise, it will simply overheat, which threatens an early breakdown of the device.

If this factor is important for you, then make a niche that will be larger in size than a television receiver. In this case, in the depths of the niche, air will circulate, cooling the hardware units of the equipment. Make sure that the TV does not overheat, as this is a particularly common failure factor.

Flat panel television manufacturers are unanimous about some limitations.

- TV Receiver cannot be suspended in a confined space. It is required to provide it with the circulation of air masses and cooling in accordance with the passport data.

- When its mass is over 25 kilograms, then hanging it yourself is highly discouraged.

- A specialist should not doubt his own abilities, in other words - flawlessly own an electric drill and the ability to drill concrete.

- Cable connections are fixed exclusively after the TV is placed on the support.

- If it is mobile, then you need to make sure that that the cables will not have risky tension, and will be connected freely without the threat of a short circuit.

This is what the manufacturer recommends.

But by and large, it is already clear that it is required to fix reliably, and the mount must withstand a more decent load than the technical equipment that we intend to install.

Expert recommendations that will make it possible to quickly choose a suitable place for mounting your TV.

- It is forbidden to place the TV set on the wall in which the communication lines pass. First, establish where exactly the wiring is hidden so as not to damage the electrical cable during the installation of equipment. For this purpose, specialized tools are practiced: metal detectors, indicators and detectors.

- The corner of the wall is not always the most appropriate place for a TV device. Very tight spaces increase the risk of mechanical damage to complex machinery. Likewise, installation between shelves is prohibited.

- Install the equipment on a solid wall that does not decompose or crumble. Otherwise, the screwed-in self-tapping screw can fall out after a short period of time.

- The TV receiver should be located as close to an electrical outlet as possible. In this case, you have the opportunity to hide the wires without any problems.

In conclusion, it should be noted that even homemade holders with all possible bells and whistles will not replace factory designs in terms of reliability and quality.

How to make a TV bracket with your own hands, see below.

The comment was sent successfully.