Everything you need to know about drills

A drill is an easy-to-use construction tool designed to create round holes. There are many types of drills that are used to work on a wide variety of surfaces. They differ from each other in the diameter of the device, the type of shank, and the working material.

What it is?

As mentioned above, a drill is a locksmith's cutting device necessary to obtain holes of a circular configuration. The most popular at present are electric drills, screwdrivers, hammer drills, in which metal drills are installed.

Each of these devices performs its own function, but none of them works without a drill that needs periodic replacement. It is very important to understand the variety of consumables for electrical tools.

Description of species

There are several classifications of drills. Depending on the purpose, the tool can be used to process:

- metal;

- ceramics;

- glass;

- tiles;

- wood;

- Chipboard;

- plastic;

- bricks;

- concrete;

- paper (hollow drill);

- multiple materials (combined).

When selecting the correct consumable, consider the coating on the tip. On sale you can find tools with the following types of coating:

- titanium;

- diamond;

- cobalt.

Each of these types of spraying is designed to handle specific materials. For example, diamond is used when drilling glass, cobalt is perfect if you need to work a lot with a drill without changing parts. It wears out less than other analogues.

The titanium drill is very hard and ideal for drilling round holes in metal.

Drills for processing, depending on the shape, are divided into the following varieties:

- spiral (right or left rotation, sometimes they are called reverse drills, side drills);

- stepped (stepped);

- conical;

- crown;

- case;

- circular;

- ring.

The slotted shank drill is used to drill large holes in a variety of materials. It can be cast iron, metal, plastic, steel. Grooved tools can be of different diameters. The most common tooling is 12-20 mm wide.

Replaceable insert consumables belong to the new generation of cutting tools. As the name implies, cutting inserts are replaceable and come in different modifications. They are attached to the steel body with a screw.

Drill performance is increased by quality centering and countersinking, thus reducing the number of work shifts.

Impact cutting tools are used as attachments for heavy-duty rotary hammers or industrial drills. They are better for processing concrete walls. They transmit less vibration for high quality work. Any type of drill with a large tip diameter can be used to enlarge the holes. If you need to drill to a certain depth in order not to make mistakes, use a depth gauge. Outwardly, it looks like a ring of different diameters.

In order for buyers to better understand the intended purpose of a particular tool, manufacturers have come up with labeling. Special letters and numbers are applied to the drills, which indicate what kind of metal the equipment is suitable for processing.

Marking can be in English and Russian, depending on the country of production. With the help of special tables and the number indicated on the drill, you can independently determine the specification of the tool.

Some cutting tools are only used on an industrial scale.

- Cup drill. Used as a cutter attachment. It is indispensable when you need to drill a joint in furniture structures.

- Rail drilling equipment. Such tools are used not only for processing railway rails, but also for working with cast iron, nickel, copper and other rarer metals than steel.

- Pilot drill. Useful when working with wood.

- Double sided and double drills. Used for working with bodies, metal parts and rivets.

- Flexible will help in pulling the cable.

- Drills for filler machines. They are used in the furniture industry, if you need to drill a hole in chipboard, plywood or natural wood.

Some consumable tools are used only for work under the bat. When they talk about rigs of this type, they mean drills for a screwdriver. They are sold in sets. Blind drills are suitable for drilling holes in boxes, and threaded drills for cutting threads at home.

For metal

From time to time, when carrying out repair work, building buildings in the country, repairing equipment or other purposes, you must use a drill that can make a hole in the metal. To do this, you need to buy a special drill. It is sold individually or comes in a set. If the set of drills is not useful to you, then you need to learn how to choose the right consumable.

To be able to distinguish a durable tool from a disposable one, you need to know what elements the drill consists of.

- Main or cutting part most of all involved in metal cutting. It has two edges connected to each other at the core. Smoothly thickens towards the beginning of the shank.

- The shank performs the function fastening a consumable element to construction equipment (drills, screwdriver, hammer drill).

- Working surface. Its main and only function is to remove chips from the drilling site.

When processing a metal surface, any type of consumable tool can be used. The most common are twist drills. They are most often used specifically for metals. On a cylindrical rod with one or two grooves, chips are removed from the drilling site of the desired hole.

Twist drills, in turn, can be classified into several more groups.

- Consumables of a cylindrical shape. Such elements are suitable for working with strong metals, therefore they are made from special combined alloys, where cobalt, tungsten or molybdenum can be added. They can be long, short or medium in size. This parameter is regulated by the corresponding GOSTs. A short drill can be called a drill with a length of 20 to 133 mm, a long one - from 56 to 254 mm, a medium size - from 19 to 205 mm.

- High precision tools - these are always twist drills that comply with GOST 2034-80. They are made of high-speed steel with a thickness of 0.25-80 mm and are intended for processing steel structures with a hardness of up to 229 HB, in some cases - up to 321 HB. Drills with A1 accuracy or, in other words, increased accuracy, are designed for drilling holes from 10 to 13 grades.

- Left hand drills useful if you need to drill out broken bolts or self-tapping screws, and they are also used on semi-automatic lathes that rotate to the left, unlike home rotary hammers or drills.

Tapered tools are suitable for thin metal surfaces. Such consumables can also expand existing holes. They are, accordingly, cone-shaped. With their help, you can get holes of different sizes.Another type of drill that is suitable for working with metal is the core drill. They remove the steel around the periphery of the hole, leaving it in the center. Ideal attachment for a hammer drill when a large diameter hole is required.

The types of drills listed above are ideal for machining steel surfaces of different strengths. The main thing when choosing is to stop your attention on a consumable that will drill the diameter you need in the metal.

By wood

When working with wood with a universal drill or tool designed for working with steel, you cannot get a hole with even edges. Special tools are suitable for this purpose. First, let's talk about twist drills, which are also used in steel processing, but differ in the design of the tip. Outwardly, it looks like a trident, due to which it allows you to make deep holes of small sizes in the range of 2-30 mm.

If you need to make a deep hole, then be prepared for the fact that the groove is clogged with chips. The disadvantage of spiral tools is also the rapid failure of the side edges. This can happen when the drill hits a nail or screw. Also, when it is necessary to process wood, you can turn your attention to twist drills. They come in all kinds of sizes and diameters and will become indispensable when you need to drill a through hole, connect thick beams or thin boards.

The formwork drill is suitable for processing softwood or medium-hard boards. The steel barrel is designed for continuous operation. These cordless or cordless drill accessories are designed with beveled cutting edges to minimize the likelihood of nail breakage. When assembling furniture or building structures, always use screwdrivers or other tools of this type.

For chipboard, a special through drill with a soldered plate or a monolithic one is suitable, which is used when processing tile materials, including for plywood. The high strength body is made of special steel - this guarantees increased wear resistance.

Pay attention to the black or orange protective coating on the tip of the drill - it protects the tool from the accumulation of dirt and increases its service life.

Over stone and brick

A stone drill must be included in a set of consumables designed for a wide range of repair work of varying complexity. You can't do without a brick drill if you need to make a hole in the wall of the apartment. Equipment for working with a stone comes in several sizes:

- large diameter tools from 4 to 22 mm, no more than 600 mm long;

- medium drills with a diameter of 4-16 mm;

- small consumables ranging in size from 3 to 9 mm.

A hammer drill is ideal for drilling concrete walls, thick bricks, in some cases it can be replaced with a drill. A drill for granite, brick or stone is used for installation work. It has high strength, so it will not break even during long-term drilling.

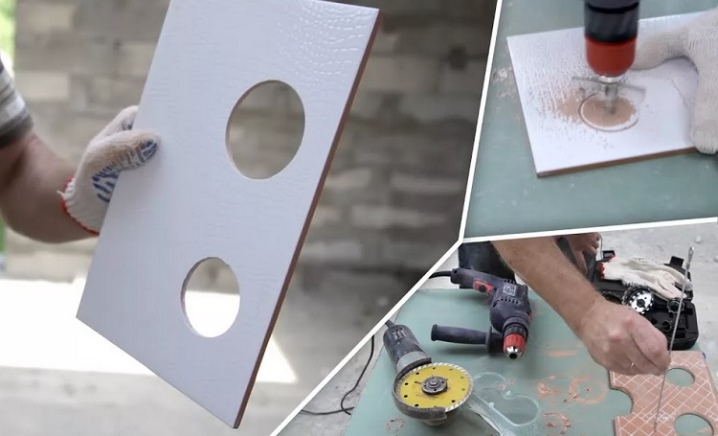

Glass and tile

A drill for glass, ceramics or tiles is harder to pick up than a tool for working with metals. This is due to the fact that glass is a more delicate material to handle, and you need to be able, together with consumables, to correctly select the main tool for processing it. Low-speed drills, low-speed and cordless screwdrivers are ideal for working with ceramic tiles and glass.

Low-speed screwdrivers (power up to 1000 rpm) with limited screwing depth are divided into devices with low, medium, high spindle rotation speed. They are designed for use with diamond tipped drills. Such devices are suitable for drilling glass materials. The glass tooling is tubular in order to drill the required hole as accurately as possible.There are no spiral chip flutes in this type of tool. Core drills are more suitable not for glass, but for tiles. With such equipment, you can easily drill a large hole.

Materials (edit)

In addition to the metal drills we are used to, cutting tools made of carbide materials, namely tungsten carbide, are on sale. With such cutting tools, it will not be difficult to process aluminum, plastic, textolite. The carbide-tungsten alloy is used to produce the cutting part with a hardness of HRC 50, and the drill shank is made of steel. If there is a tungsten carbide drill in the drill, then you can safely make a hole in stone, porcelain, ceramics, aluminum.

Another type of drills is ebonite. As such, they do not exist. On sale you can find a drill with a victorious tip, which is equipped with a carbide plate. It is with this material that ebonite is confused.

Coating options

Regardless of what material the drills were made of, they tend to wear out. To increase the service life, manufacturers came up with the idea of treating products with different coatings, each of which endows the drill with additional characteristics. The simplest material used for drills is an oxide film. It is effective in protecting the handpiece from overheating during intensive work.

The titanium coating protects the base from corrosion and abrasion. These rigs are yellow, more expensive than black, but cheaper than consumable tools with a cobalt coating. Titanium increases the service life of the consumable by at least 3 times. It is used when working with alloy steel grades. Also, such a cutting tool is suitable for drilling holes in high viscosity alloys. If the alloy from which the tool is made indicates that it contains about 5% cobalt, then this will provide high heat resistance to metal.

Also worth mentioning is the diamond-coated tooling. These tools are suitable for working with glass and ceramics.

Size and weight

The most common are twist drills. They have a universal purpose. The standard diameters of these drills are in the range of 1-31.5 mm. As you can see, the difference between the starting and ending numbers is quite large. This speaks of a wide range of consumable tools. Snap-in options can vary significantly depending on the intended use. Cutting tools for metal in diameter do not exceed 12 mm, and their length is not more than 155 mm. If the equipment has a tapered tail, then the parameters of the working tool will be 6-60 mm in width and 19-420 mm in length. Wood drills have the following geometric parameters:

- large - from 5 to 11 mm with a cutting edge from 1.5 to 2 mm;

- medium - width 10-20 mm, edge - 2-4 mm;

- small - from 20 to 50 mm in diameter, with an edge of 6-8 mm, such equipment can also be called a thin consumable tool.

There are also micro drills that are used for engraving. All sizes of cutting tools are regulated by a number of GOSTs.

Accuracy classes

There are only two types of drill precision - class A and class B. The first option is consumable items of increased accuracy for drilling holes of 11-14 grades. This unit of measure determines how accurately the product or its elements are manufactured. Tooling with precision A is manufactured with a ground profile. Due to this, such drills have a lighter chip output, and the heating temperature is lower, and the tool life of the cutting part is much higher.

The holes themselves, obtained with drills of increased accuracy, have a higher quality of the machined surface. Class B or B1 is a longitudinal screw, the sharpening angle is 118 degrees. These are versatile drills that are suitable for industrial and domestic purposes.The first option is almost half the price, because such consumables are used to work on machine tools.

Popular manufacturers

The market for construction tools and consumables offers a wide selection of products in different price segments. Many buyers consider the German company Metabo to be the best brand, which offers modern innovative solutions suitable for both high-level professionals and ordinary owners who purchase tools for home use. Particularly attractive is the wide assortment of drills. They manufacture tooling for working with metal, wood, glass, ceramics, concrete, etc.

The next company to which you should pay attention is the domestic enterprise "Interskol". It has long been the most influential on the Russian market and can compete on a par with more well-known foreign brands.

In addition to these two giants, a number of other companies can be distinguished that produce drills and other consumables in different price segments, for example:

- Mastertool;

- Housetools;

- "Zenith";

- "Attack";

- DIAGER and many others.

In any case, when choosing, you need to focus on the technical characteristics and reviews about the tool itself, and only then look at the manufacturer. This is the only way to find good accessories for drills and screwdrivers.

How to choose?

The easiest way to choose a consumable tool is based on what material you need to process. It can be wood, concrete, steel, glass. Each type of drill is designed to create holes of different diameters and depths. Be sure to take into account the strength class - then you will not need to put much effort during work, and the equipment itself will last much longer.

Always ask about the technical characteristics of the product, consider the following parameters:

- drill sharpening angle;

- tool length;

- the thickness of the consumable;

- accuracy class;

- snap shape.

For example, for drywall, only core drills are suitable. They can be sharpened on their own, they have a complex design and a slightly higher price than simple cylindrical consumables. For deep drilling, tooling with carbide inserts with a machining range of 8 to 65 mm is suitable. They must be spiral or feather. These consumable tools can help you create a deep hole effortlessly.

Chamfering or deburring is quite common when machining different surfaces. These operations are performed using a large number of drills. Recommends choosing solid carbide tools for chamfering.

If you find it difficult to find a quality drill for your tool, we suggest buying special sets containing different types of drilling and percussion equipment.

For information on how to make a simple drill stand with your own hands in an hour, see the next video.

The comment was sent successfully.