What can be made from LED strip?

LED strip is a versatile lighting fixture.

It can be glued into any transparent body, turning the latter into an independent lamp. This allows you to get rid of spending on ready-made lighting fixtures, without losing anything in the interior of the house.

How to make a lamp?

It's easy to assemble a lamp with your own hands, having only an LED strip and a suitable body at hand. You will need any white or transparent (matte) box, neat in shape.

Ceiling

For a ceiling lamp, for example, a liter plastic or glass jar (new, without noticeable scratches) from under the chocolate paste may be suitable. Do the following.

- Carefully remove the label from the jar. If it breaks, clean it off with nails or a piece of wood, not metal objects, otherwise the jar will be scratched and it will have to be sanded (matte, diffusing effect). Wash it and the lid. There should be no product residues inside. Dry the jar and lid.

- Cut one or two segments from the LED strip. On a tape powered by 12 volts DC (not 220 V AC), each piece is a sector with three LEDs connected in series. For a small margin of voltage, the tape has a current-limiting resistor or an additional simple diode that removes a few tenths of a volt.

- Using hot glue or sealant, glue a piece of plastic box that is used for cables to the inside of the cover, covered with its own longitudinal cover. It will create an additional base for the ribbon.

- Make two through holes in the lid of the box, the lid of the can and in the box itself. They should be located in the same area and threaded straight, without retreating anywhere or folding when passing through the layers of plastic from which the box piece and the lid are made. To prevent the product from cracking, holes can be made either with a drill with a drill with a diameter of 2-3 mm, or with a hot wire of the same diameter.

- Pull the wires through these holes, after opening the box on the lid. For greater stability - so that the wires do not pull out - you can tie each of them in a box with a simple knot. Through the lid of the box, the wires rush without these knots. Close the lid on the piece of the box.

- Glue the pieces of LED strip to the cover of the box, making sure that the wires stay out of the way. So that they are not visible and do not attract attention, it is advisable to use white wires.

- Solder the wires to the plus and minus terminals. They are pre-bent, pressed so that they do not protrude and do not damage the leads on the tape, since it is a high-tech and at the same time fragile and elastic product.

- Connect a power adapter with the appropriate output voltage. AC voltage is not used at home - the LEDs will blink at a frequency of 50 hertz, and this strains the eyes during long work. You can use a high frequency power supply - 60 Hz or more. So, in fluorescent lamps-"spirals", produced up to the end of the 2000s, a frequency converter from 50 to 150 Hz was used. Observe the voltage and polarity when connecting the power source - turning it on "backwards" will lead to the fact that the tape does not light up, and if the voltage is exceeded, it will fail.

After confirming that the assembled lamp works, hang it from the ceiling. For a more sophisticated look, a loop suspension is glued to the lid from the outside, and the lamp itself can be hung on a homemade chain of steel wire, then painting this chain, or use a decorative ribbon or twine. The wires are carefully threaded through the links of the chain or tied to a string. The end of the string is tied with a beautiful bow on the suspension of the lamp itself and on the suspension of the ceiling.

If you use colored LEDs, then the lamp will become decorative from a simple lamp. Red, yellow, green and blue can add a party atmosphere to lighting in a room. Connect the luminaire to the power supply, install and connect the switch to the circuit.

Wall

Several of these cans can be used for a wall light. It is desirable to fix them on a special suspension or in a row. Use the above technology for assembling the ceiling light. To make a suspension, you will need strip steel - it can be cut from a professional pipe, for example, 20 * 20 or 20 * 40, or you can buy a ready-made sheet for cut strips.

The thickness of the steel should not exceed 3 mm - a thicker one will give the whole structure a solid weight.

Follow the steps below to assemble the gimbal.

- Dissolve the profiled pipe or sheet into strips.

- Cut a small piece from the strip, for example, 30 cm long. Bend it twice - a few centimeters from the ends. You will get a U-shaped part.

- Bend one of the ends by 1-2 cm. Attach to it a lamp (without a suspension loop), made according to the previous instructions, on bolted joints, removing the shade (the jar itself) from the base (lid).

- Drill two holes in the wall for dowels with a diameter of 6 mm, insert them into the wall.

- Mark and drill a hole in the luminaire holder - at the same distance from each other - in the part of the holder that attaches to the wall. Self-tapping screws with a diameter of 4 mm are suitable for 6 mm dowels (cross section with a screw groove). Screw these screws together with the holder into the wall. Make sure the structure is firmly attached to the wall and does not play.

- The wires can be attached to the holder itself. In the simplest case, plastic ties are used. By color, they are selected so that they are not noticeable.

Route the wire with the switch to a place convenient for you. Connect the light to the power adapter.

Desktop

A wall lamp can be easily converted into a table lamp if you do the following.

- Hang a reflector on the body (plafond) of the luminaire. It can be made from sheet steel and coated with silver paint (made from aluminum powder and waterproof varnish). If there is no silver, then it can be bent from a metallized 1-liter milk bag cut at the seams - the inner surface of the cardboard from which such a bag is fabricated is metallized.

- After attaching the reflector, the luminaire is hung either above the table - on the wall, or attached to the table using a piece of reinforcement or a longer strip with a thickness of at least 3 mm.

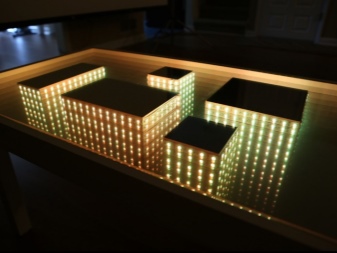

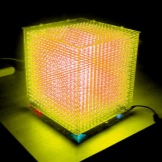

Making luminous figures

To make, for example, a light cube, use a transparent, matte or white material. Plexiglas, white plastic (polystyrene, polystyrene under a layer of plexiglass) will work well to create a dimly glowing figure. If you own the techniques of casting plastic, for example, from bottles, then you will need a furnace with a low (up to 250 degrees) temperature, allowing you to soften and melt the plastic. Aerobatics here is a plastic blower, through which you can blow any figure out of a melted, syrupy consistency of plastic.

In the latter case, work is carried out only in the open air.

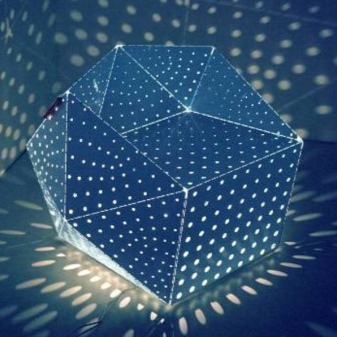

The simplest figures that do not have curvature of faces - tetrahedron, cube, octahedron, dodecahedron, icosahedron - are made without melting plastic, that is, by bonding (for example, gluing) identical pieces of plastic or glass to each other to form a closed space. In the course of action - or at the very beginning - segments of the diode tape are glued to some faces. If the cluster of the tape is the only one, then it can be glued to the last face of the polyhedron - positioned so that the LEDs of this sector shine in the center of space, in the middle.

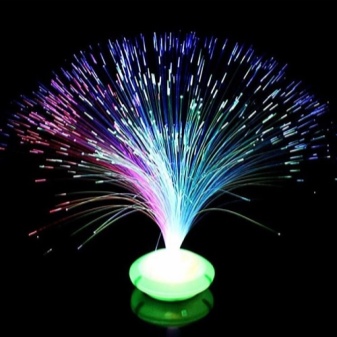

Having made the conclusions of the wires through which the supply voltage is supplied, the polyhedron is collected and closed. The figure can, like simple lamps, be placed on the table, under the bed, placed against the wall (on the upper cabinet), or hung in the center of the ceiling. Several multi-colored figures, controlled by a dimmer, create a dynamic light - just like in a disco. Light cubes and light polyhedrons, along with “broom” lamps containing decorative fiber, are in the greatest demand among young people and connoisseurs of various lighting technology.

Other interior decor ideas

"Advanced" craftsmen do not stop there. LED strips and garlands are not purchased, but are assembled from ordinary super-bright LEDs ordered in China with a supply voltage of 2.2 (color, monochrome) or 3 volts (white of various shades).

With thin wires at hand, for example, from a signal cable, you can create a row in a transparent (inner diameter up to 8 mm) hose, transparent gel pen body, and so on. Lamps, for which a "springy" cord from a home telephone or payphone can serve as a wire, look original - they can be hung like candles at any height or even create a "multi-candle" chandelier. In the latter case, either a frame from an old chandelier is used, in which the socle lamp holders are out of order or "native" electronics burned out, or such a frame (frame) is made independently - from steel strips, professional pipes and studs with nuts and washers.

You can find out how to make a 3D LED lamp from an LED strip with your own hands from the video below.

The comment was sent successfully.