How to choose a mounting clamp?

In recent years, mounting clamps have become increasingly popular and are increasingly used in construction. There are several types of clamps that can be selected depending on their intended purpose.

What it is?

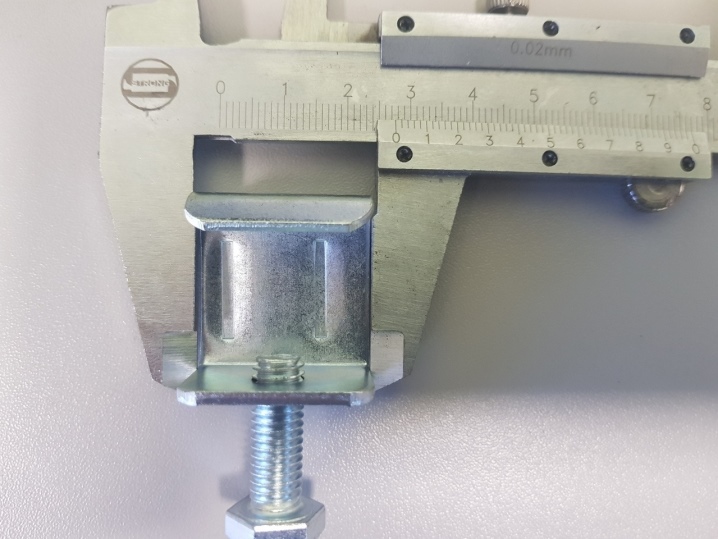

A mounting clamp or, as it is also called, a beam clamp is a durable steel product, most often U-shaped (sometimes C-shaped), which is used to fix parts and ensure their immobility. This support tool plays the role of a so-called "helper" for fastening building structures of any complexity.

The metal clamp consists of two parts. The core part is a U-shaped base made of galvanized metal alloys. A hole is drilled in the jaw (one of the sides) for a movable bolt of a certain size. Tight fixation of the clamp is achieved by moving the bolt, thus reducing the distance between the movable element and the jaw.

This is a very practical fixture with a fairly simple design that will help to firmly hold both metal pipes and wooden parts.

Mounting Clamp Benefits:

- light weight and mobility;

- saving the time of the master at work;

- reliable fastening, regardless of the weight of structures and parts, fixation in a comfortable position;

- the ability to use the clamp when working with a variety of materials (wood, metal, glass).

Device

After installing the clamp, the bolt is fixed with a screw, which is located on the movable side of the clamp. There are several types of beam clamps, depending on where they are often used: at home, in the garage, in carpentry workshops and car services.

Universal clamps

- G-shaped The clamps are equipped with a screw clamp, which is usually used for fastening heavy and large parts.

- F-shaped clamps are less stable than G-shaped clamps. The main feature is the wide range of adjustments. With the help of this model, the parts are pressed against a fixed surface and can simultaneously fix several structures.

Functional clamps

- Corner. This design is used to create a right angle and is equipped with two helical jaws. Through holes on the main part make it possible to fix the additional tool to the vertical plane. Weaknesses include the limit on the size of the processed parts.

- Belt (belt). They are mainly used in workshops by coopers and carpenters. The tool consists of a tensioning mechanism and a lamellar belt or belt for easy grasping of massive round products. Evenly distribute the load, such clamps are well suited for gluing corner joints. Often used for the assembly of round tables, in plumbing, as well as in the manufacture of barrels.

- Quick-clamping (automatic) clamps. Such devices are also called trigger devices due to their F-shape. The device is an iron bar with a movable lip with two triggers on one side, and a removable fixed lip on the other. Such a tool is quite practical to use, as it is equipped with an automatic mode and is used with one hand.

- Automatic clamps - an integral element in the toolkit of every master who is engaged in locksmith or carpentry work.

Criterias of choice

We will reveal to you a few key points that will help you in choosing the right clamp and will greatly simplify the work.

- The main criterion is the quality of the material. Mounting clamps are constructed of cast iron or steel alloys. When disposing of clamps, considerable effort is made, which is why it is necessary that the device can withstand shock loads without damaging the integrity of the material itself.

- Features of the thread on the clamping screw. The use of a coarse thread (thrust or trapezoidal) is recommended for maximum tightening.

- Special angles on the surface of the clamps. Their main task is to prevent damage to the processed materials. Very often wooden blocks are used for this.

- Particular attention is paid to the clamp. In order to eliminate distortions, the device should not merge with the rest of the body, and the pressure pad should have a maximum area.

- Convenient handle that will provide complete comfort in using the tool. It is usually equipped with a rubber or wooden handle.

Application

A mounting clamp is characterized by a number of advantages in use: when installing structural systems, welding and drilling can be avoided, it can withstand a load of up to 2.5 kN, thanks to this device, installation is much budgetary, does not need additional investments.

The clamp is installed with a pin that goes through the unthreaded through hole to make it easier to attach the screw. The ventilation collar is attached from the opposite side. Using nuts and locknuts, the stability of the stud is fixed in order to prevent spontaneous twisting.

Pipe clamps are most often used for gluing huge panels, which are later used in the creation of countertops or doors. The device is a metal tube with two attached jaws. One of these jaws is stationary, while the other moves and is fixed with a latch. This tool is very long and therefore more difficult to use.

The purpose of pipe clamps is to create shields, and the tool is practically not suitable for fastening small parts.

Spring clamps do not differ in their functionality, since they allow you to adjust the compression forces. The design of this tool consists of a spring, which creates forces. Typically, such models are used for delicate work, including for laying power supply cables.

The mounting clamp is an important part of the arsenal in the workshop of every carpenter or cooper. It is often used for laying trays for low-current systems, fastening air duct screws in an air conditioning and ventilation system, as well as when installing engineering systems.

In the following video, you can watch an overview of the welding and brazing clamp.

The comment was sent successfully.