How to choose a drill tap?

Modern developments present on the market more and more new tools that increase productivity and accelerate the pace of production. Combination devices combine two or more operations into one. Among these innovations, there are many cutting tools. In addition to drill taps, there are many other combinations:

- countersink tap;

- tap-tap;

- reamer-tap;

- countersink-reamer-tap.

These types of tools are widely used in mechanical engineering and other industries where complex shapes and threaded holes are required.

What it is?

The drill-tap refers to cutting tools of the combined type. This tool combines 2 types of technological operations into one. Hole drilling and tapping with a tap drill take place at the same time.

It is used when there are no ready-made holes for threading in cast parts, forging, stamping.

Drill-taps in this case save time that will be needed for each operation separately. In mass production, using combined tools, they modernize operational processes, increase productivity, and reduce the time to achieve results. The number of special devices decreases, therefore, the cost of the product decreases.

Views

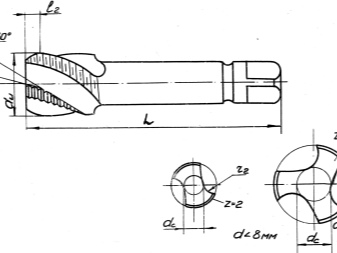

Advanced cutting tools have many combinations and the number continues to grow. Because such a drill is used simultaneously for drilling and tapping, then the fixture consists of 2 parts. The first is the drill, the second is the tap. There are 2 types of these combined instruments.

The type described above is used for drilling holes and obtaining threads with a wide pitch of turns. Such operations are performed on thin metal. In this case, low requirements are imposed on the accuracy of the thread, the holes are made through. In this case, the drill has a length of 2-2.5 diameters of the second stage - the tap.

Another type of combined drill-tap was developed by Riga designers. This type is much stronger than the first type, with more accurate indicators. It cuts threads with a smaller pitch of turns, giving a high quality work. The step of the drill is one and a half times longer than the length of the drilling section, the thread can be made in large and small turns.

The second stage after the drill is made in the form of the same spiral and is supplemented with teeth that cut the metal, acting as a tap. The angled arrangement of the tool strips increases its resistance to overload during operation. In this case, the removal of chips occurs more freely.

The tool requires adherence to high-speed feed conditions, which means a timely reduction in revolutions required for threading.

Significant differences between different types of combination drills lie in the structure of the drill part... This part is carried out in the classic form - a drill with spirals. When the rear part of the auxiliary surface is in the form of a cylinder, the finished hole expands. The tool can be with or without a jumper.

This shape reduces axial loads, thereby increasing tool life. The downside is the difficulty in manufacturing and sharpening.

Another type of drill is the reverse-directed inner taper. This approach helps center the drill during the workflow. After work, the drill leaves a tapered mark, which is then cut off during threading.With shaped drilling, end chamfers of various heights and angles are bored. A clear advantage - you do not have to use an additional tool, waste time on two operations.

The disadvantages are undoubtedly the heavy load on the drill bands and the long operation time.

Such a model is also distinguished by the difficulty of manufacturing due to the complexity of the selection of geometry. Its task is to sharpen chamfers and drill holes.

Manufacturers produce combined drills in split and one-piece versions. Such a tool cuts right and left threads, it is made from various types of metals.

Despite the obvious advantages, the tool has quite significant disadvantages. This is a low quality of the thread with a rigid fixation in the chuck of the machine. Difficulty setting when interacting with metal that is difficult to process - the axial feed must accurately correspond to the pitch of the specified thread.

Criterias of choice

The nominal designations and distances between the mating grooves will help to make the right choice of the diameter of the drill-tap. To determine the size of the hole for the thread, there are special tables with which it is quite easy to choose a tool. The parameters by which the dimensions are determined are the direction of the turns, type, step and shape.

All parameters of dimensions and metric values are regulated by GOST 19257-73. For these calculations, experts use a caliper. In addition to single-piece, there are sets of drill-taps on sale, which is very convenient.

An overview of the tap drill from the Aliexpress website in the video below.

The comment was sent successfully.