Concrete contact: what is it and what is it used for?

In the process of self-repair in an apartment, an unforeseen problem of poor adhesion of finishing materials to the surface on which they are attached may arise. In order not to face these troubles, it is recommended to pre-treat the base coat with concrete contact. To use the composition correctly, it is enough to understand what it is, and most importantly how and for what it is used.

Peculiarities

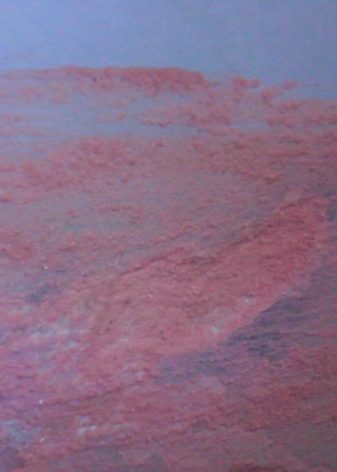

Concrete Contact is a special deep penetration primer mixture based on finely dispersed quartz filler in the form of sand, the particle size of which is 300-600 microns. By including this component in the solution, a strong rough surface is created, on which finishing work can be carried out with absolutely any materials. The concrete contact adheres firmly to the base due to the presence of special polymer adhesives in the composition.

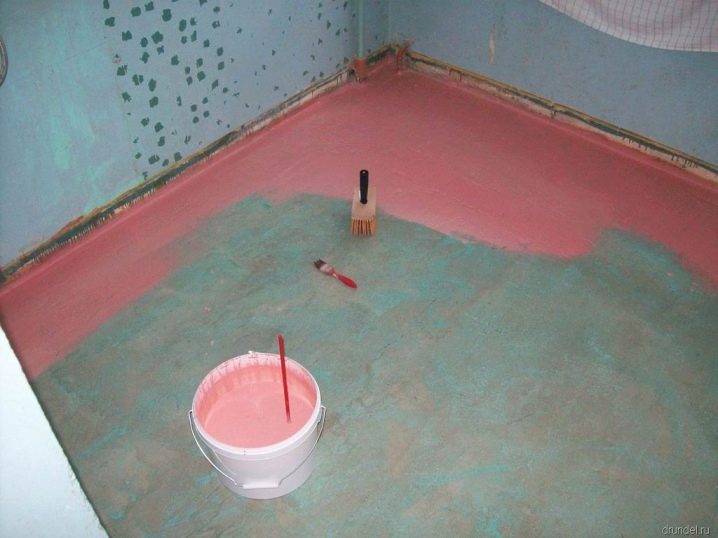

The scope of the material is very wide. For interior work, absolutely all surfaces are treated with it: the ceiling, walls and floor.

At the same time, there are only two requirements for the processed material:

- clean base without dust and oil stains;

- the base temperature is above the zero mark of the thermometer.

The basis can be different. The concrete contact is suitable for working on concrete, wood, metal, glass, tiles, painted and many other surfaces. For almost every type of coating, manufacturing companies offer their own version of the product with slight differences in the composition of the mixture. But such a division is rather arbitrary and in most cases the solution can be used to work both on glass and on concrete with the same type of mixture.

If for internal work priming with concrete-contact is rather recommended, then for external work such treatment is a prerequisite. Without its use, it will be impossible to achieve the desired adhesion between the contacting building materials. In times of harsh weather conditions, cladding materials can quickly peel off from the substrate. This leads not only to a deterioration in the appearance of the building, but also to separation from the surface: if the decoration was carried out with tiles or stone, cases of injury to passers-by are possible.

Why is it needed?

The main purpose is to provide a strong bond between the two materials and to strengthen the base. Improving adhesion is necessary not only on the ceiling and walls, but also when installing a floor screed. Concrete contact is used both under concrete and cement-sand screed, and under the self-leveling floor. As a result, the finished surface is not isolated layers, but a solid and solid structure.

On concrete wall slabs, which have a particularly smooth surface and poor moisture absorption, the use of such a solution is mandatory. Without it, plastering or painting the wall will not work. Finishing materials will not stick or quickly crack and crumble from such a surface, and the wallpaper will simply not stick.

Concrete contact is a convenient modern replacement for wall banding, which was used in the Soviet and post-Soviet period. For the device of this design, the entire surface of the walls was pasted over with a mesh of fabric. Common PVA glue was used for gluing. This method was not only difficult, but also did not always lead to the desired result.

By using a concrete contact, it is also possible to save yourself from labor-intensive and expensive work on cleaning the surface from the old coating. This mixture can be applied to oil paint and tiles. At the same time, the quality of the final result will be no worse than when applied to a surface cleared of them. It remains only to strictly follow the manufacturer's instructions, observe the technology of use and perform all work within the specified time frame.

Besides good adhesion to the surface, improved adhesion and versatility, concrete contact has another important feature. After the composition dries, a waterproofing layer forms on the surface, which will not be superfluous for both internal and external work. But this quality is especially important for the preservation of plastered surfaces for the winter. Under the layer of concrete contact, the plaster coating will remain as smooth and dry as it was before the frost.

Types and characteristics

The main difference between the types of concrete contact is the size of the quartz sand particles, on which the choice of surface for processing with this mixture depends. In addition, there are primers that are intended for indoor use only, and a combination primer for exterior and interior use. The primer packaging always contains instructions describing the materials suitable for processing. It is worth trying to take into account the manufacturer's recommendations, this will reduce the consumption of the primer and get the desired result.

As part of a concrete contact, the following components are necessarily present:

- Cement or Portland cement;

- Finely dispersed quartz filler;

- Polymer, most often acrylic, component;

- Special technological additives.

The technical characteristics of the composition do not depend on the manufacturer, the type of mixture and are always the same:

- Environmental friendliness. The composition does not have an unpleasant odor and vapors harmful to health. To work with it, you do not need personal protective equipment for the hands and respiratory tract.

- Resistant to alkalis and aggressive environments.

- Waterproofing properties.

- It is permeable to gases, which creates the correct air circulation in the room and prevents the formation of mold.

- Resistant to parasites, mold and mildew.

- Drying speed at room temperature and moderate humidity is only 2-3 hours.

- The service life declared by the manufacturers is 80 years. After this period of time, the concrete contact layer begins to collapse.

- The air temperature for work is 5-35 ° C, the recommended humidity is 60-80%.

To make the layer thickness and the uniformity of the coating easy to control, manufacturers add a white or pink dye to the mixture, which is clearly visible on the treated surface. Without dye, the concrete contact is a clear liquid.

The solution can be applied to any surface either manually or mechanically using a compressor or spray gun. There are options for using mechanical devices, this must be indicated in the instructions. In addition, specialized stores have a selection of mixtures in aerosol cans.

Any type of concrete contact must comply with GOST 28196: according to its characteristics, it belongs to water-dispersion compositions with an acrylic copolymer. If the GOST number indicated on the package is different, it is better to refuse such a purchase.

The consumption of the mixture per 1 m² depends not only on the size of the sand particles, but also on the porosity of the treated surface:

- for smooth and slightly porous surfaces such as painted walls, metal and glass substrates, ceramic tiles, the consumption of the mixture will be about 150 g / m².

- for a medium-porous surface made of concrete slabs or finishing bricks, the consumption will fluctuate within the range of 300-350 g / m².

- for a highly porous surface, such as concrete or building bricks, the consumption can be 500 g / m² or more; to reduce the consumption of concrete contact, the surface is covered with a deep penetration primer.

Subtleties of use

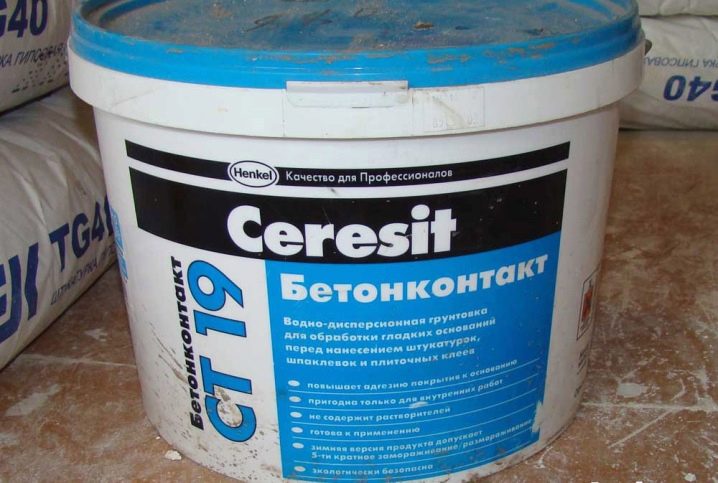

Concrete contact is sold ready-made in containers with a volume of 3, 5, 20 and 50 liters. In order to get started, you just need to open the lid and mix the composition so that the quartz filler is evenly distributed throughout the mixture. Stirring must also be repeated periodically during operation.

Before proceeding with the application of the mixture, the surface to be treated is carefully prepared:

- a coating that does not adhere well to the base must be beaten off or scraped off;

- remove greasy stains, glue and bitumen drips;

- clean the surface from dust and wait for it to dry completely.

It should be noted that it is necessary to process the base with concrete contact immediately after it has dried. If a new layer of dust settles, cleaning from it will have to be repeated again. The concrete contact does not adhere only to dusty and greasy surfaces.

Very few tools are needed to apply the mixture:

- wide brush, roller or spray gun;

- stirring stick;

- container with concrete contact.

The concrete contact can be applied with a roller, but it is better to replace it with a wide brush. This way you can achieve a smoother coating and better penetration of the composition into all cracks and pores in the base. The mixture can be diluted with water, but only in cases where it is allowed to use mechanical methods for application: this possibility is indicated in the manufacturer's instructions.

On a painted wall or drywall, on the contrary, priming is better done with a roller. With other methods, you can get too thin and weak layer. The brush and stained surfaces should be thoroughly rinsed immediately after completing all actions. Uncured concrete contact is very easily washed off, and there is no way to remove the hardened composition.

3-4 hours after applying the primer, it will not be superfluous to check the quality of the resulting coating. It is easy to determine by the dried layer if there are gaps or places where the primer has completely absorbed. If such flaws are found, the surface must be coated again with the same compound. You also need to check the strength of the layer, which for this needs to be scraped with a knife or spatula. A well-applied material will not fall off or deform.

It is recommended to start applying gypsum plaster or tiling on the surface no later than 12 hours after the surface has dried. The dust quickly enough settles on the finished rough layer and impairs its penetrating properties. If after drying two or more days have passed, the surface must be additionally treated with a deep penetration primer.

Manufacturers

In the conditions of the modern market, many manufacturing firms offer their own version of concrete contact. There are both very cheap and very expensive offers. The final decision on which composition to use is always left to the consumer. But nevertheless, it is better to understand in advance the main suppliers of such a product.

V concrete contact Axton in addition to the standard set, marble chips are included. Used for indoor and outdoor applications. Among consumers, the composition is in good standing. The only drawback is complaints about the high consumption of the mixture. The average price is 300 rubles for 6 kg.

Concretecontact from the company "Optimist" intended for work on old tiles, on durable layers of alkyd or oil paint. It is used for both outdoor and indoor work. Consumption of the mixture is 200-300 ml / m². The average price is 500 rubles for 6 kg.

Concrete production firm "Bolars" also suitable for work both inside and outside the building. Suitable for both concrete and smooth tiled surfaces. It is produced with fractions of 0.3-0.6 mm and 0.6 mm.The price for a package of 5 kg is within 300-350 rubles.

Betonkontakt "Bitumast" not much different from their fellows. Produced by ChemTorgProekt in St. Petersburg. Suitable for outdoor and indoor use. The average price is 700 rubles for 7 kg.

Betonkontakt from company "Kreps" has a quartz sand fraction of 0.4 mm. Mixture consumption from 170 g / m². Suitable for both indoor and outdoor use. The average price is 400 rubles for 4 kg.

Bettokont from firm "Osnovit" also suitable for any work, but it has a higher consumption of the mixture. The manufacturer indicates the consumption at 450-500 g / m². Moreover, the cost of 6 kg of the composition will not exceed 450 rubles.

The most important thing when purchasing a mixture is to shop only in specialized stores and choose goods from well-known manufacturing companies. For more confidence, it is recommended that you read the reviews on the Internet.

Reviews

As you might expect, the reviews about Betonokontakte are positive in most cases. Disputes about which manufacturer of the mixture is better has not yet been found. But occasionally there are negative responses, but they are more about sellers than about manufacturers.

On one of the forums, a man told a terrible story that after applying concrete contact to the ceiling and its subsequent whitewashing, the result was not pleasing. At first, pinkish reflections could be seen under the layer of white. A week later, the whitewash began to chip off along with the primer.

Professional builders in this case explain that either the composition was purchased with an expired shelf life or after repeated freezing, or a fake was purchased.

Unfortunately, there are such cases. Therefore, if the purchase of a concrete contact occurs not in a specialized store, but on the market, then it is better to open the container and check the homogeneity of the mixture. If the solution is not homogeneous, the purchase should be discarded.

Recommendations

The concrete contact must not be applied in front of the cement-mix plaster. The tear-off strength of the film after such a primer is 0.1 MPa less than necessary for cement-based mortars. Therefore, plastering with cement compounds should be done only on concrete.

When buying a primer, you need to pay attention to the production date and storage conditions. It is recommended to use only formulations that have passed less than a year since the production date. If the concrete contact was stored incorrectly and was subject to freezing, it makes no sense to use it. After thawing, this mixture loses its adhesion properties.

To reduce the consumption of concrete contact, the surface is pre-coated with a deep penetration primer. If the substrate is too dry and porous, the primer must be applied again after the first coat has dried. Processing with concrete contact is possible only after the soil has completely dried.

What is concrete contact, see below.

The comment was sent successfully.