All About LED Self Adhesive Tapes

LED strips as a light source are ahead of their predecessors in key parameters - efficiency, moisture and dust resistance, reliability (they cannot be accidentally broken). They have long supplanted spiral and fluorescent lamps for a long time.

What it is?

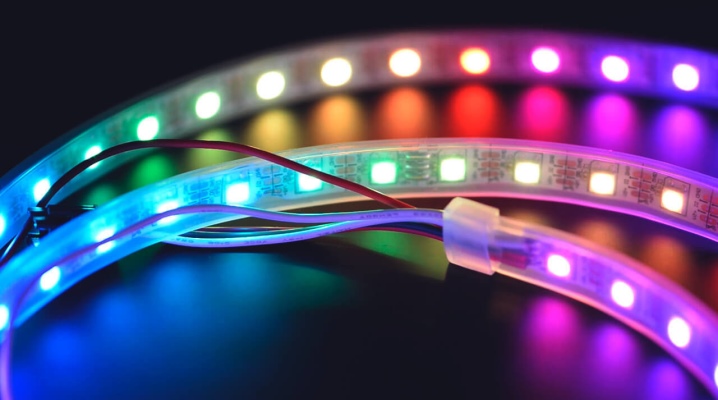

Light-emitting diode (LED) self-adhesive tape is a replacement for simple LEDs, which are usually placed on a printed circuit board. It does not need element-by-element installation - it is installed quickly and easily, and the wires are soldered only at the very beginning. White glow ribbons are common along with colored (monochrome) ribbons. The most popular colors are red, yellow, green and blue.

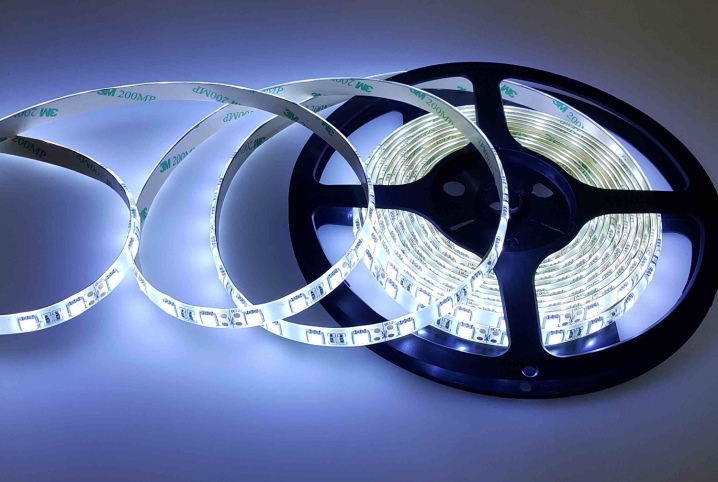

LED strip is a flexible substrate with LEDs soldered onto it. The buses ("plus" and "minus" for power supply) are reliably isolated from each other - a short circuit is completely excluded here. For partial protection against voltage surges on the strip, ballast current limiting resistors are soldered at regular intervals. A composite rubberized substrate acts as a dielectric, the reverse side of which has an adhesive layer and a protective film that does not allow it to dry out during storage.

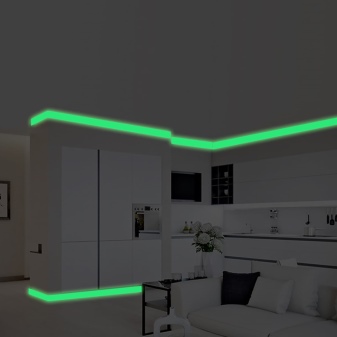

The flexibility of the tape allows this light source to be adhered to any surface with any relief.

The main principle of building such light sources is a series connection of LEDs. This is possible due to the presence of special contacts on the busbars, isolated at all other points of their running. On low-voltage tapes, these LEDs are connected in parallel, on high-voltage tapes - in series. The tape can be cut into fragments - due to the special scheme according to which it is connected: LEDs are connected in series only within one group - and the groups themselves, in turn, are connected in parallel. Cut the long tape into short pieces only at the points marked by the manufacturer.

Since the LED is a polar semiconductor, polarity reversal will only lead to the fact that it does not light up. Modern LEDs released over the past few years have reached a brightness (light flux intensity) that goes up to 150 lumens per unit. With a properly selected current, LEDs can last up to 50,000 hours, moreover, they are not demanding on operating conditions. The disadvantage of LEDs is the need for direct current (they wear out ten times faster from alternating current), a gradual decrease in the brightness of the glow (when the service life declared in advertising is exceeded) and high cost.

LEDs are, one might say, a profitable investment in the future, but only with strict adherence to the calculated characteristics will they last as long as the manufacturer promises. If simple LEDs can be re-soldered (replaced worn out), and a simple light bulb can be outweighed, then the LED strip, when transferred to another place, will lose its self-adhesive properties and will fit only when installed in a transparent hose of small diameter.

Types and models

Standard (open) LED strips have an IP-40 moisture protection class (not protected from splashes and moisture). They are useful only in ordinary rooms - in the hallway, bedroom, study, under a canopy in the yard, etc. Waterproof, IP-65/68 class, designed for damp rooms with an aggressive environment, as well as for rainy street conditions.

However, moisture protection is also different - a partial covering from moisture (most often transparent silicone) will fit somewhere on the ceiling of a bathroom or shower, but not suitable for underwater lighting in a jacuzzi or pool.

The underwater tape, in turn, has a continuous and sealed coating that protects it from water penetration. It can be used even when submerged under water to a considerable depth - for example, by divers and divers: such a tape is installed in a special headlamp, tightly insulated from water penetration under its body. Street tapes are especially bright - they have serious requirements for light output. Tapes for the room are distinguished by a wide spread in light flux and power: for everyday work in the dark, high-power ones (up to tens of watts) will come off, and as a night light - their short sections with a capacity of up to several watts.

Monochrome tapes include products based on SMD-5050 and SMD-3528 LEDs. These are strips with 30 ... 60 LEDs per running meter of tape. If we measure the area of the luminaire in square meters, then, taking into account their placement density, the number can reach thousands of light elements per "square". Heterochromic and polychrome tapes are equipped with separate microcontrollers for each cluster or sector. Those, in turn, receive a signal and power from the main unit, in which the "head" controller setting the luminescence mode is set. Thanks to these features of the scheme, such a tape can glow in almost any of the shades.

So, the tape based on the SMD-3528 assembly has a single-channel microcircuit - with dimensions it is offered with a single-channel chip. Its dimensions are 3.5 x 2.8 x 1.9 mm. The SMD-5050 product has three-channel microcircuits - three LEDs (red, green and blue) are "planted" on one microcircuit. White color is formed due to the simultaneous glow of red, green and blue components. The form of release is a coil with a tape wound on them, a segment is 5 m long. The SMD-3528 model has a centimeter width, the SMD-5050 is somewhat thinner: only 8 mm.

How to glue?

The surface on which the diode tape is glued must not be a dusty environment. So, for gluing self-adhesive tapes, a wall covered with whitewash or glued with pulp and paper wallpaper is not suitable. Plastic and metal must be thoroughly washed and dried.

If necessary, degrease with alcohol, acetone or another solvent that does not dissolve the plastic itself (or a layer of paint / varnish).

Gluing the tape is very simple: the required piece is cut off, at the beginning of which the wires are soldered for power supply, then the protective film is removed from the end. The end is attached to the starting point of the gluing. Then, gradually removing the protective film, the tape is pressed along the removal of this film - in a straight line passing through the gluing plane. A meter of tape can be glued in less than a minute - the more experience the master has, the sooner he will get the job done.

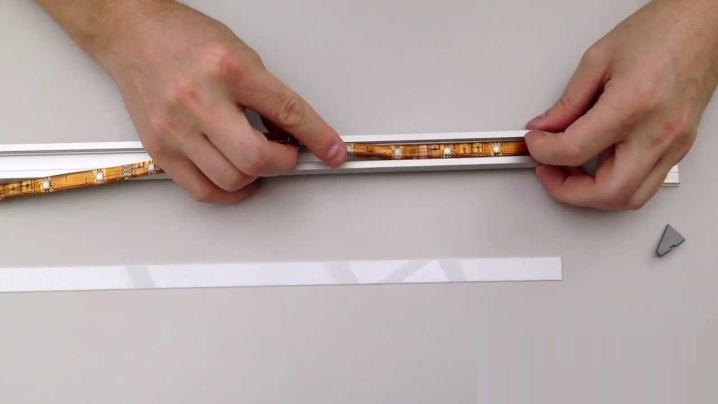

Since the tape may heat up somewhat during operation, aluminum has the best heat-dissipating properties. Bonding tapes that do not have an adhesive layer under the protective film is done using thermal paste - it conducts heat relatively well compared to the same plastic. Since the aluminum profile is not cheap, the tape can be glued into the plastic cable duct without a cover.

The disadvantage of plastic is its low thermal conductivity. So that the LEDs do not prematurely burn out from constant overheating, they have to be turned on at a reduced brightness, applying a voltage, for example, equal to 9 ... 11 volts (for 12-volt tapes) or 3.7 ... 4.2 (for 5-volt). An alternative to plastic is polished and varnished wood of any species. Tapes that do not have an adhesive layer are glued to almost any surface. The Moment-1 glue will serve as a universal solution here.For the highest quality fixation, the tape is pressed down in places free of ballast resistors and LEDs.

How to connect?

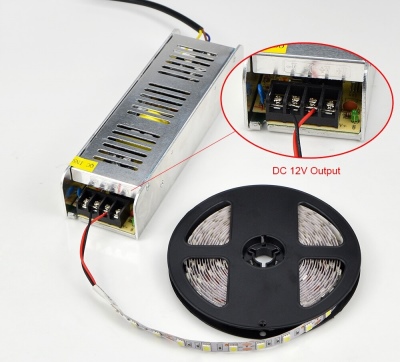

Connection to a 220 V AC network is allowed only with any adapters in which an AC rectifier is present. And this is achieved only with the help of conventional high-voltage diodes, designed for hundreds of volts. In the simplest case, the power source is a transformer power adapter. It provides galvanic isolation with voltage drop from 220 to 3 ... 12 volts. The best option is a regulated regulated power supply. All modern power supplies operate on a pulse (non-linear) principle.

For 5-volt tapes, even "charging" from a smartphone or tablet is suitable, giving out just such a voltage. This charger is rated for up to 2 amps. The current consumption is easy to calculate: the power divided by the supply voltage will give the number of amperes of current.

For example, a 6 watt strip of tape (6 x 1 watt LEDs) will load a 2 amp 1.2 amp charger.

However, the power reserve should also take into account the current loss for heat from the LEDs and from the adapter itself. It is simple to connect the LEDs: it is only important not to confuse the polarity of the adapter output (5 V or 12 V) and the input of the LED strip.

The comment was sent successfully.