All about sliding rafter supports

The roofing structure made of wood tends to deform over time. This moment is associated with natural changes in wood, its shrinkage under the influence of the environment and precipitation. In this regard, during the arrangement of the roof, technologies must be used that prevent the processes of sagging and stretching of structures.

Features and need for application

Nowadays, wooden roofs are in great demand. To make it last as long as possible, the masters advise you to start installing sliding supports for the rafters. This device is necessary in order to connect the parts in the rafter frame with the formation of a power reserve, thanks to which the pitched roof does not deform when sitting down.

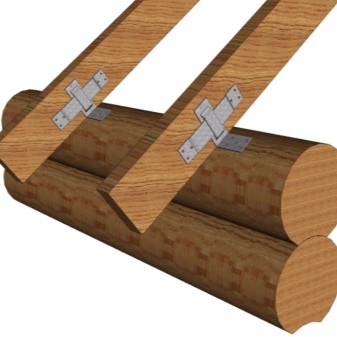

Supports are widely used in log houses, as well as in log cabins. The people call them sliders, sleds.

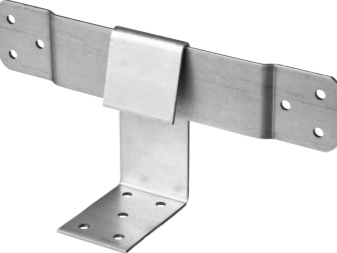

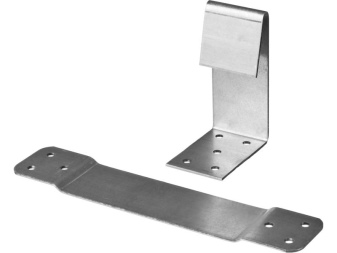

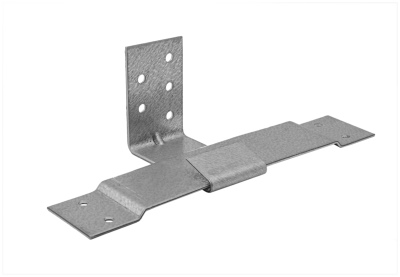

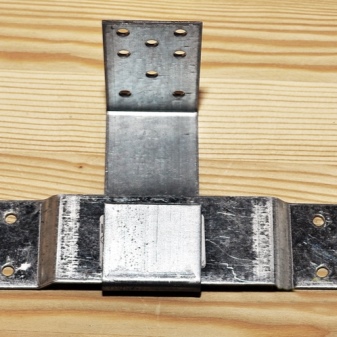

As part of this roof element, there are two parts, namely fixed and sliding. Sliders are often made from a durable and corrosion-resistant material that can withstand heavy loads. According to GOST 14918-80, in the production of sliding rafters, low-carbon steel is used, which is characterized by high strength.

The slide is based on a metal bracket and a corner with hinges. They are characterized by standard dimensions:

- thickness - 0.2 cm;

- width - 4 cm;

- height - 9 cm;

- length - from 9 to 16 cm.

Low carbon steel contains a small percentage of carbon, so the material is easy to process. To increase the strength of the sled, manufacturers use a deoxidation method. These structures are manufactured using cold stamping technology. To protect the supports from corrosion, they are hot-dip galvanized. This procedure prevents premature failure of the fasteners.

If there is no factory galvanic protective layer on the slider, then before starting to use the product should be treated with oil paint. The latter is able to protect the material from rust. When choosing sliding roof supports, one should take into account the weight of the product, as well as the force of the load on the surface in the event of snow and wind.

Despite the need to purchase materials, costs of your own efforts and time, the sled has the following advantages:

- no complications in the installation mechanism;

- reliability and strength of the structure;

- ease of use over the years;

- small financial costs.

As practice shows, a house made of logs, which has sliding supports, lasts longer. In addition, if the sliders are treated with special compounds in advance, then such structures can be erected in areas with unfavorable climatic conditions.

The roof of a building with "sliding" is able to withstand strong winds, frost, temperature changes and stand for tens of years, while being suitable for living.

Similar elements of a wooden roof are necessary to perform such tasks:

- prevention of deformation of rafters during shrinkage of a building from a wooden bar;

- ensuring the possibility of movement of the frame during use.

Species overview

A rafter sled secures the roof legs to the Mauerlat. Typically, galvanized sliders have typical dimensions and construction with statistical guides and a hinge angle. Movable fasteners are available in open and closed varieties, which are characterized by characteristic dimensions.

Open

The open sliding bearing is a collapsible design. In it, the corner is fixed to the Mauerlat on the rafter frame. Models of such designs differ in the number of fixing holes and the power reserve. The minimum power reserve in this case can be 6 cm, and the maximum - 16 cm. Depending on the value of this indicator, the quality of fastening and protection against surface deformation are ensured.

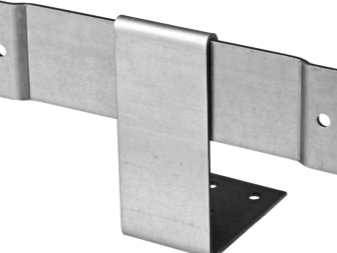

Closed

The difference between the closed sled and the previous one can be called its ability to be assembled and disassembled. The corner in this case is equipped with a loop. A guide bar is threaded through it, which is mounted on the rafters.

According to professionals, open sliding bearings are characterized by ease of installation. This point is very important if the work is done by an inexperienced master. If you look from the other side, we can conclude that closed sleds are more reliable in use, as well as the ability to withstand heavy loads.

Installation technology

The installation of a rafter roof frame has no peculiarities and is carried out according to the standard scheme. However, in order to in order to correctly install the structure, mount it to the Mauerlat and maintain the same angle at the border of the roof base and rafter leg, you will need to make a preliminary drawing.

The scheme according to which it is worth fixing parts of the rafter systems is as follows.

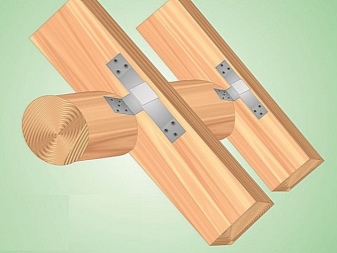

- First of all, the master will need to lay the Mauerlat on the load-bearing walls of the building. This structural element performs a supporting function. He is able to evenly distribute the load and transfer it to the foundation. If the building is made of logs or beams, then the upper type of crown can be used instead of the Mauerlat.

- A rafter leg template is erected. It acts as a model by which the remaining rafters will be executed in the future.

- At the end of the rafter leg, a gash is made for the Mauerlat. If the cuts are made directly in the Mauerlat, then this can lead to a decrease in strength and a deterioration in bearing capacity.

- Initially, the first and last rafter legs are fixed. In this case, it is imperative to check the connection and the angle at the border of the elements. To complete the procedure, you must put a building level.

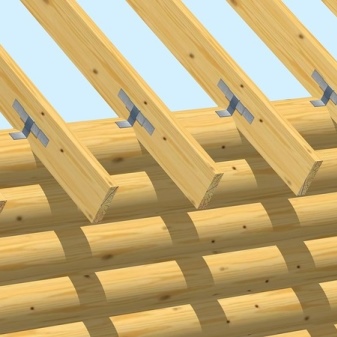

- At the end of the leg, it is required to fix the sliding rafter support. To improve the reliability of fixation, guides and runners are attached. The work is done with the help of several hardware.

- The upper rafter legs are mounted using metal plates or nails. The latter can be connected with a pin, on which the mobility of the elements depends.

- At the border of the first and last rafter pairs, you need to pull the cord, as well as install the remaining elements of the structure.

Rafters, like brackets, must be fastened with particular reliability. If you just rest it against the beam, then the end will slide. Because of this moment, the entire roof can collapse. Some craftsmen fix the supports with puffs, but this method is not widely used.

Experts advise installing sliding supports for rafters using special self-tapping screws. A conventional self-tapping screw is not able to withstand significant loads that will occur when influencing the movable parts of the structure. In order for the rafters not to collapse under their own weight, the craftsmen must adhere to a special work technology.

This is the only way to rely on reliable construction of sliders.

In order for the roof to last as long as possible, it is worth listening to the following recommendations of professionals.

- The sled should protrude as jumpers when connecting the upper crown and rafter leg.

- The guide fence is fixed parallel to the rafter leg.In this case, the installation of the angle must be perpendicular.

- Do not forget about the processing of each composite wooden roof element with special substances.

- Supports are required to be installed on systems with the correct proportions.

- Ridge joints can be fixed with bolts, pins, hinges.

- For ease of installation, it is worth using rafters with the same dimensions.

- When performing installation, you can use the technology with the extension of boards. This technique is used to work out long spans. In this case, the elements are connected with long hardware, and the wood is overlapped.

Incorrect installation of the sliding rafter supports can lead to problems in the free movement of parts relative to each other. The friction that will occur will subsequently damage the fasteners, and will also cause the plates to jam and tear off the corners. In order for the roof to fulfill its intended purpose for many years, before and after the winter period of the year, it is worth carefully examining all the connections on it. Also, experts categorically do not recommend insulating the roof, on which there are sleds.

Sliding rafter supports are an essential element of every roof. Their installation allows you to keep the roof strong and airtight for decades. The main thing is that the installation is carried out with special care and using the correct technology.

In the next video, the information is presented more clearly.

The comment was sent successfully.