Building level: what is it, how to choose and use?

When performing any construction and finishing work, the level is an indispensable tool. It is necessary during the installation of door structures, windows, as well as when laying tiles or bricks in order to check the verticality. With the help of the building level, they also carry out the installation of built-in household appliances and engineering connections.

Description and purpose

The building level is a measuring device used to control the installation of materials and structures in the horizontal and vertical planes. The main parameters of any level are:

- measurement accuracy - the larger the tool dimensions, the lower the error will be.

- impact resistance - in most cases, the building level assumes a hollow body, while its wall thickness can reach 100 mm in order to withstand mechanical shock;

- resistance to bending and twisting.

Measuring flasks of any level are characterized by an increased level of transparency and resistance to discoloration, cracking and liquid leakage in the event of temperature extremes or UV radiation.

Typical levels represent a rectangular cast body, the lower edge of which is milled. Usually they are made from strong, but at the same time, lightweight materials (for example, plastic, wood, as well as polystyrene or aluminum with an anti-corrosion coating). Depending on the ultimate measurement accuracy, a certain number of glass flasks are provided in the body, inside of which an alcohol-containing liquid with an air bubble is poured. If there is only one flask, a similar level can be used exclusively for a horizontal guide, a pair of flasks allow measurements to be made horizontally and vertically, and three or more are used for complex work when it is necessary to measure the slope parameters.

Risks are applied on the surface of the instrument - dividing lines, eyes for alignment have special reflectors, and plugs are made of plastic. On the ends of the tool there are pads that protect the mechanism in case of accidental fall. For the most comfortable bubble control for the eyes, the liquid may contain fluorescent components, so that work can be carried out in the evening and at night.

Varieties

Bubble-type devices are most widely used, their design is simple, intuitive and versatile. The measurement error does not exceed 1 mm / m. This device is manufactured in strict accordance with the current GOST 9416-483. The body is of a simple design with strong stiffeners, the size of the tool varies from 30-50 cm to 5 meters or more. To reduce the weight of the structure, the level is made of aluminum alloys, and the ampoule is made of extra strong glass. A scale for measurements is provided near the base.

Magnetic bubble levels are mainly used to work with metal structures. Their characteristic feature is the presence of built-in magnets, which makes it possible to fix the device in an upright position on metal structural elements. Products with a reinforced monolithic body are more suitable for working with stone.If you are going to carry out complex measurements, you should give preference to combined products that combine the features of both types.

Electronic models with a goniometer are usually referred to as expensive measuring equipment; they have two or more cameras at once in order to assess the horizontal and vertical of the processed planes. Unlike typical standard products, these devices are characterized by a set of additional functionalities: one of them is a display that visually displays the size of the deviation of the measured planes with a high degree of accuracy. In addition, they provide the option to record the measured values. An audible indicator is provided in the electronic mechanism - it gives a signal when it reaches 0 or 90 degrees.

For aligning the horizontal and vertical lines of water, sewer, and gas pipes, the pipe level is optimal. It can also be used to work with any round profile.

Some construction and repair work requires the use of a hydro level, it is needed to apply correct markings in a horizontal position on several objects located at a distance from each other. With the help of such a device, floor beating is carried out, the foundation is installed for brickwork, as well as the installation of metal structures in a single plane. The hydrostatic mechanism looks like a pair of vessels held together by a transparent tube. Before starting operation, the system is filled with liquid, no kinks and breaks of the tube are allowed - the liquid must flow freely from one container to another.

Laser models are better known as levels, they belong to the category of professional equipment. The cost of such devices is high, but they provide many additional advantages:

- increased marking accuracy - the error parameter does not exceed 1 mm / m, depending on the type of mechanism;

- technical parameters of laser levels allow measuring vertical, horizontal and inclined surfaces at a distance of up to several meters from the measurement area.

Top brands rating

Nowadays, in retail outlets, you can find levels of a wide variety of firms that can have a different set of functional characteristics and, accordingly, different costs. TOP manufacturers includes firm "Stabila", the cost of their level varies from 700 to 2000 rubles. Devices of this brand are distinguished by such advantages as:

- high quality and stable reading of indications;

- low measurement error;

- high ergonomics of models;

- precise body geometry;

- low weight of the product.

Magnetic levels equipped with small slots are made under this brand - such mechanisms are in demand when working with electricity, since they allow marking for switches and sockets. The review of the best manufacturers can include Shark company... The brand is famous for constantly updating its model range and relentlessly introducing advanced technologies for the manufacture of measuring equipment.

The products of the German company are famous for the highest quality, practicality and reliability. Bosch... Instruments similar to it in their technical and operational characteristics are produced by the domestic firm "Condtrol"which is much more affordable in terms of cost. Products manufactured by under the brands "Matrix", as well as "Brigadier" and "Stayer"... They are distinguished by increased measurement accuracy and an advantageous price / quality ratio.

Tip: When buying a building grade, well-known brands are definitely preferable.Nevertheless, when choosing a device, the brand should not be a basic indicator, the most important thing is to determine the parameters of future use, namely the nature of the planned work and the frequency of application of the level.

Measurement accuracy

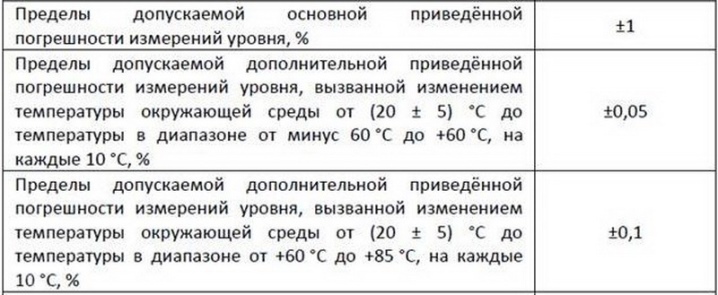

The main thing to remember when performing any work with the level - this is the amount of permissible error that these measuring devices can give:

- the bubble instrument has a measurement accuracy of 0.5-1 mm / m, while the longer the level, the lower the error;

- the error of the pipe mechanism largely depends on its dimensions - the lower it is, the higher the deviation will be;

- hydrolevels ranging in size from 1000 mm to 25 m have a maximum error of 2-3 mm;

- the electric tool has a fairly high degree of accuracy, the size of the error does not exceed 0.1 degrees;

- laser models are the most accurate, their error is on the order of 0.1-1 mm / m.

You can always define accuracy at any level. It is quite simple to do this - the method is called "180 degrees". In order to check the work, it is necessary to place the building level on a smooth horizontal density as tightly as possible so that there are no gaps, and fix where the bubble is located in relation to the risks, and then in the horizontal plane simply turn the device 180 degrees and fix exactly on that the same site. If the instrument is highly accurate, the location of the air bubble will be unchanged. Similarly, you can check the accuracy of vertical measurements.

How to choose?

In order for the construction and finishing work to be performed efficiently, a practical and reliable measuring device should be selected even before they begin. Nowadays, there is a wide selection of a wide variety of devices, which may differ from each other in their technical features, workmanship and, accordingly, cost. Pay close attention to what goals are being set for you. If you want a tool that can be used for all occasions, opt for bubble designs. They are ergonomic, easy to use and versatile. And most importantly, they have high accuracy. The functional capabilities of the devices are enough to install plastic windows, doors and pieces of furniture, to lay tiles.

Electronic views with a goniometer and magnets will be optimal for those people who decide to take up repair work in earnest. This device has advanced functionality: it allows you to visually display the display data with an accurate reflection of the deviation. Additional advantages of the products are considered to be increased accuracy, the option of recording the obtained readings and the availability of electronic calibration.

If you need to align the pillars of a water or gas pipe, as well as beams, you should pay attention to pipe level options.

When arranging the floor screed, during the installation of stretch ceilings and the construction of the foundation, the water mechanism will be optimal. It is also suitable for fixing areas for sockets so that they are located at the same height. With the help of a water tool, it is possible to make precise horizontal adjustments for adjacent rooms, between which there is no direct visibility. This tool has a fairly budgetary price and is characterized by simplicity.

For people who have an impressive amount of repair work, a professional laser device will be the best choice. The use of such equipment will significantly save time and effort, provide increased accuracy of alignment of planes both horizontally and vertically. This tool is in demand when cutting the floor level and for marking the walls for facing work.

When acquiring any level, you must first examine the instrument.The presence of any visible damage (cracks and chips) is not allowed, the assembly must be neat, and the ampoules with an alcohol-containing solution must be built into the case evenly, any loosening of them is undesirable.

Operating rules

Let us dwell in more detail on the features of the operation of the bubble level. Many inexperienced users make a common mistake - they put the level against the wall with its side. This approach is incorrect, because in this case you are unlikely to get at least some objective data, since a non-existent surface is being measured. The most you can tell is if there are any bumps and irregularities on the wall under the measuring tool.

Let's give an example. Let's say you need to hang a shelf. To do this, you need to pick it up, and put the building level on top and bring it to the intended location. Next, observe the bubble: if it deviates, the shelf must be released or raised. Then you should make notes with a simple pencil and remove the tools. If you need to measure the wall, you need to attach the level with the working surface to the wall so that it is located vertically, and the ampoule is at the top. If the bubble deviates from the wall, it means that the bottom is sticking out and you need to add plaster on top.

In general, users note that working with the level is not at all difficult, but in order to learn how to take measurements correctly, it will take time and care.

For information on how to use the building level correctly, see the next video.

The comment was sent successfully.