All about 12 volt LED strips

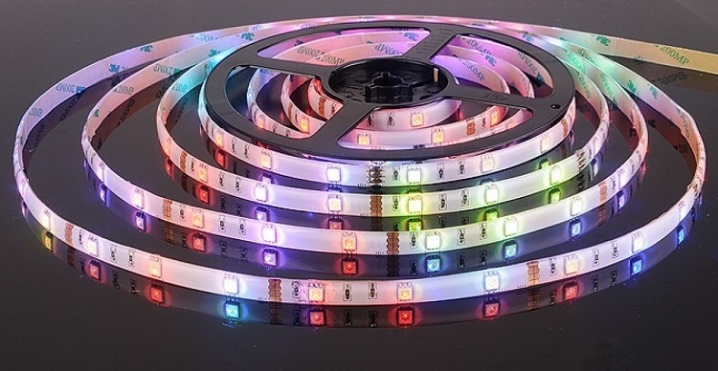

In recent years, LEDs have replaced traditional chandeliers and incandescent lamps. They are compact in size and at the same time consume negligible amount of current, while they can be fixed even on the narrowest and thinnest boards. The most widespread are LED strips powered by a 12 volt unit.

Device and characteristics

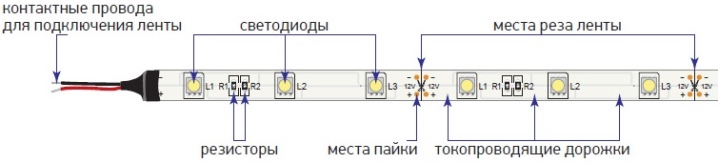

LED strips look like a solid plastic board with built-in LEDs and other microelements needed to support the functional circuit... Direct light sources can be placed in one or two rows with equal steps. These lamps consume up to 3 amperes. The use of such elements makes it possible to achieve uniform dispersion of artificial illumination. There is only one drawback of 12V LED strips - a high price compared to other lighting sources.

But they have much more advantages.

- Ease of installation. Thanks to the adhesive layer on the back and the flexibility of the tape, installation on the most difficult substrates is possible. Another advantage is that the tape can be cut according to special marks - this greatly simplifies the process of fixing them.

- Profitability... Electricity consumption when using LEDs is much lower than that of traditional incandescent lamps.

- Durability... If the installation is carried out in compliance with all the rules and regulations, then the diodes burn out extremely rarely.

Nowadays, stores offer LED strips with any saturation and luminescence spectrum. If necessary, you can even buy a tape with a controller on the remote control. Some models are dimmable, so that the user can change the brightness of the backlight depending on personal preferences.

Where are they used?

12 V diode tapes these days are ubiquitous in a variety of areas. Low voltage makes them safe, so they can be operated even in damp rooms (kitchen or bathroom). LEDs are in demand when arranging the main or additional light in apartments, garages and in the local area.

This type of backlight is also suitable for car tuning. The backlighting looks very stylish on the line of the sills of the car, giving it a truly fantastic look at night. In addition, LED strips are often used for additional illumination of the dashboard.

It is no secret that the products of the domestic auto industry of old issues do not have daytime running lights - in this case, the LEDs become the only available output. However, in this case, it must be remembered that only yellow and white bulbs correspond to this goal. The only difficulty in operating diode strips on vehicles is the voltage drops in the on-board network. Conventionally, it should always correspond to 12 W, but in practice it often reaches 14 W.

Tapes that need a stable power supply under these conditions can fail. Therefore, auto mechanics recommend installing a voltage regulator and stabilizer in the car, you can buy it at any point of sale of auto parts.

Views

There is a wide range of LED strips. They are divided by shade, luminescence spectrum, types of diodes, density of light elements, flux direction, protection criteria, resistance and some other characteristics.They can be with or without a switch, some models run on batteries. Let's dwell on their classification in more detail.

By intensity

An important criterion for choosing a backlight is the brightness of the LED strips. It contains all the basic information about the intensity of the flux emitted by the LEDs.

The marking will tell about it.

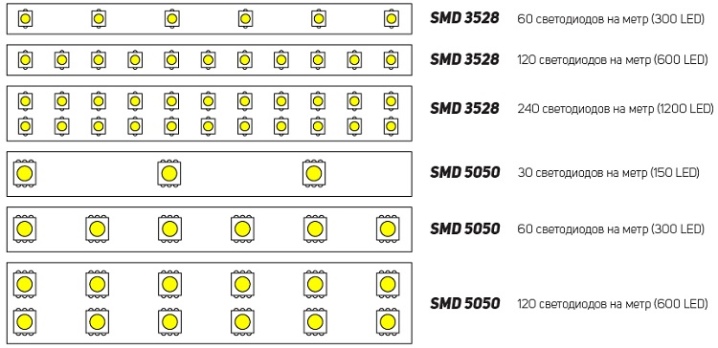

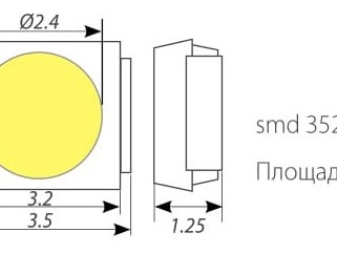

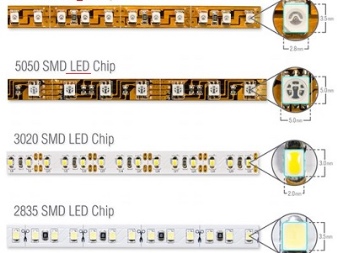

- 3528 - tape with low luminous flux parameters, each diode emits about 4.5-5 lm. Such products are optimal for decorative lighting of shelves and niches. In addition, they can be used as auxiliary lighting on multi-tiered ceiling structures.

- 5050/5060 - a fairly common option, each diode emits 12-14 lumens. A running meter of such a strip with a density of 60 LED easily produces 700-800 lumens - this parameter is already higher than a traditional 60 W incandescent lamp. It is this feature that makes diodes popular not only for decorative lighting, but also as a basic lighting mechanism.

In order to create comfort in a room of 8 sq. m., you will need about 5 m of this type of tape.

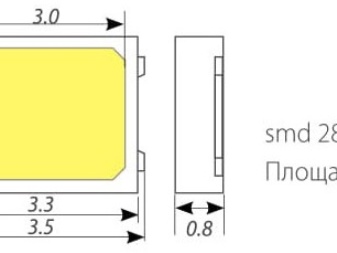

- 2835 - a fairly powerful tape, the brightness of which corresponds to 24-28 lumens. The luminous flux of this product is powerful and at the same time narrow directivity. Due to this, tapes are indispensable for highlighting isolated functional areas, although they are often used to illuminate the entire space. If the tape serves as the main lighting device, then for 12 sq. m. you will need 5 m of tape.

- 5630/5730 - the brightest lamps. They are in demand when lighting shopping and office centers; they are often used for the manufacture of advertising modules. Each diode can produce narrow beam intensity up to 70 lumens. However, it must be borne in mind that during operation they quickly overheat, therefore they require an aluminum heat exchanger.

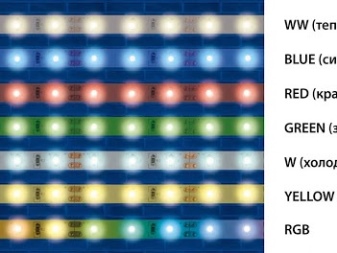

By color

6 primary colors are used in the design of LED strips... They can have different shades, for example, white is neutral, warm yellowish, and also bluish. In general, products are divided into single and multi-color. The single color strip is made of LEDs of the same illumination spectrum. Such products have a reasonable price, they are used to illuminate shelves, stairs and hanging structures. Multicolor stripes are made from diodes based on 3 crystals. In this case, the user can change the heat of the emitted spectrum using the controller.

It also allows you to control the intensity automatically, as well as activate and deactivate the backlighting system at a distance. MIX LED strips are very popular. They include a variety of LED lamps, emitting a variety of shades of white, from warm yellowish to cold bluish. By varying the brightness of the illumination on individual channels, it is possible to change the overall color picture of the illumination.

The most modern solutions are D-MIX stripes, they allow you to form shades that are ideal in terms of uniformity.

By marking

Any LED strip necessarily has a marking, on the basis of which you can determine the basic characteristics of the product. A number of parameters are usually indicated in the marking.

- Lighting device type - LED for all diodes, thus the manufacturer indicates that the light source is LED.

- Depending on the parameters of the diode tape, the products can be:

- SMD - here the lamps are located on the surface of the strip;

- DIP LED - in these products, the LEDs are immersed in a silicone tube or covered with a dense layer of silicone;

- diode size - 2835, 5050, 5730 and others;

- diode density - 30, 60, 120, 240, this indicator indicates the number of lamps on one PM tape.

- Glow spectrum:

- CW / WW - white;

- G - green;

- B - blue;

- R is red.

- RGB - the ability to adjust the tint of the tape radiation.

By level of protection

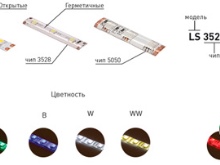

An important factor to consider when choosing an LED strip is the protection class.This is true in cases where the lighting device is planned to be mounted in rooms with high humidity or outdoors. The degree of security is indicated in alphanumeric form. It includes the abbreviation IP and a two-digit number, where the first number stands for the category of protection against dust and solid objects, the second stands for resistance to moisture. The larger the class, the more reliably the strip is protected from external adverse influences.

- IP 20- one of the lowest parameters, there is no moisture protection at all. Such products can only be installed in dry and clean rooms.

- IP 23 / IP 43 / IP 44 - strips in this category are protected from water and dust particles. They can be installed in low-heated and humid rooms, they are often used for running along the baseboards of the floor, as well as on loggias and balconies.

- IP 65 and IP 68 - waterproof sealed tapes, closed in silicone. Designed for use in any moisture and dust. They are not afraid of rain, snow and temperature fluctuations, so such products are usually used on the streets.

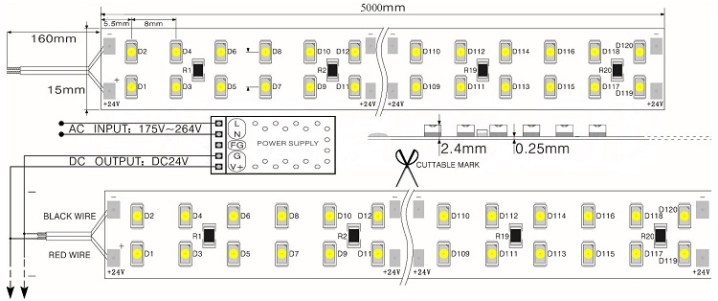

To size

The dimensions of LED strips are standard. Most often they buy SMD 3528/5050 LEDs. At the same time, one linear meter of tape 3528, depending on the degree of density, can accommodate 60, 120 or 240 lamps. On each running meter of the strip 5050 - 30, 60 or 120 diodes. Ribbons can vary in width. On sale you can find very narrow models - 3-4 mm. They are in demand for creating additional illumination of walls, cabinets, shelves, ends and panels.

How to choose?

People who do not have much experience with lighting fixtures have difficulty buying LED strips. The first thing to focus on is the permissible modes of use. If you need a strip to organize the main lighting, it is better to give preference to models in yellow or white. For backlighting or lighting zoning, you can choose from color models of the blue, orange, yellow or green spectrum. If you prefer changing backlighting, RGB strips with a controller and a remote control will be the optimal solution.

The next factor is the conditions in which the tape will be used. For example, for laying in a bathroom and a steam room, equipment with a class of at least IP 65 is needed. Pay special attention to the manufacturing companies. So, budget Chinese products are widely represented on the market. They attract with their cost, but at the same time they are extremely fragile.

The service life of such diodes is short, which leads to a decrease in the intensity of the luminous flux. They often do not meet the declared performance characteristics. Therefore, when buying a light strip, you must definitely require a certificate of conformity and basic technical documentation.

High quality elements must have the following characteristics:

- 3528 - 5 Lm;

- 5050 - 15 Lm;

- 5630 - 18 lm.

How do I shorten the tape?

The tape is sold by the footage... Taking into account the parameters of the density of the installation, a different number of diodes can be located at each PM. Without exception, all LED strips have contact pads, they are used to build up the strip in case it is necessary to assemble the backlight from separate pieces. These sites have a special designation - the scissors sign.

On it, the tape can be reduced by cutting into small sections. In this case, with a maximum strip length of 5 m, the minimum segment will be 5 m... The strip is designed in such a way that individual sections of the LED strip can be soldered using LED connectors. This approach significantly speeds up the switching of different segments into a single chain.

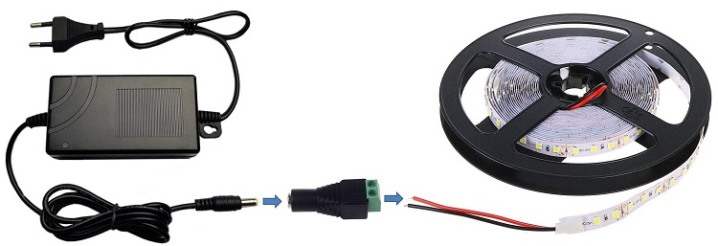

How to properly connect to the power supply?

The work of connecting an LED strip through a power supply may seem simple. However, novice craftsmen, installing the backlight at home, often make mistakes. Each of them leads to an early failure of the lighting device. There are two most common reasons for strip breakage:

- poor quality tape and power supply;

- non-observance of the installation technique.

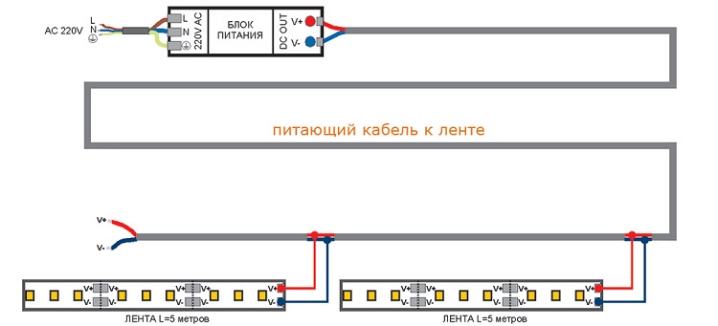

Let's describe the basic scheme for connecting the tape.

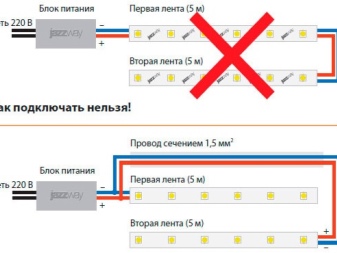

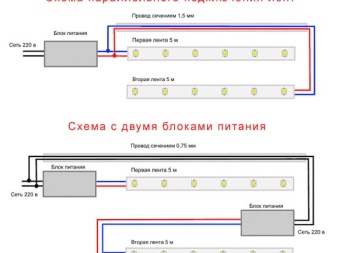

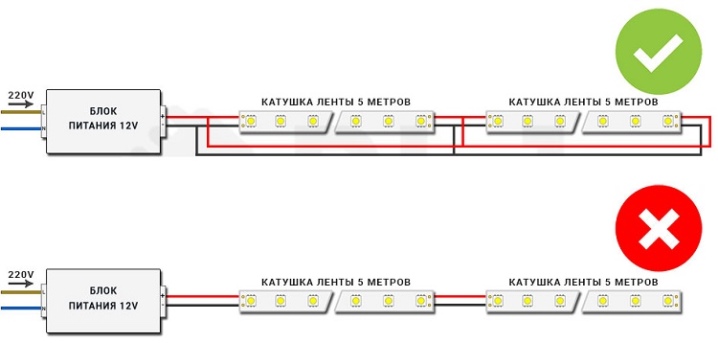

Band connects parallel - so that the segments are no more than 5 m. Most often, it is sold with coils of the corresponding meter. However, there are situations when it is required to connect 10 and even 15 m. Often in this case, the end of the first segment is mistakenly connected to the beginning of the next - this is strictly prohibited. The problem is that each current-carrying path of the LED strip is oriented to a strictly defined load. By connecting two strips together, the load at the edge of the tape is twice the maximum allowable. This leads to burnout and, as a result, system failure.

In this case, it is better to do this: take an additional wire with a diameter of 1.5 mm and connect it with one end to the power output from the first block, and the second to the power supply of the next strip. This is the so-called parallel connection, in this situation it is the only correct one. It can be done through an adapter from a computer.

You can connect the tape only on one side, but it is better on both sides at once. This significantly reduces the load on the current paths, and also makes it possible to minimize the unevenness of the glow in different parts of the diode strip.

In conditions of high humidity, the LED strip must be mounted on an aluminum profile, it acts as a heat sink. During operation, the tape overheats greatly, and this has the most unfavorable effect on the glow of the diodes: they lose their brightness and gradually collapse. Therefore, the tape, which is designed to work for 5-10 years, without an aluminum profile will burn out a maximum of a year later, and most often much earlier. Therefore, the installation of an aluminum profile when installing LEDs is a prerequisite.

And of course, it is important to choose the correct power supply, since it is he who becomes a guarantee of safe and long-term operation of the entire backlight. In accordance with the installation rules, its power should be 30% higher than the corresponding parameter of the LED strip - only in this case it will function correctly. If the parameters are identical, then the unit will work at the limit of technical capabilities, such an overload reduces its service life.

The comment was sent successfully.