What are LED strips and how do they work?

LED strips made a splash in interior design, architecture, construction. From the material in this article, you will learn what they are, what they are equipped with, how to choose and connect them correctly.

Peculiarities

LED strips - unique lighting designs with easy installation... This equipment works, like any LED lamp, due to the possibility of emitting semiconductor p-n junctions when current passes.

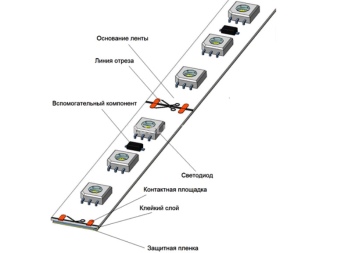

The circuit consists of several elements, including the conductors themselves, resistors, a strip base, and a contact pad. The base of the tape is made of a dielectric material with a thickness of 0.2-0.5 mm.

It contains paths that conduct current, and platforms with LEDs and current limiters. The light emitters are the LEDs themselves. The width of the base can vary within 0.8-2 cm and more, it consists of many segments.

Tapes belong to such light sources that they are produced in the form of a flexible printed circuit board with LEDs and additional radio components located on it. The LEDs are located on the module with equal pitch.

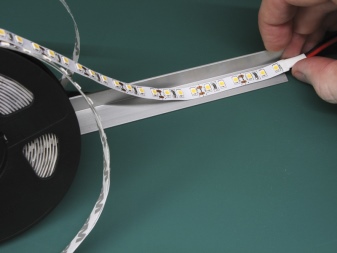

The second side of the tape has an adhesive backing. Thanks to it, the installation of lighting is simplified. The tape is practical, elastic, and provides cutting along specially designed lines. This allows it to be mounted even in hard-to-reach places.

Flexible LED strip uses a minimum of electricity. It is safe to use and has a long service life. It adheres perfectly to a smooth surface, allows you to choose the most accurate length, has a wide range of colors.

Along with this, it needs the use of drivers (auxiliary power supplies). Low power ribbons do not replenish the level of the main light. If you use tapes with the right amount of lighting, the price will exceed the cost of conventional light sources.

Views

There are several types of LED strips. Each product group has its own differences and characteristics. For example, products supplied to the domestic market differ in size, the number of LEDs per 1 m and other technical characteristics.

Based on the location of the light emitters, they are front and end.

The variants of the first type are distinguished by a light scattering angle of 120 degrees. For analogs of the second group, it is straightforward.

On sale there are varieties with other scattering angles. Their task is to focus the light beam on specific objects. LED strips have different levels of tightness, type of section. They are selected based on the purpose and conditions of use.

By execution

Depending on the version, flexible strip lighting is available in single row, ultra-narrow, wide and ultra-wide. Each type of lighting device is characterized by its own characteristics. Single-row ones have a narrow board 0.8-1.3 cm wide, 0.24-0.55 cm thick, 5 m long (based on the type of diodes and protection class). The width of ultra-narrow analogs does not exceed 0.5 cm.

They are fixed in the most inaccessible places.

The wide boards are 1.5-5.8 cm wide. Several rows of diodes are built into them. The staggered arrangement of the light emitters ensures a uniform glow. The length of such tapes is 2-5 m. They have the best color rendering index.

In addition to basic ribbons, there are varieties with a side glow type on sale. These diodes are cylindrical in shape and are attached to the end of the board. The plane is illuminated in the longitudinal direction.

Among other types, ribbons with a curly or petal plate are produced. The first type of flexible backlight flexes perfectly in different directions. It is used to illuminate figures of complex curvilinear shapes.

The difference between the angular 3D strip with a petal plate is the ability to change the rotation of the platform with a diode in the range from 0 to 90 degrees. It is illuminated by volumetric luminous letters, as well as shop windows. The flexible, hermetically sealed tape features a matte silicone coating.

It bends perfectly in any direction, thanks to which it is used when installing contour lighting.

By LED type

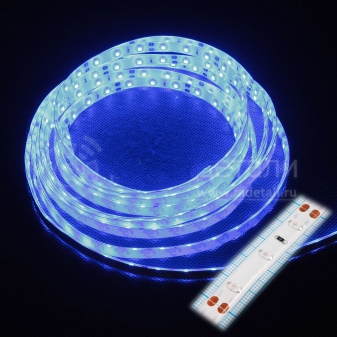

The type of diodes determines their size and brightness. Tapes are produced using SMD and DIP technologies. The first type of LED consists of a housing that removes heat, contacts, a contact wire, a semiconductor crystal and a lens.

Based on the design of the tape, 1-3 diodes can be located on the substrate. The sizes of the elements may vary. The most popular products are SMD 3528, 2835, 3014, 5050, 5630.

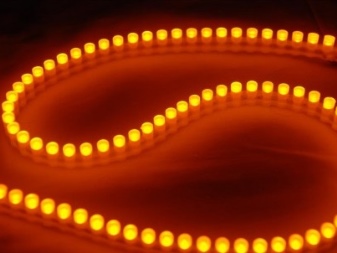

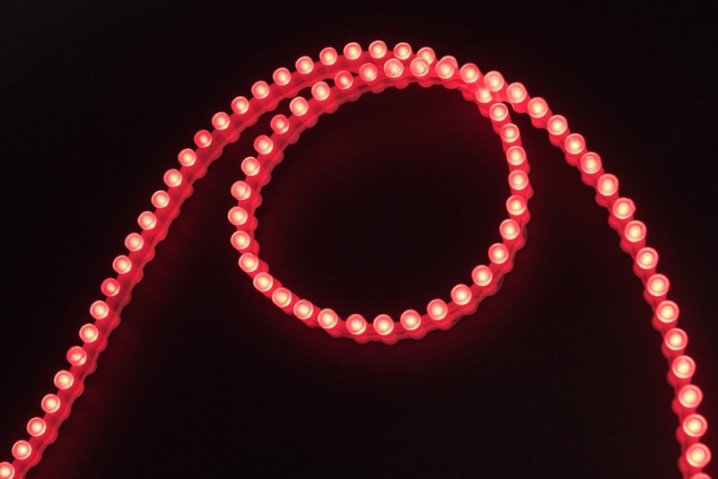

DIP analogs are placed in a double line. They are referred to as indicator diodes. These are semiconductor crystals placed in lenses that create beams of light. The circuit includes a printed circuit board, contacts, a contact wire.

These types of diodes heat up less during operation. Have sufficient power and brightness. They are purchased for indoor lighting of electronic boards, creeping lines.

The visual differences between the two different types are in performance. SMD tape is flat, the DIP version is similar to beads, consisting of cylindrical diodes attached to the base.

By color

The tint of the tape is a key characteristic. It can be single-color or multi-color. Varieties of the first group under voltage are capable of emitting 1 color. Basic tones include white, blue, red, yellow, green. They are considered basic.

In addition to them, there are products on sale with purple, pinkish-crimson, blue-green, orange shades of the luminous flux.

White ribbons, in turn, are divided into 3 types. According to the temperature of the emitted light, they are cold, warm and neutral. The color temperature is indicated on the marking in degrees Kelvin.

Monochromatic base tone backlights emit brighter light than SMD counterparts with intermediate tone diodes. The second types of light sources are used as decorative lighting.

Multi-color RGB strips work with different controls. Addressable views are distinguished by the ability to control the glow color of each diode separately. They are called smart tapes.

By the level of the supply voltage

Based on the type of supply voltage, tapes of 220, 36, 24, 12, 5 volts are distinguished. Most demanded - varieties for 220 and 12 V. In addition to them, there is a demand for products operating from an alternating current network with a voltage of 220 V without a power supply. It is connected to the mains using a diode bridge adapter.

In the lines of individual manufacturers, there is a flexible backlight that runs on AAA or AA batteries.

By installation method

Self-adhesive products are available with two types of LEDs: SMD 3028 and SMD 5050. The four-digit numbers following the letters indicate the length and width dimensions in mm. LED strips are attached to an adhesive base directly to the prepared bases or to profiles, which are subsequently screwed into place.

The mount itself can be open and hidden. The tape is glued to the moldings, plinth, under the furniture. In addition, it is mounted along the contour of drywall, creating the effect of floating figures.

It is also embedded inside the tensioning fabric. This creates an extraordinary type of auxiliary lighting when creating a design lighting solution. UV tapes are different from traditional UV lamps.

Marking

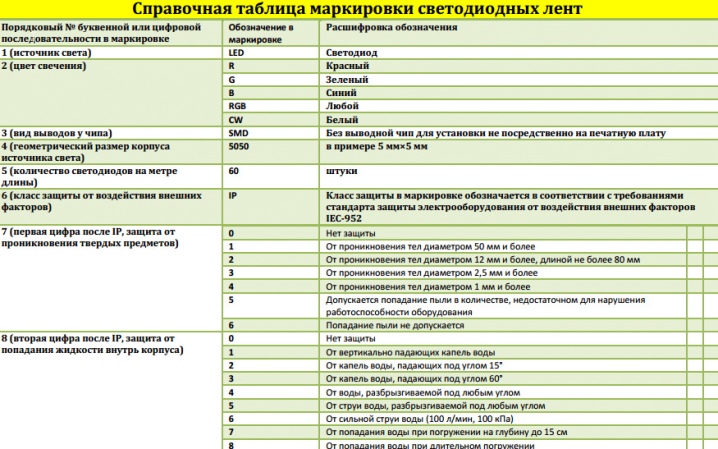

Marking - a brief description of the characteristics specified by the manufacturer. It's pretty tricky. The list of standard designations includes an indication of the type of tape, type and parameters of built-in light emitters.

In addition, it indicates the supply voltage, the shade of the glow, the row and density of the diodes, their number per 1 running meter. In other varieties, the marking also shows the shade of the substrate.

It is not difficult to decipher the marking, consisting of a set of letters and numbers:

- the first letters are the type of diodes used (SMD or DIP);

- 4 numbers by letters - dimensions of the used light emitters in mm (35x28, 50x50, 56x30);

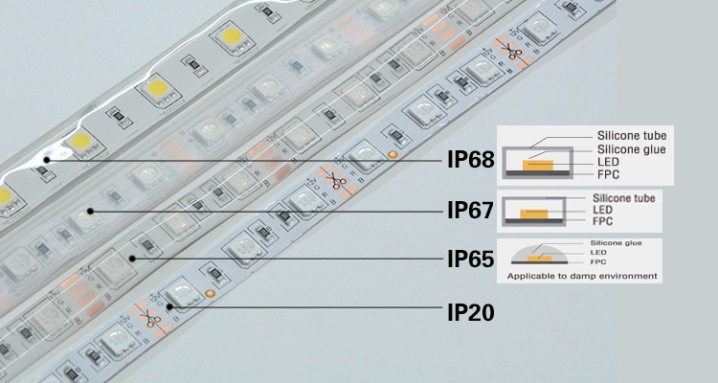

- IP indicates the protection class according to the standards;

- numbers behind two letters - open or closed tape.

In most cases, products are manufactured outside of Russia, which is why when buying, you have to focus on foreign standards. Typically, the label indicates IP (Ingress Protection).

The first number behind the letters indicates protection against damage and dust. The better it is, the higher the protection class:

- at zero, there is no protection against accidental breakdowns;

- one indicates a weak level of security;

- six is the best option with maximum protection.

The second number is an indicator of moisture resistance.

The lower its value, the more careful attitude it requires.

For example, tape marked IP20 can only be used in dry rooms. It is placed where foreign objects cannot get onto the board.

Products with IP65 ratings can be used for outdoor advertising, car interiors and bathrooms. However, it is not immune to harsh chemicals.

IP68 tape - the version with the best level of tightness... It can be used underwater, up to a depth of 1 m (for example, to illuminate swimming pools and saunas).

Components

For the installation of LED strips, plastic and aluminum profiles are used. At the place of installation, the guides are divided into 3 types: angular, built-in (cut-in), overhead.

- Varieties of the first type are equipped with a removable diffuser. It protects the eyes by leveling the brightness of the diodes up to 25-40%.

- The inline view profile is for design purposes. Often connects drywall and chipboard. It is mounted flush or with a small protrusion above the surface.

- The cut-in profile has an edge that hides irregularities in the places of the grooves. It is used to illuminate work surfaces (for example, kitchens), and also as an insert in the baseboard, creating the effect of floating furniture.

- The cover profile is suitable for mounting on any kind of surface. The type of fastening varies (you can glue and fasten with self-tapping screws). Suitable for fixing on arched and curved surfaces.

To connect several strips, connectors are purchased. In addition to them, they buy an auxiliary wire. It is used in the case of mounting the illumination of the working area, divided by the hood.

If the tapes have a low output voltage, they purchase a power supply that serves as a step-down converter and current rectifier. These devices are different (for rooms with low or high humidity levels).

When connecting the power supply to an outlet, a plug is obtained. When you plan to change the intensity of the white backlight, buy a dimmer or an auxiliary switch with it.

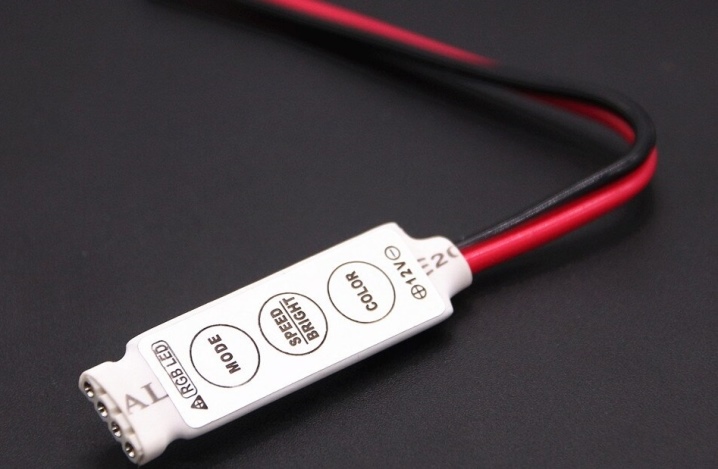

When editing RGB tape, use a controller... It is needed to switch the shade of the glow and change its brightness. Typical devices are designed for tapes 15 m long. If the strip length is longer, you will have to purchase an RGB amplifier.

A switch is also a necessary element. By the type of control, it can be push-button, touch-sensitive and infrared, responsive to hand movements.

Nuances of choice

When choosing one or another type of flexible LED strip, a number of nuances are taken into account. The key is the level of protection.

1 m of a standard tape can accommodate 30, 60, 90, 120, 240 chips.To increase the volume of the luminous flux, the diodes are arranged in 2, 3 and even 4 rows. The more diodes on the base, the more power and the higher the brightness.

When buying the best tape, take into account the purpose of use, the type of product, color, directionality and brightness of the glow... They also pay attention to the protection class, installation density, manufacturer's reputation and customer reviews.

The length of the standard white options is 5 m. In addition, products of 10, 15, 20, 25 meters are sold in reels. This allows you to make the optimal purchase for the installation of the product on a large area.

In retail outlets, tapes are sold both separately and in the form of ready-made sets. In addition to the strips themselves, a power source is included in them, and in the colored varieties - a dimmer with a PU.

When choosing an option for the home, pay attention to the brightness. Not only performance, but also mood will depend on the ability of the tape.

It should not shine too dimly or, on the contrary, sharply.

It is also necessary to take into account the fact that with an increase in the density of the placement of diodes, the heat release from the working diodes increases.... This can cause overheating. Therefore, you need to carefully consider the choice of a profile.

Heavy duty tapes must be attached to the aluminum profile. It will dissipate heat efficiently. Models of the four-row type are placed on copper substrates in order to prevent overheating.

When selecting the directivity of the light flux, pay attention to the placement of diodes on the substrate. In this regard, front-facing models with the ability to scatter light by 120 degrees are considered the best.

Side lighting is used primarily for decorating objects. She emphasizes their contours.

Applications

LED strips have a wide range of uses. Examples of exploitation are extensive... Due to their compactness and flexibility, the tapes are able to repeat complex geometric shapes.

They are used to decorate the interior, they are on duty, as well as emergency lighting of various types of premises. Facades of buildings are decorated with diode ribbons. Today they have become a replacement for central lighting. They perfectly cope with the illumination of individual functional areas, showcases, shelving structures. They are mounted on ceilings, furniture facades, mirrors. They are favorably decorated with accent walls of dwellings, they are attached to the windows.

They are used for highlighting goods in showcases of retail outlets and banners. Used for decorative and functional lighting of niches, shelves, stairs. With their help, they compensate for the lack of light when growing seedlings. They are used in greenhouses, greenhouses. They are used to decorate houses during events, significant events and holidays (for example, New Year's, birthdays, anniversaries), decorate aquariums, and elements of interior design.

By means of this illumination, they accentuate exhibition areas, decorate squares, gardens, billboards.

It can be used indoors and outdoors.

Connection

The LEDs on the tape are arranged in groups of several. Before making the connection, the tape is cut at the junction of these groups. The cutting points are marked with a dotted line and drawn scissors.

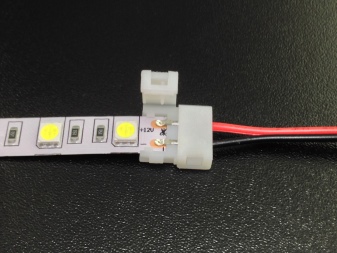

At the joints there are special contact pads of the same size for soldering or connecting connectors. If the tape is cut in other places, the diodes will not light.

During installation, do not bend a tape with a small radius to break (this will damage the tracks). If it is necessary to bend the tape at an acute or right angle, make its cut, then the parts are connected by means of connectors.

In order for the tape to serve for a long time, when it is connected, they provide a heat sink, fixing the backlight in those places where there is no heating of the bases.

To connect, you need power supplies with a power reserve of 20-30%. In this case, you can connect not only one, but also several tapes. Do this with respect to the polarity.

After taking measurements and cutting the tape, the strip is built up. It is connected by means of special clips.Then the tape is attached, the free contacts are connected to the controller.

How to make a diffuser for an LED strip?

The diffuser can be made with your own hands from acrylic and plexiglass. They are transparent, inert to mechanical stress. You can also use polycarbonate and polystyrene.

The profile can be a regular plastic box, which is used when laying wires in a pipe. The profile is angular, U-shaped, C-shaped.

To make the diffuser, take one of the materials and a profile (plastic is suitable for wiring). Surface matting is done according to one of the following schemes:

- by means of a paste that destroys the crystalline structure of the material;

- by abrading the material (for example, coarse and fine sandpaper).

The chemical method requires utmost care... The substance is applied to one side of the material. It penetrates to a certain depth, evenly matting the surface. This technique is good for glass processing.

When working with polycarbonate or acrylic glass, use fine-grained sandpaper. Both materials lend themselves well to this matting.

After the profile is selected, the specified length is cut, the diffuser is cut to size. It is matted, holes are drilled in the box for fasteners.

LED strip with soldered or legally connected wiring is glued to the base of the profile. The profile is attached to its destination, covering the top with a matte diffuser. It is glued or screwed to the previously drilled holes.

For information on how to make a diffuser for an LED strip, see the next video.

The comment was sent successfully.