Features of hemp material

Quite an interesting question, what is hemp, and from what plant the material is made. On the basis of hemp, natural fiber cords and many other products are obtained. It also has a long and glorious backstory that should be kept in mind as well. It is necessary to take into account the color of the threads and the properties of the fabrics from the stems, as well as know who produces good hemp and products from it. All this is discussed in the article.

What is it and what is it made of?

In a world where new materials appear almost every year, you should not forget the old options anyway. One of the good examples, undeservedly pushed aside products, is just hemp. This is a rather coarse natural fiber, which was extremely popular several decades ago. It should be noted that in the past our country occupied for centuries, up to the middle of the twentieth century, one of the leading places in hemp production. But this will be discussed a little further.

An important question - if the hemp is made from a plant, then from which one. And the answer is quite simple - hemp is used for its production.

But you should not be afraid: a special type of hemp mass is used - it is produced from "technical" varieties that do not contain narcotic and other toxic components. Such plants are grown strictly for industrial purposes, and special oil and some other products are also obtained from them.

Hemp is obtained by processing stems that are similar in structure and appearance to flax stems. Bast tufts are concentrated mainly in the upper part of the shoot. There are also below, but there are noticeably fewer of them. But it is worth noting that there was another type of plant from which hemp was produced. We are talking about Manila hemp, which is produced from various members of the banana plant family.

This product has alternative definitions:

- abacus;

- baked coconut;

- muse;

- manila fiber.

The quality of Manila hemp depends on its composition, or rather, on which part of the leaf the raw material is taken from. The best quality is the product obtained on the basis of the lateral part of the inner side. Outside, the fibers are much worse. But it still makes sense to speak first of all not about such "exoticism", but about a product more familiar to Russia. The color of the hemp, if we are talking specifically about organic matter and residues, and not about a product that has been bleached and processed in some other way, may be:

- silvery-gray-greenish (these are the best sails);

- yellowish (such a canvas is a little worse, but also highly appreciated);

- dark (of various shades) - this is already the least quality product.

The old technology of hemp production deserves to be described in more detail. After mowing the hemp, they knitted it into sheaves. In reservoirs, these sheaves were soaked for several months in a row, pressing down with a load. In some cases, it was possible to soak raw materials in a matter of weeks, but this was an exception to the rule. The process eliminated the loss of lignin, which guarantees increased strength and resistance to decay.

The moment of readiness was determined by the degree of softening of the raw material. As soon as it became soft enough, the sheaves were removed from the water and dried right on the shore. The next step was beating, which helped to remove the husk.

The threshing process involved the use of a crush, that is, a pair of boards with a stick placed between them. The mass was rolled up in small portions to facilitate the work.

The hemp has to be crumpled until only pure fibers remain. Should not be among them:

- chopsticks;

- inclusions of husks;

- unnecessary impurities.

The next step is to run the comb until the hemp fiber appears. You can twist and spin from it.

The base of the fabric was prepared on a so-called warp frame. Then this base, wound on a drum, was woven on a hand loom. But this did not end there either - the hemp of a homemade sample had to be bleached and lightened, and at the end of everything - washed with the help of:

- liquor obtained from wormwood ash;

- white clay;

- the so-called "soapy grass".

Short story

Traditionally, hemp is made from hemp. One of the traditional Russian varieties of it (southern) was cultivated in the North Caucasus and even reached the Kuban. But there was even more Central Russian technical hemp, which was grown in:

- Orel;

- Bryansk;

- Penza;

- Mordovia;

- EAO.

There was not much difference between the varieties. It only touched the thickness of the stems. In the southern variety, they were twice as thick.

Before the era of mass production, large cannabis stalks had to be soaked in running water for a very long time. Then home-made machines were used that could separate the fiber and the middle of the stem.

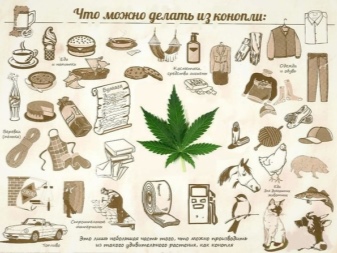

The fibers also had to be processed with specific compositions that imparted certain qualities. On the basis of hemp were created:

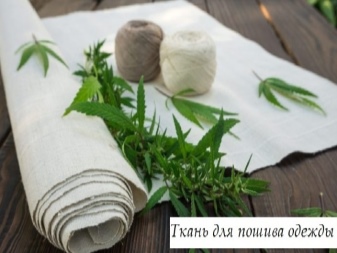

- various fabrics;

- fishing nets;

- coachman's reins;

- tow for caulking;

- sailcloth for river and sea vessels;

- ropes and ropes for sailing ships.

The reasons for the active use of hemp in the sailing fleet are quite obvious. They appreciated that it was the only natural woven material that did not weaken in contact with sea water.

Even today, when there are nylon and other options, hemp sails and ropes still retain their relevance. Of course, from a certain point, the artisanal processing of hemp ceased to satisfy all the growing needs of consumers. And therefore, whole factories appeared that were engaged in its production.

These enterprises worked very actively until the middle of the twentieth century. They made paper, fabrics and other products from hemp. The stems were soaked, of course, not in rivers already, but in large reservoirs. Then they were ruffled in a special workshop, where fibers up to 0.7 m in length were separated. The separated threads were carefully dried, cleaned and ruffled again, getting threads from 0.175 to 0.25 m in length.

But here it is worth returning to the "origins". Hemp began to be cultivated about 2500 years ago. Even then, farmers and artisans in Eastern Europe appreciated it. It is known that the Slavic tribes were very active in cannabis breeding. It is believed that hemp was grown for the first time in Asia Minor and India, most likely at the same time. Archaeologists find hemp seeds in layers over 3,000 years old.

They were found both in Siberia and in Egypt, which convincingly shows the importance of hemp production already in ancient times. Then, on the basis of these fibers, we obtained:

- ropes;

- sail;

- clothes.

By the early twentieth century, more hemp was produced in Russia than anywhere else in Europe. Italian and Austrian factories produced 20% of Russian output each. Serbian, Japanese and French enterprises were also noticeable on the market. Together they made no more than 5% of the volume that was produced in Russia. And even earlier, in the 18th century, domestic hemp was even more important - it was used extremely widely in the navies of different countries, including Britain.

The scale of production at that time was, accordingly, simply grandiose. In the same 18th century, up to 90% of all paper on Earth was of hemp origin. Cannabis breeding in our country retained continuous world leadership even in the 1950s. The quality of the hemp fiber has been highly appreciated by experts all over the planet.It was not even the appearance of new materials that dealt a crushing blow to the scale of its production, but the 1961 Convention on Psychotropic Substances.

But it is quite obvious that the struggle was, first of all, not against the drug mafia, but against a successful competitor, who could not be knocked out using the usual methods.

What factories do they produce?

Hemp production in Russia is carried out by:

- in the North Caucasus;

- on the Volga;

- in the West Siberian regions;

- in the Oryol, Bryansk, Penza regions;

- in the Nizhny Novgorod and Kursk regions;

- in Mordovia.

Mordovian factories are enterprises:

- Temnikovskoe;

- Krasnoslobodskoe;

- Sabaevskoe;

- Chamzinskoe;

- Staroshaigovskoe;

- Kochkurovskoe;

- Atyashevskoe;

- Insarskoe;

- Dubenskoe.

Also, the release of hemp is occupied by:

- Khomutovsky and Mikhailovsky, Dmitrievsky and Fatezhsky plants (Kursk region);

- JSC "Kubanpenvolokno";

- Kuraga and Idrinsky enterprises;

- Trubchevskaya factory;

- Toguchinskiy hemp plant (Novosibirsk region).

Speaking about the production of hemp in other countries, it is worth noting this state of affairs:

- PRC - fully self-sufficient in products and actively exporting goods, in addition, there is an official confirmation that statistics do not take into account all production;

- Canada, France - a similar position;

- South Korea - strong limitation of the size of cultivated areas, partial dependence on imports.

But it is worth noting that Canadian production is focused primarily on obtaining seeds. The hemp grown there has no industrial value.

It can be assumed that the situation will gradually improve, and the restoration (after the ban was lifted in 1998) will be completed in the next 20-25 years. But in the countries of the European Union, the areas occupied by hemp are already growing significantly.

Experts note that abroad, the EU and the PRC are in more or less the same positions in terms of the level of development of cannabis breeding. The same applies to the turnover of finished processed products. In other regions of the world, the potential demand is much higher than the current level of production. A strong obstacle in this regard is the prohibitive laws of the United States and other countries.

Among the individual enterprises, the most engaged in the production of hemp are:

- HMI Group;

- Hemp Flax;

- Natural Oil end Fibers Ltd.

Applications

Do not think that today hemp is used only for the manufacture of sails and ropes. This material has high strength. According to some reports, in the past, armor was even made of it, which perfectly resisted the blows of sabers and swords. Whether this is so or not, it is impossible to say for sure, but nevertheless, decent mechanical qualities are undeniable. Important: the very first "historical" Levi, s jeans were made from hemp, because it is quite safe and comfortable.

The environmental friendliness of hemp yarn is also appreciated in many other areas. Nowadays, the same ropes, ropes for sailing and other ships, boats must be as safe as possible for the environment. And traditional natural material significantly outperforms nylon.

It is also supported by:

- zero risk of electrification;

- resistance to heating and ultraviolet light;

- tensile strength.

Hemp cords and ropes, like their jute counterparts, are often used as seals in wooden houses. They are also used for decorative finishing of houses, but much less often. A resinous strand of hemp fiber is used as a packing gasket in pipelines. It is wound on the joints.

They can also take an untreated strand for this purpose, but it is worse from a technical point of view.

Hemp fabric may well be used in clothing even in the 21st century. And its prospects, due to the growing popularity of ecology, will only increase. Modern hemp jeans and shirts are made using a completely new technological process developed in the 1980s.It allows you to remove lignin without losing strength, thereby eliminating excessive coarseness. The result is an even more pleasant and comfortable fiber than cotton denim loved by many people, it is able to maintain an optimal microclimate.

But hemp fiber can also be used to make washcloths! It is a durable and completely hygienic device for one of the most important daily routines. Burlap is also made on the basis of hemp. And if for clothes the rigidity and even roughness of the raw fabric is a minus, then for the bag it is rather a plus, since this quality increases the service life and reliability. But hemp (hemp) paper deserves a separate analysis.

As already mentioned, it was very widespread for several centuries. And only the growing demand for paper forced to pay much more attention to forest trees. However, now the situation is changing again, and obtaining paper from hemp is more and more relevant. Good hemp varieties grow as fast as fast-growing wood, and even outstrip it. Moreover, such a culture is resistant to pests and requires only the most minimal care.

Hemp can also be used:

- to get twine;

- in the production of fiber-cement boards;

- for the production of high quality tarpaulins, fire hoses, bed linen and other textiles.

The comment was sent successfully.