Everything You Need to Know About Wood Drills

The pen drill, with which you can make a hole of a given diameter, is one of the most sought-after tools that are popular with joiners, carpenters and other craftsmen working with various types of materials. The drill has a high productivity ratio and allows you to quickly make round holes of various diameters in the workpiece being machined. Work can be performed not only on wooden parts, but also used for processing drywall, various plastics, MDF and chipboard. By its structure, the pen-type drilling tool has an elongated body in the form of a rod, at the end of which there is a cutting extended tip and a small cone-shaped protrusion.

Peculiarities

The wood drill bit consists of a working body and a tail section. The drilling process is performed by the working part, which looks like a flat, but sharply sharpened small blade. At the end of the blade, strictly in the center, there is a small cone-shaped protrusion, which is used to mark the center of the future hole in the workpiece material. The extended blades of the pen tool have sharpened edges located on both sides of the tool, relative to the tapered ledge.

Sides-blades are sharpened at an angle, the inclination of which is made to the right.

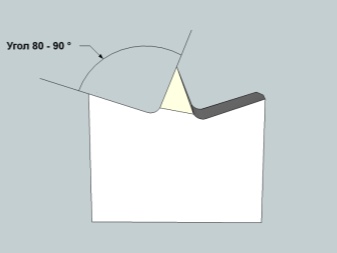

Pen tools for drilling can be made with one working side or with two cutting surfaces. A single-sided pen drill cuts a 75-90 ° cut angle on the workpiece material, while a double-sided tool model cuts at a 125-135 ° angle.

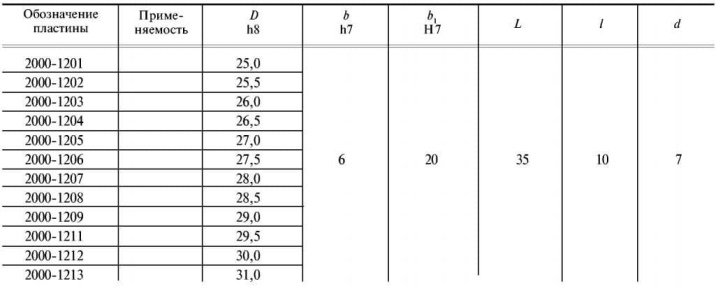

In the production of pen drills, manufacturing plants adhere to verified proportions laid down between the width of the working blade and its thickness. For example, for a tool with a diameter of 5 to 10 mm, the thickness of the working part will be from 1 to 2 mm. Drills with a diameter of 10 to 20 mm have a working part thickness of 2 to 4 mm. If the pen drill has a diameter greater than 20 mm, the blade thickness will be 6 to 8 mm.

Dimensions (edit)

With the help of a pen drill, holes with a diameter in the range of 5-60 mm can be made. To perform specific types of work, craftsmen choose a certain size of the drill, but if necessary, you can purchase a set of tools with the most demanded diameters - 25 and 35 mm, as well as 40, 50 and 60 mm. Such parameters are most often in demand for solving various problems related to woodworking, as well as in the manufacture of furniture or other joinery products. If the hole that needs to be made is of a larger diameter than 60 mm, then you will need to use another type of cutting tool - a circular crown, since the core drill in this case will not be able to process an area larger than its diameter.

The size of the pen tool for drilling in length is 150 mm, and at its end opposite the working part, there is a processing of the rod-body in the form of a hexagon.

This makes it possible to fix the drill inside the chuck of a screwdriver or drill, as well as use special hex adapters to perform an adjustable drill extension. Despite the simplicity of its design, the pen drilling tool has many positive qualities and does an excellent job with the task assigned to it.

Processing options

When choosing a drill for making large-diameter holes, professional carpenters and those who like to make wood products with their own hands are guided by what type of hole they need to make. Holes in wood or plastic blanks are of the following types.

- End-to-end - that is, the hole goes through the entire thickness of the workpiece material. Various threaded elements are inserted into such holes. These can be studs, bolts. In addition, without making a through-hole type, it is impossible to install door handles or locks. In addition, through perforation is widely used in the production of furniture structures.

- Deaf - the hole passes only through a certain depth in the material, without having an exit from the reverse side of the workpiece. Blind holes are made for mounting door hinges or are used on furniture products to mount an internal door opening-closing system, as well as to install handles or locks.

In some cases, a pen drill is a substitute for a disk cutter, which is also used to make holes of large and small diameters, but, unlike a drill, it costs several orders of magnitude more.

If the work is one-time, and the drill diameter fits the required hole diameter, it makes no sense to purchase expensive equipment, since you can get out of the situation by using an affordable pen tool for drilling.

The pen drill is suitable for both electric drills and cordless screwdrivers by simply attaching to the chuck of these tools.

Selection Tips

In modern hardware stores, there is a huge selection of pen drill models, which differ in the manufacturer's brand and cost, depending on the quality of the product. When choosing this tool, you need to pay attention to the following most important parameters.

- Proportionality of form - there are two sharpened blades on the working part of the drill relative to the central tapered ledge. Both parts of the product must be symmetrical and sharpened at the same angle. It will not be superfluous to check the compliance of the tool with the drill diameter indicated on the package, this is especially true for Chinese-made products.

- Sharpening quality - the working part of the cutting blades of the drill must be well sharpened, free from chipping, chipping and meet technical standards. The drill is sharpened automatically in production and looks perfectly flat.

- Defects - the purchased tool should be carefully examined for hidden flaws, which can be both on the working surface of the product and on its rod body. The drill, made in the factory, has no deformation, scratches, chips, scuffs and traces of rust.

In order not to be mistaken with the choice of a pen tool for drilling and to purchase a really high-quality and reliable product, experts advise paying attention to the color of the metal it consists of. The metal of the most durable drill has a deep dark color, which is acquired by the material in the process of processing its surface with hot steam.

This kind of hardening strengthens the steel alloy and makes it more resistant to mechanical stress.

If the drill has a steel dark silver shade, this indicates that the tool has not been subjected to additional processing, which means that it is less protected from mechanical stress, and its hardness is lower than that of a dark-colored analog.

Some pen drills have a distinct gold color and a shiny surface. Having seen such a tool, you should know that the manufacturer has treated its surface with a titanium nitride coating. This coating significantly extends the service life of the drill, maintaining its cutting properties during operation, and titanium also protects the surface of the drill from mechanical damage. With a titanium pen drill, you can work with particularly durable materials by making holes of a given diameter in them, while the drill does not have to be regularly adjusted or sharpened - this will need to be done much less often than on conventional pen drills made of uncoated steel alloys.

Operating rules

To obtain the greatest efficiency when performing work with a perforated drill, as well as to extend the period of their operation, the following rules must be observed.

- Work on drilling holes in wooden surfaces should be carried out at low drill speeds, with an indicator of no more than 300-450 rpm. The rule should be observed - the thicker the drill diameter, the lower its rotation speed should be. This approach allows for better results and keeps the drill from deforming.

- To perform work with a pen drill, an electric drill is most suitable, which has the ability to adjust its power, while a screwdriver cannot always give the desired force and rotation speed for the drill.

- If the standard length of the drill is clearly not enough to make a hole in hard-to-reach places, it is required to use a specially designed adapter for this, which is fixed in the chuck of the electric drill.

- Before starting the drilling work, the section of the working surface of the workpiece is carefully measured and the place of work of the drill is outlined, that is, the point where its cone-shaped protrusion will be installed - this will be the center of the circle to be performed when the tool is operating. Further, the drill must be installed relative to the working plane, only maintaining an angle of 90 °.

- It is recommended to start the drilling process at low speeds of the electric drill, gradually adding them as the drill goes deeper into the workpiece material. Adding RPM to the drill will help the drill go through the material more easily and protect the drill motor from overheating. When you notice that the core drill has reached the required depth within the workpiece material, the drilling process must be stopped.

After the hole in the workpiece is made, inside its niche, if it is not through, a lot of waste material will be collected in the form of shavings.

They need to be removed, and this is best done not only at the end of the full cycle of work, but also during their execution - as soon as you notice that a lot of chips have accumulated.

To do this, the drilling is stopped, the shavings are removed from the hole, and then the drill is again immersed in the formed recess and continues to drill to the required depth level.

How to sharpen?

Like any working drill, a pen tool needs to be sharpened from time to time, since in the process of drilling the blades at the working part of this product become significantly dull and can no longer make accurate holes. This can be done without resorting to the use of complex technologies - sharpening a drill in the form of a feather is performed with an ordinary flat file or a small machine with an emery wheel is used. In the process of turning a tool, it is important to maintain the angle of the cutting blade, as well as the shape of the cutters of the working part of the drill. In addition, it is important to keep the tapered protrusion strictly centered on the tool.

The fact is that any deviation of the tapered part is inevitable during the execution of work will lead to the fact that the centering of the hole made by such a drill will be violated.

If in the process of work the pen tool for drilling was strongly deformed, then you will not be able to completely restore its geometric proportions without special equipment.Therefore, the time and effort put into the process, if you edit the drill by hand, will not pay off - such a tool is no longer suitable for work, it will have to be thrown away. The cost of a pen drill is not so high, so the easiest way in such a situation is to purchase a new product for yourself.

For an overview of the Irwin Blue Groove brand, see below.

The comment was sent successfully.