Everything you need to know about roof trusses

When building any roof, the most important thing is safety and reliable protection from negative environmental influences. To achieve this, wood or metal rafter systems must be used.

What it is?

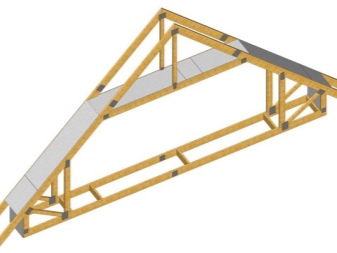

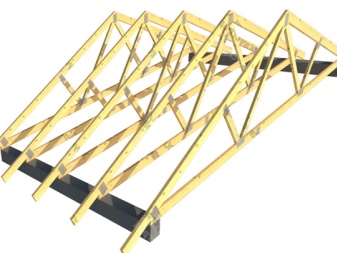

A rafter truss is called a whole complex of structural elements, which includes a crate, braces, racks. After assembly, the structure will become a reliable "skeleton" of the future roof.

A truss truss is primarily understood as a rigid structure, which is relevant for the construction of pitched roofs. The main task of the truss is to distribute the main load, which is exerted by the walls of the structure. Most often such structures are made of wood, but installation from similar materials is possible.

The basis for the construction of a wooden typical structure is rounded beams, ordinary boards. Additional elements are attached to the main structure, literally cutting into the necessary areas. If the parts are made from planks, the attachment involves bolts, keyways, and nails.

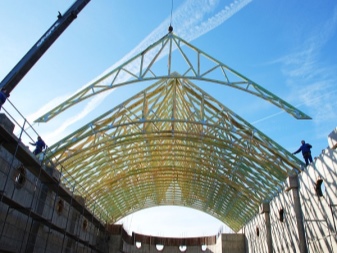

Trusses with stretched metal foundations are used in the construction of large-scale buildings, when the span has a length of more than 16 meters. If we are talking about erecting a structure using stretched racks from boards, then it is difficult to achieve the reliability of fastening the nodes. However, if you use metal elements, then it is quite easy to firmly fix the nodes.

It takes a lot of effort to assemble a wooden truss. The process will go much faster if you use not only wooden parts, but also metal ones. This type of assembly is called combined.

When building residential buildings, it is extremely rare for planners to resort to the open truss roof option. Most often, farms are simply closed with special ceilings for the ceiling. When constructing industrial buildings, open farms are left on the roof.

The load-bearing parts of such a structure are often beams. Construction beams are made on the basis of reinforced concrete, are laid under the rafters and overlap the steps of columns 12, 18 m long. These parts of the structure serve as an intermediate support.

Primary requirements

Regardless of the type of building materials, before the main finishing, it is necessary to build a strong and reliable structure, whose main task will be the stability and strength of the roof.

If the structure with elements from the rafter and rafter complexes was erected correctly, then its reliability is guaranteed. The structure can easily withstand any type of load, be it temporary or permanent.

The material and structure of the truss requires maximum strength, safety and stability.

Species overview

When choosing the type of structure and the material from which the skeleton of the roof will be made, the material of the walls themselves should be taken into account. Columns made of metal or reinforced concrete, subrafter systems and brick walls will become a reliable support for load-bearing foundations.

The characteristics of the trusses make it possible to classify them according to these parameters:

- architectural design of the structure;

- static circuit;

- type of lattice;

- the outlines of the rafter belts.

The most important criterion for the classification of trusses is the shape of the belts.It is calculated taking into account the parameters of the span, structural features of the roof, as well as taking into account the level of possible load. The choice of material also directly depends on the slope (the slope of the belt at the maximum height is taken into account).

- When erecting flat roofs, trusses equipped with parallel belts are most often used.

- If steel or asbestos-cement sheet floors have become the material for the construction of the roof, then a supporting system in the form of a trapezoid will be the best option.

- In private construction, most often you can find designs of triangular configurations.

- Taking into account the variant of the outlines, the choice of the lattice is also carried out. If systems are used in the form of a trapezoid or varieties with parallel belts, then the best option is the lattice of triangular shapes. The lattice is reinforced with additional posts.

- Grids equipped with trusses are often used.

On the basis of constructive design

All trusses can be divided according to the design of the structure:

- for heavy (double-walled), with two shaped sheets in the nodes of the structure;

- lightweight (single-walled), in the construction of which there is only one sheet.

When constructing buildings with a long span (industrial buildings), heavy structures are used. When erecting huge industrial premises, the "skeleton" of the roof acts as a frame on which the supporting systems rest.

By material

According to the types of material, truss systems can be created:

- made of wood;

- of steel;

- combined.

Shape Tips

Let's consider how to make the right choice of the molded configuration of the structure. For the selection of the form to be correct, the following criteria are considered important:

- type of roof covering material;

- whether or not there is overlap on the ceiling;

- roof slope;

- features of the connections of rafter elements.

When building a flat roof covered with bitumen rolls, it is better to use rectangular or trapezoidal structures.

If the slope of the angle is greater than 12 degrees, and if the pavements are heavy, then it is better to use structures in a triangular format.

Material selection

The most responsible and important is always the choice of material for construction. Special requirements are imposed on the material: it must provide the highest strength, be sufficiently rigid and not deform. The price indicator is also relevant, since cost is a rather tangible factor, especially in private construction.

Wood

Wood is considered one of the most popular and inexpensive building materials.

Wood structures are relevant for the following cases:

- when erecting roofs like an attic;

- when installing both industrial and other facilities;

- during the restoration of flat roofs of various buildings.

The main features of timber trusses, in comparison with similar structures, are the following:

- design speed has been increased several times;

- automation of the installation and simplicity of all stages of construction;

- simplicity during installation work (the elements are already ready, you just need to install them correctly);

- the ability to implement even the most daring design ideas in terms of configuration, shape and other aspects;

- the design weighs relatively little;

- possibility of installation in situations where spans are large (maximum length - 18 m);

- the ability to carry out insulation, the general simplicity of this procedure;

- excellent technical and operational qualities;

- the material is considered suitable for processing in an industrial environment, which means it belongs to the first category of materials for fire safety;

- environmental friendliness.

Metal

Steel structures made of shaped pipes boast increased rigidity, unlike wooden competitors.Due to this quality, metal rafter systems are often used if the structure needs to be given additional rigidity. This is a good option if long trusses are installed, over 10 meters. In this situation, not only the rafters must be made of steel, but also the ridge supports and the Mauerlat beam.

Installation should not be carried out using connecting wood parts, but using special channel profiles.

To fasten the rafter bases, corners are required that have been pre-welded.

The main advantages of steel trusses:

- higher strength compared to other options;

- resistance to various corrosion phenomena and physical impact;

- the material is not capable of rotting and has a special resistance to deformation;

- long service life;

- if it is required to close the perimeter of a large building, it is very simple to do this with the help of steel elements.

Some cons of metal structures:

- the structure itself weighs a lot, the use of such elements gives an additional load on the roof;

- during installation, it is necessary to use special equipment (to raise products to a certain height);

- parts do not withstand too sharp temperature changes and may deform;

- quite high cost.

Steel trusses are divided into three types:

- having parallel belts;

- in the shape of a triangle;

- polygonal.

For the construction of a soft roof, roof structures with parallel belts are excellent. You can also use polygon models.

If materials in the form of sheets are used, then triangular structures will be the best option.

The trusses that are produced at the factories are suitable for universal span sizes - 18, 24, 30 and 36 meters in length.

When creating lattices of structures and belts, corners are most often used. The individual elements are held together by welding. The most reliable one can be called a structure, when arranging the belts of which beams with wide flanges (T-shaped) were used.

The production itself is not too complicated, this way of working requires less material. At the same time, the strength and reliability of the structure remain at their best.

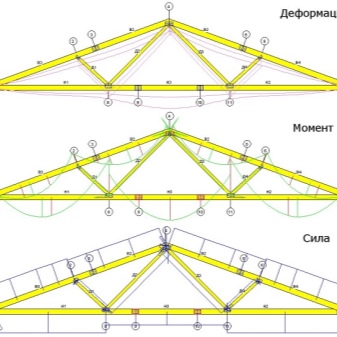

Features of the calculation of loads

When installing a rafter system, it is important not only to correctly determine the best form and material, but also to calculate the planned load.

Loads can be classified into three types:

- unchanged: this type includes the total weight of the roof;

- temporary: weight of snow cover or ice, strong wind flow;

- special type of load: the possibility of an earthquake.

The rafter system, created with beams and trusses, becomes a load-bearing system. Such a system consists of many elements. When installing a specific type of structure and its shape, it is important to understand that this is always a very responsible process. Each stage has its own meaning, but a special place is given to design. All calculations must be made correctly, many factors must be taken into account, because the safety of the future building depends on it.

The calculation is based on the most complex calculations that only a professional can do.

Installation technology

As an example, below is the simplest version of the installation work of the rafter system (used in the construction of a shed roof). Designing can be done by hand.

- First, you need to calculate the level of the difference between the walls in the drawing: tgL x W. The "W" icon indicates the distance between the two supporting walls. The tangent of the corner (roof slope) is indicated by the "tgL" icon.

- After carrying out the calculation, you should prepare the required number of rafters from the boards by treating the wood with an antiseptic.

- This is followed by the construction of the Mauerlat. The board should be commensurate with the diameter of the walls. The beam needs to be strengthened very tightly and rigidly, good waterproofing will be useful.During installation, it is necessary to observe the horizontal position of the structure.

- Then the areas for laying the rafter foundations are designated (after the designation of such areas, recesses are cut).

- The trusses should be located so that they go to the ledge along the supporting structure by about 30 cm. The fastening can be done using construction brackets and special bolts.

- The result of the work will be the laying of the crate and props. If the base of the rafters exceeds 4.5 meters in length, then the supports are simply necessary. On top of the installed structures, lathing strips are laid.

You can find out how the assembly of a devian truss truss takes place in the video below.

The comment was sent successfully.