How do drills differ from drills?

In order to make a hole in the wall of the required length and diameter, you will need not only a special construction tool, but also drills or drills. If in the process of work the question arises of what is best to use, it is necessary to find out the main differences between drills and drills. Only then can you make the right choice.

Description

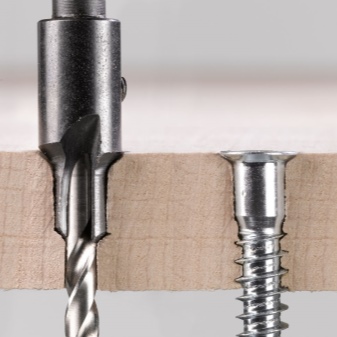

A drill is a specific cutting tool, the main purpose of which is to make blind or through holes of various diameters on the surface. Also, with their help, you can carry out a reaming procedure, which implies an increase in the diameter of already existing holes. Drills differ among themselves not only in size, but also in purpose. For example, they can be designed to work with wood, plastic, metal, concrete and some other surfaces. But at the same time any drill consists of the following parts:

- in the front there is a cutting cone with very sharp edges;

- in the center are spiral grooves designed to eject chips from the cavity of the hole;

- at the end there is a smooth cylindrical tail, it is needed to fix it in the instrument.

If the drill is designed to work with materials such as plastic or wood, it is less durable. For metal or concrete, the drills are stronger.

A drill is also a specific accessory that makes holes in surfaces. It can only be installed in a hammer drill or an impact drill / driver. The drill is suitable for working with hard surfaces: concrete, stone, brick. The accessory consists of several zones:

- smooth tail, for which the part is installed in the chuck of the power tool;

- spiral and a special cavity for dust removal;

- screw rod.

In addition, the use of a drill involves the following types of work: drilling, hammer drilling, chiselling.

The main differences

Despite some similarities, drills and drills differ significantly from each other. The differences are as follows.

- Ponytail type. If we talk about drills, then the part inserted into the chuck is usually of the SDS-Max or SDS-Plus type. In drills, only a cylindrical tail can be observed. Also, the drill has special grooves for secure fixation in the chuck of the power tool.

- Product durability. Since the chiseling method is sometimes used when working with a hammer drill, the drills must also be strong. The drills are less wear-resistant. When performing such work, they will bend or even break.

- Manufacturing material.

- Diameter. Borax is always thicker.

Of course, the differences can be expressed in terms of cost and manufacturer.

What is the best choice?

If a person does not know which accessory is better to choose: a drill or a drill, he initially needs to decide on the type of work to be performed. Start with the material of the surface where you want to drill the hole. If it is plastic or wood, the choice of drill is obvious. In this case, you can take a not particularly durable option. If you need to drill concrete or brick, you should take reliable drills. The diameter is determined according to individual requirements.

Important: experts recommend buying drills not individually, but as a whole set. This is necessary so that accessories of different diameters are always available.

If you need to drill hard surfaces, then the drill must also be strong. These accessories are usually made from high speed steel, alloy steel and carbon steel. This is the most reliable material.During work, it is important to control so that the drill does not overheat. If the surface is very hard, such as concrete or stone, and you need to make a hole in it, it is better to choose a drill. In the process, it is advisable to use a perforator. Anyone who has done such work at least once in his life knows that holes in hard surfaces do not have to be drilled, but drilled.

There is one more rule to be guided by when choosing an accessory. If you need to make a long, but at the same time rather thin hole in the surface, then it is better to choose a drill. But it should be remembered that it must be strong. When using a conventional drill, there is a risk of breaking it. It can get stuck in the surface and take time to remove the remainder. If you need to make a wide, but not very deep hole, then it is better to choose a drill.

When choosing drills and drills for concrete and other materials, you should pay attention to the quality of the product. It is better to buy such things in proven brand stores. Very often, accessories can be bought directly from the places where the equipment itself is sold. It is important to pay attention to the manufacturer. Even if you choose the right tool, but at the same time it will be of questionable quality, you will not be able to make a normal hole.

It is important to take into account the price, read the information on the packaging (it is always available on branded items) and use the purchased accessories solely for their intended purpose.

For information on how drills differ from drills, see the next video.

The comment was sent successfully.