Hex shank drills: features and selection rules

We can safely say that no repair is complete without a tool such as a drill. As a rule, drill owners also purchase drills. And more often than not one, but whole sets. Hex shank drills are one of the versatile models. Read about why they are convenient to use, how to choose them, what are their advantages, read this article.

Characteristic

Hex shank drills are versatile auxiliary tools, which is not only applicable for drilling a variety of materials, but also perfectly matches a large number of different drills, also used in conjunction with screwdrivers and hammer drills. These drills are metal products with a hexagonal tip (shank). Easy to use - if necessary, they can be easily and quickly removed from the mount.

The product is attached to the drill with a chuck. The latter firmly squeezes it, not allowing the product to escape. Some hammer drills are equipped with holders instead of chucks, where the hex drill can be firmly fixed, unlike the model, for example, with a round shank.

Other important advantages of using such "hexagons" can be noted.

- The products are easily and firmly attached to conventional electric drills.

- They can be used in conjunction with screwdrivers (only if the latter have a hexagonal holder).

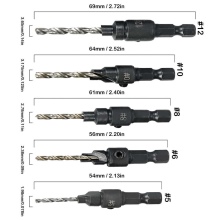

- The presence of holders of the same size for all hex drills, regardless of their length, diameter, thickness. Tool holder length 33.32 mm, width 6.3 mm between parallel sides. The standard sizes help to firmly attach them to a variety of devices.

- The ability to quickly replace one product with another hex.

Other features of such a hexagonal product include increased runout when operating at high speeds. The reason is the lack of a rigid attachment of the drill and power tool. And you also need to know that drills with a hexagonal holder cannot ensure the accuracy of drilling.

In this regard, the models on cartridges have proven themselves in a much better way.

Types

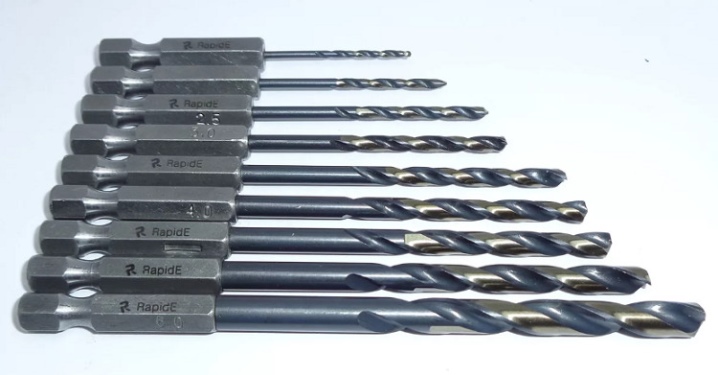

Nowadays there are many manufacturers who produce hex drill sets of various lengths and diameters.

The modern assortment of such products is a number of models for processing various materials - ceramic surfaces, concrete walls, products and structures made of metals and their alloys, wood, plastic products, tile surfaces and others.

Hexagonal drills are also classified according to their design - they can be produced with different structures of grooves and sharpening angles. There are several types.

- Twist drills. The simplest and most popular models. They are drills with two cutting edges and two flutes for chip evacuation.

- Cone models... The tip of such a product has the shape of a cone. Such models are rarely used and only for special machines.

- There are also screw, feather, milling models., as well as products with Lewis and Forstner spirals.

Drills can be made from various metals and alloys. Manufacturing and processing technology can also affect the performance of tooling (drills).

Drills can be conditionally divided depending on the country of origin (China, Europe, and so on). Information on this is provided by the marking on the shank.Quite often, brands produce sets of drills of the same diameter, but of different lengths, as well as sets of drills of the same length, but with different diameters.

All drills are also distinguished by color. The color of the product indicates the processing method and the material of manufacture of the product.

- Gray... The cheapest and most popular. They do not differ in persistence.

- Black... They were treated with superheated steam. Suitable for drilling in carbon steels and non-ferrous metals.

- Slightly golden. They have been hardened and will last a long time.

- Golden. They are coated with titanium nitride and are of the highest quality, durable and reliable.

Departing from the topic, it should be noted separately that similar drills are made for the screwdriver. Screwdrivers are most often not designed for a hexagon and require a certain type of shank. In addition to hex, there are triangular, cylindrical, conical, hex (hexagonal) and other types of shanks.

Choice

Before each session of work, it is important to remember that each type of drill requires the selection of a certain mode - the number of revolutions. This is how you can improve the quality of your work and reduce the risk of hitting the drill.

A number of factors can be noted that should be followed when choosing a particular product.

- Dimensions (edit)... It is not always necessary to buy whole sets of drills. In total, there are three conventional size divisions - short (length from 20 to 131 mm), elongated (from 132 to 205 mm), long (from 206 to 254 mm).

It is necessary to purchase and select models depending on the dimensions of the workpiece and holes.

- When choosing drills, you also need to pay attention to the marking. All products with a diameter of more than 2 millimeters have it. If the section diameter is greater than this value, then the value of the cross section is applied, as well as the steel grade. The manufacturer's logo is also applied to products with a diameter exceeding 3 mm. The most common letters are "M", "P" and "K", which denote the content of molybdenum, tungsten and cobalt. Next to these letters there are also numbers that reflect the percentage of these metals in the product. And you can also find the markings HSS-TiN and HSS-TiAN, which indicate the presence of a titanium coating on such products.

Simply put, these are the toughest drills that can be used to drill titanium-containing metals.

The choice of drills for woodcarving is relatively simple. Wood is not as durable material as metal, so the probability of chipping off the edges of such products is reduced to zero.

Drills for woodcarving are also less expensive than models for metal.

You can find out how to repair a broken hex shank drill in the video below.

The comment was sent successfully.