LED strip controllers

It often happens that the use of LED strip to illuminate the space is not enough. I would like to expand its functionality and make it a more versatile device. A dedicated controller for the LED strip can help with this. A similar controller for LED backlighting can have different functionality. The latter will depend on its purpose and technical features, as well as the number of colors of the device, the frequency of dimming and other indicators. Let's try to figure out what kind of device it is, how to choose it, what it is and how to connect it.

What it is?

It should be said that no controller is needed for a single-color ribbon. It is simply plugged into a power source, which is typically used for 12 volt devices. If the tape can handle high voltages, then an appropriate power source should be selected. The most common models will be for 12 volts (+ 220) and for 24 V. There are, of course, options that are generally connected to the network directly, but they do not exist in the RGB variation.

And if we say exactly what a controller is, then it is a device responsible for switching circuits from a power source to a consuming device.

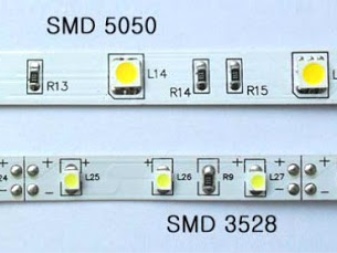

There are 3 LED rows on the strip, which differ in color, or 3 colors are made as a separate crystal in a single case, for example, option 5050:

- green;

- blue;

- Red.

Note that the controllers can have different designs, including sealed ones. Therefore, they have different indicators of protection against water and dust. There are no switches or keys on the controller. Therefore, usually such a diode strip device is supplied with a remote control. Such an IR controller is an excellent solution for controlling ribbons based on LEDs of various types.

Species overview

There are different controllers. They differ according to the following criteria:

- control method;

- type of execution;

- installation technique.

Let's say a little more about each criterion, and what, depending on it, the controllers for LED-type lamps can be.

By type of execution

If we talk about the type of execution, then the controllers for LED boards according to this criterion can be those where the control unit is equipped with some kind of protection or similar protection will be absent on it. For example, they can be IPxx water and dust resistant. Moreover, the simplest type will be IP20 protection.

Such devices cannot be used outdoors or in rooms with high humidity.

The most protected type of device will be IP68 models. In addition, tapes can also have different degrees of protection. They are marked accordingly.

By installation method

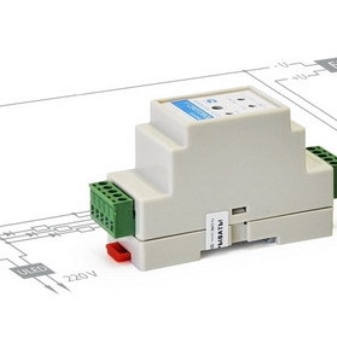

For this criterion, a multichannel controller for RGBW and other devices can have a housing with special holes for bolts or a special DIN rail. The latest models are considered the most successful option for placement in electrical panels.

By way of control

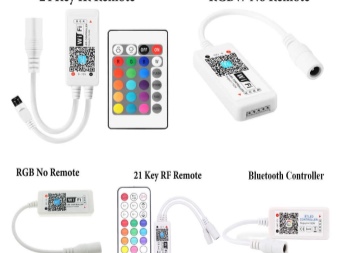

If we talk about the control method, then the considered category of devices can have a lot of variations. For example, there are models that can be controlled from the phone using Wi-Fi and Bluetooth technologies. There are also IR controllers, which, in terms of control technology, are somewhat similar to a TV remote control. Particularly popular is the infrared music audio controller, which can have various functions.

By the way, models that have a remote control in the kit make it possible to select the auto mode, as well as manually set the brightness and color gamut. But more precisely, different models have different connection and control features. Therefore, when choosing, you should carefully read the characteristics of the products so that they contain functions that are of interest to a particular user.

Popular models

If we talk about popular models of controllers for LED strips, then it should be said that a huge number of different products are presented on the market today, which can be called a good solution in terms of price and quality ratio. But I would like to highlight one that will be especially interesting.

This is a model from the manufacturer Lusteron, presented in the form of a small white box with wires. The recommended wattage is 72W, although it can handle 144W max. The input current here will be at 6 amperes, that is, 2 amperes per channel.

At the input, it has a standard 5.5 by 2.1 mm 12-volt connector, which, according to the manufacturer, can operate in the power supply range from 5 to 23 volts. The body of the device is made of polycarbonate materials.

Note the presence of voice control through services such as Tmall Elf, Alexa Echo and, of course, Google Home. This device can not only be controlled from your smartphone, but also remote control is available using the Internet. This will be very convenient if the owner is not at home. The device is equipped with a timer mode, according to which you can turn on and off yourself. In addition, brightness control of the connected LED strip is available here.

It should also be noted that the device is complete, which includes the controller itself, a spare 4-pin adapter, as well as a box and a manual. Unfortunately, the manual is not very clear, which is typical for many products that are made in China. But there is a link there, by clicking on which, you can download the application to your smartphone to control the controller.

It is a product of Tuya, a company that specializes in creating software specifically for the Internet of Things.

The application is made with high quality and displays all available functionality. There is a Russian language here, which will allow even an inexperienced user to easily understand all the intricacies of controlling the device in question from the Lusteron brand. Although some translation inaccuracies still occur, this is not too critical. In general, it should be said that the device turned out to be quite good in terms of its characteristics, it has good functionality and is not too expensive.

Nuances of choice

If we talk about choosing a controller for LED strips, then the first aspect to dwell on is voltage. Its value should be identical to that of the power supply, because we are talking about a switched-type voltage. You should not connect the programmable controller to a 24 V circuit. Of course, the device can and will work with such a power supply, but not for long. Or it will simply burn out right away.

The second important parameter for choosing a programmable controller is current. Here you should clearly understand what specific length the tape will be, and calculate the current that it will consume. For example, the most common type of tape 5050 will need about 1.2-1.3 amperes per 100 centimeters.

An important point that will also help you choose a model of the type of device in question is marking. Usually it looks like this: DC12V-18A. This means that the controller model has 12 volts of voltage at the output and produces a current of up to 18 amperes. This point also needs to be taken into account when making a choice.

By the way, if for some reason it is impossible to purchase a programmable controller for the required current level, then an amplifier can be used.

It uses signals from the main controller or the previous tape and, with the help of an additional power source, can turn on the backlight according to a similar controller algorithm.

That is, it amplifies the controller signal so that it is possible to connect more lighting devices using an additional power source. This will be especially in demand if it is necessary to install a very long installation, and such a solution will make it possible not only to save the wire, but also reduce the time spent on the separation of power lines, because the additional power source operates from a 220 volt network.

It should be added that all parts of the circuit must be selected for the same current and voltage, and the consumption current cannot be greater than the current, which is provided by the power supply and the controller.

The last point that you need to pay attention to when selecting is the design of the case. It should be clearly understood where the device will be mounted. If this will be done, say, in a room where there is no high humidity and temperatures, then there is no point in buying models of power supplies and controllers that are tight and resistant to moisture.

Connection

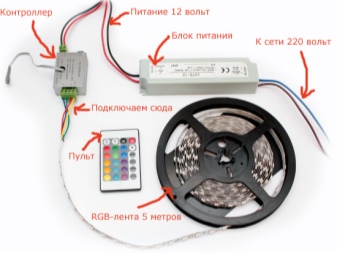

If we talk about connecting the controller to the mentioned type of LED strip, then it would be best to do this using special connector connectors. Typically, the unit has the following connector markings:

- Green-G - green color;

- Blue-B - blue;

- Red-R - red;

- + Vout- + Vin - plus.

The connection scheme will be implemented according to the following algorithm:

- the required elements should be prepared - LED strip, connectors, power supply and controller;

- in accordance with the color scheme, it is required to connect the connector and the tape;

- select the designation of the terminals on the power supply and connect the connector in such a way that the ribbon contacts completely coincide with the controller ones;

- connect the power supply through the terminal blocks on the other side of the unit or using a male-female connection (the possibility of this or that type of connection will depend on the design features of the connector and the power supply);

- check the quality and reliability, connect, and then connect the assembled circuit to the network;

- check the performance of the resulting structure.

It should be added that sometimes controllers differ in design, according to which multi-zone connection of LED strips is carried out. Then the principle of installing the components will be the same, except for the moment that this must be done sequentially for each zone.

Controllers for LED strips in the video below.

I recently bought tape controllers.

The comment was sent successfully.