Features of dry mix M300

The emergence of new technologies and materials, the purpose of which is to speed up the process and improve the quality of work assessments, pushes construction and installation work to a new level. One of these materials is the dry mix M300, which appeared on the construction market 15 years ago.

Peculiarities

Dry mix M300 (or sand concrete) is produced by mixing several components. Its main composition includes fine and coarse river sand, plasticizing additives and Portland cement. The composition of the M-300 mixture may also contain granite screenings or chips. The proportions of the constituents depend on the purpose for which the product is intended.

Sand concrete M300 is used for pouring the foundation, concreting stairs, paths, floors and outdoor areas.

Specifications

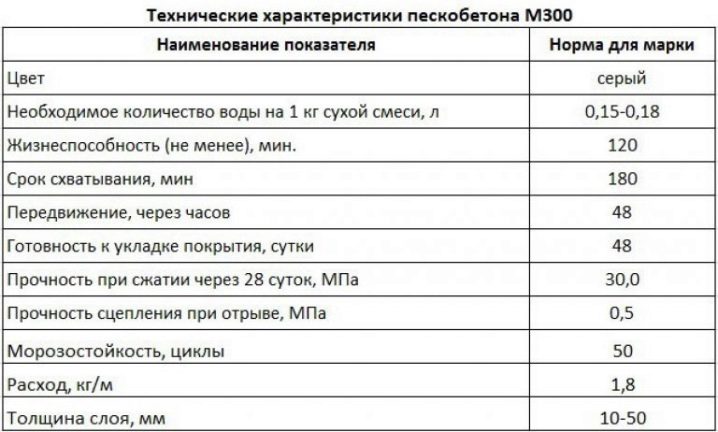

The technical characteristics of sand concrete determine the rules for its operation and resistance to external destructive factors. The composition and technical properties of the M300 mixture make it possible to use it both as a self-leveling mixture (self-leveling mixture) and as a repair compound.

Composition

Any variants of M300 mixes are gray. Its shades can be different depending on the composition. For such materials, Portland cement M500 is used. In addition, the M300 mixture according to GOST has the following proportions of the main components: one third of cement, which is a binding ingredient, and two thirds of sand, which is a filler.

Filling the mixture with coarse sand makes it possible to achieve a harder composition, which is especially appreciated during foundation work.

Frost resistance

This indicator indicates the ability of the material to withstand multiple temperature changes, alternating melting and freezing without severe destruction and decrease in strength. Frost resistance allows the use of M300 sand concrete in unheated places (for example, in capital garages).

Frost resistance of mixtures with special additives can be up to 400 cycles. Frost-resistant repair mixes (MBR) are used for mixing building compounds used in the reconstruction and restoration of concrete, reinforced concrete, stone and other joints, filling voids, cracks, anchors and for other purposes.

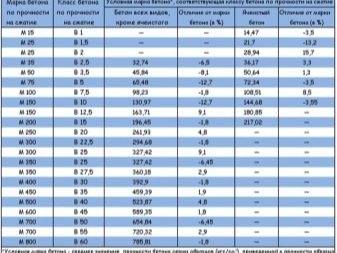

Compressive strength

This indicator helps to understand the ultimate strength of a material under static or dynamic action on it. Exceeding this indicator has a detrimental effect on the material, leading to its deformation.

Dry mix M300 is able to withstand compressive strength up to 30 MPa. In other words, given that 1 MPa is about 10 kg / cm2, the index of compressive strength of M300 is 300 kg / cm2.

Temperature spread

If the thermal regime is observed at the time of the work, the process technology is not violated. The further preservation of all the performance properties of concrete is also guaranteed.

It is recommended to work with sand concrete M300 at temperatures from +5 to +25? С. However, sometimes builders are forced to violate these guidelines.

In such cases, special frost-resistant additives are added to the mixture, which allow work to be carried out at temperatures up to - 15 ° C.

Adhesion

This indicator characterizes the ability of layers and materials to interact with each other.Sand concrete M300 is able to form a reliable adhesion with the main layer, which is equal to 4kg / cm2. This is a very good value for dry mixes. To maximize adhesion, manufacturers give appropriate recommendations for preliminary preparatory work.

Bulk density

This indicator means the density of the material in an unconsolidated form, taking into account not only the volume of particles, but also the space that has arisen between them. This value is often used to calculate other parameters. In bags, dry mix M300 is in bulk with a density of 1500 kg / m3.

If we take this value into account, it is possible to draw up an optimal ratio for construction. For example, with a declared density of 1 ton of material, the volume is 0.67 m3. In non-scale construction work, a 10-liter bucket with a volume of 0.01 m3 and containing about 15 kg of dry mix is taken as a meter for the amount of material.

Sand particle size

Plants produce sand concrete M300 using sand of different fractions. These differences determine the peculiarities of the technique of working with the solution.

There are three main sizes of sand used as raw material for dry mixes.

- Small size (up to 2.0 mm) - suitable for outdoor plastering, leveling joints.

- Medium (0 to 2.2 mm) - used for screeds, tiles and curbs.

- Large size (more than 2.2 mm) - used for pouring foundations and foundations.

Mixture consumption

This indicator characterizes the consumption of material with a layer thickness of 10 mm per 1m2. For sand concrete M300, it usually ranges from 17 to 30 kg per m2. It is worth noting that the lower the consumption, the more economical the work costs will be. In addition, manufacturers often indicate the consumption of sand concrete in m3. In this case, its value will vary from 1.5 to 1.7 t / m3.

Delamination

This indicator characterizes the relationship between the lower and upper parts of the solution. Mix M300 usually has a delamination rate of no more than 5%. This value fully complies with the requirements of the standards.

Manufacturers

Enterprises that manufacture sand concrete M300 in their production use a base similar in composition, adding various additives to it. Filling of dry mixes M300 is carried out, as a rule, in paper bags with or without a polyethylene inner layer. Mainly bags of 25 kg, 40 kg and 50 kg are used. Such packing is convenient for transportation and handling.

Individual bags can be delivered to places where special equipment cannot pass.

"Reference"

The Etalon trade mark produces dry mixes M300 for horizontal surfaces with moderate load. Etalon sand concrete contains two main components: coarse sand (more than 2 mm in size) and cement. The mixture is ideal for screeds and foundations, both as a basic component and as a repair compound. Also sand concrete M300 of the Etalon brand can be used as a mortar for brickwork and for the manufacture of ebbs. This material has high strength and good shrinkage rates, is able to withstand temperature drops from -40 to +65? С.

"Crystal Mountain"

The main raw material for the dry mix MBR M300 of this manufacturer is quartz sand from the Khrustalnaya Gora deposit. The composition also includes Portland cement and a complex set of modifying components. The material is suitable for the production of fine-grained concrete material, which is used for repair and restoration activities, for the restoration of defects in concrete and reinforced concrete structures, technological holes, repair of cracks and many other purposes.

"Stone Flower"

The company "Stone Flower" offers sand concrete M300, intended for floor screed.This product is also used for foundation work, brickwork, building reinforced concrete structural foundations, concreting stairs and much more. Sand concrete M-300 "Stone Flower" consists of a fraction of dry sand and Portland cement. Its solution is very plastic, dries quickly. Also, this mixture is distinguished by good indicators of water resistance, frost resistance and resistance to atmospheric precipitation, which are responsible for maintaining the finished structure in adverse weather conditions.

Application Tips

Most often, the dry mix M300 is used for pouring concrete floors. Such surfaces are ideal for industrial premises, cellars, basements or garages. Before using sand concrete, it is necessary to carry out preparatory work. First, the surface must be treated with a special chemical solution. For highly porous surfaces, it is rational to use moisture protection products.

If you just need to level the surface, a 10 mm layer will be sufficient. If it is necessary to create a more durable layer between the base and the finished floor, its height can be up to 100 mm.

The screed itself in this case is made using a reinforcing mesh.

With the help of dry mix M300, you can level not only floors, but also any other bases. Its application makes it easy to seal the joints between concrete fragments. Also sand concrete M300 perfectly neutralizes the obvious shortcomings of concrete structures.

M300 material has found application in the production of tiles and borders. Garden paths, blind areas, flights of stairs are poured into them. The M300 is also actively used as a masonry mortar when working with bricks.

You will learn how to do the floor screed with your own hands from the video below.

The comment was sent successfully.