All about corner profiles

When performing various repairs, profiles are used. Such structures can have various shapes and sizes. Today we will focus on the features of corner profiles.

general description

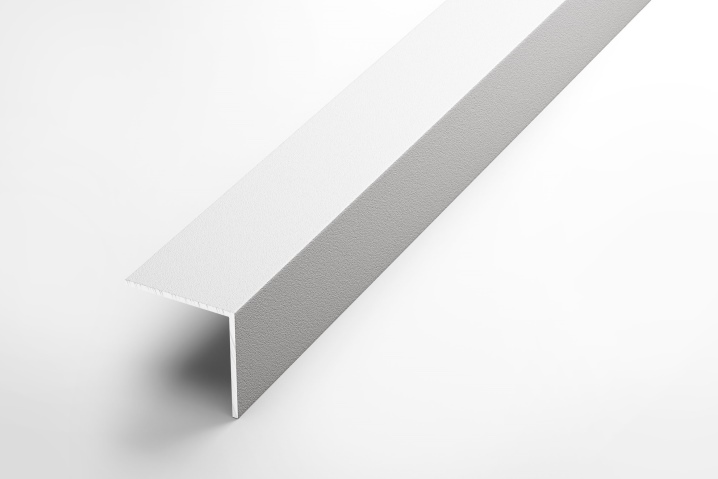

Corner profile structures are intended for reinforcing outer corners (in door and window slopes, in decorative partitions). These areas are considered the most vulnerable, so they need additional protection.

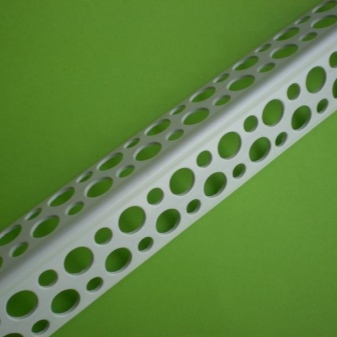

Such products are created with an angle of 85 degrees. The underestimated angle allows you to ensure the most even and tight fit to the surface. Often they are also equipped with a special perforation, which ensures a strong adhesion of the profile.

These corners are easy to install on various surfaces. They have good resistance to deforming loads. And also they are distinguished by long-term operation (the service life can be more than 25 years). These parts can be bought at almost any hardware store at an affordable price.

Views

Currently, various types of such corners are produced. Depending on the material from which they are made, two large groups can be distinguished: plastic and metal models.

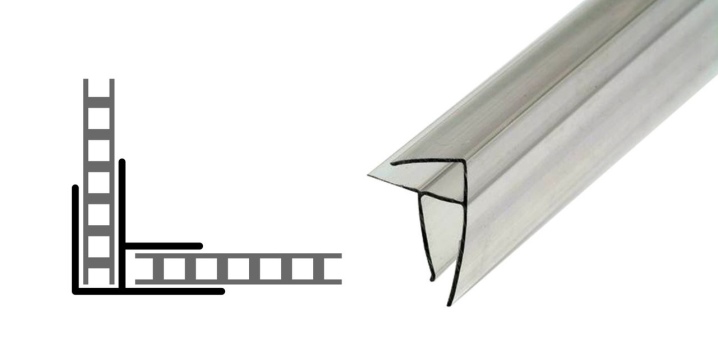

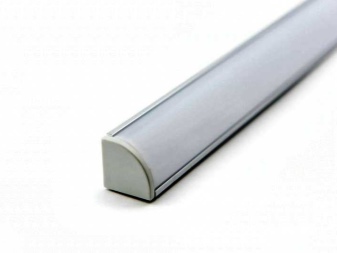

Plastic

These corners are most often made of PVC plastic. They are used mainly in the design of window openings. PVC material is a colorless polymer base, it is considered absolutely safe and environmentally friendly. In addition, it boasts a special durability and decorative appearance.

This plastic is resistant to moisture and sudden temperature changes. The corners are made from PVC sheets by hot forming. Due to such processing, the structure acquires the required shape, as a result, a solid structure with a flat and smooth surface is obtained.

They can be made in various colors - special dyes are added to the material during manufacture. Such triangular profiles can be external and internal. For interior decoration, narrow corners are most often used, wide models should be used for exterior decoration for facade decoration in order to ensure maximum reliability and protection of the finished structure.

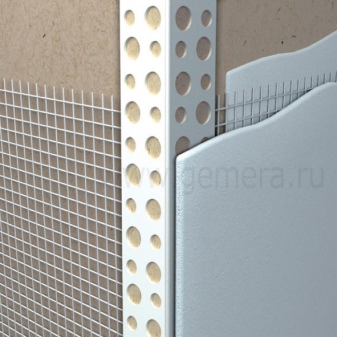

Plastic corners are often made with a special reinforcing mesh. They are intended for durable and reliable fixation of the plaster composition on corners, slopes. They can also be used for internal repair work.

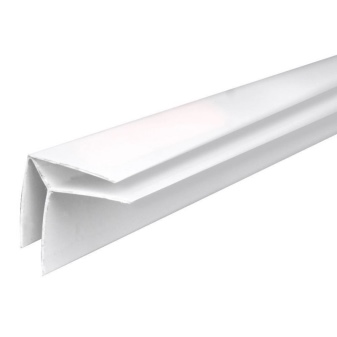

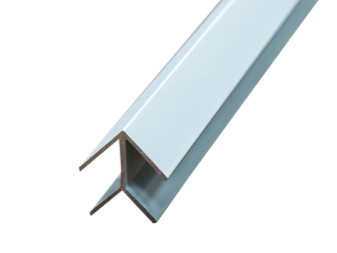

Most often, docking profile corners are made of plastic. They are used to seal joints between different building materials.

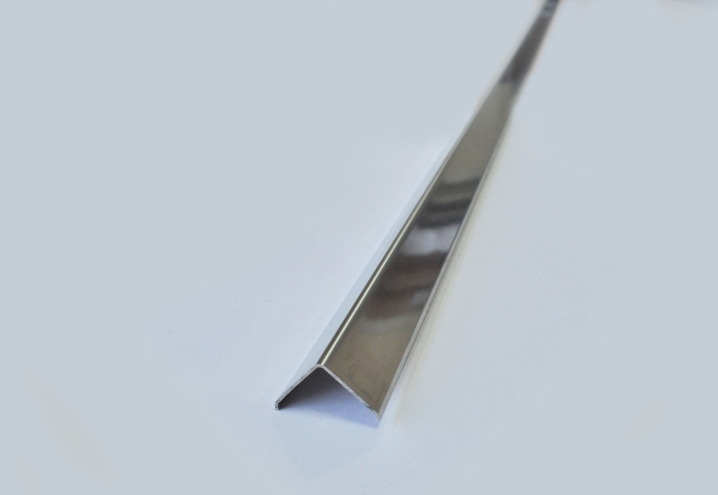

Metallic

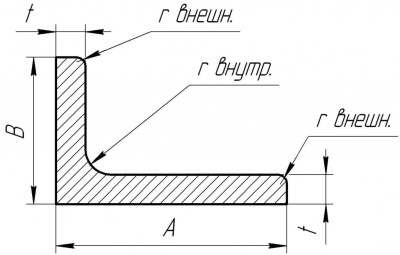

These corners can be of two types: equal and unequal. In the first case, both sides of the structure will have the same dimensions. In the second case, the dimensional values of the sides will be different.

Unequal specimens are intended for non-standard repair work, in which asymmetry plays an important role. This variety is found in stores much less often than equal samples.

Most often, high-quality steel is used in the manufacture of such profiles. This metal is characterized by increased strength and durability. In addition, it will be lightweight, which simplifies the installation process.

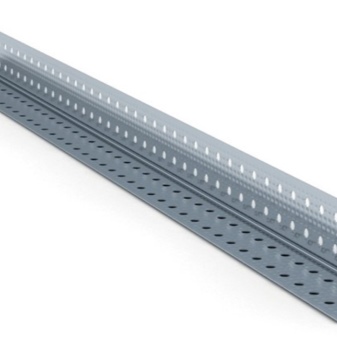

Steel corner profiles allow to withstand significant weight loads. They are often made galvanized.

Zinc coating provides high corrosion protection. Metal profiles with this application can be used for exterior decoration.

And also metal models are often made with perforations. Perforated corners can significantly increase the reliability and strength of the structure. Small holes are most often intended for large hardware. Small holes are needed for nails and screws.

These corners can be universal. They can be used when carrying out construction work with wood, with rafter systems. And also such structures can be reinforced, they are equipped with stiffeners, and can withstand significant loads.

Most often, it is from metal that the wall corners are made. These varieties are also used when installing a false ceiling.

Dimensions (edit)

These profile designs can have different dimensional values. Most often, when performing repair work, models with the following dimensions are used:

-

10x10 cm;

-

10x15 cm;

-

20x20 cm;

-

25x25 cm;

-

20x40 cm.

You can also purchase larger copies of 30x30, 40x40, 30x60, 35x35 cm. They are used when carrying out repairs in rooms with a large area.

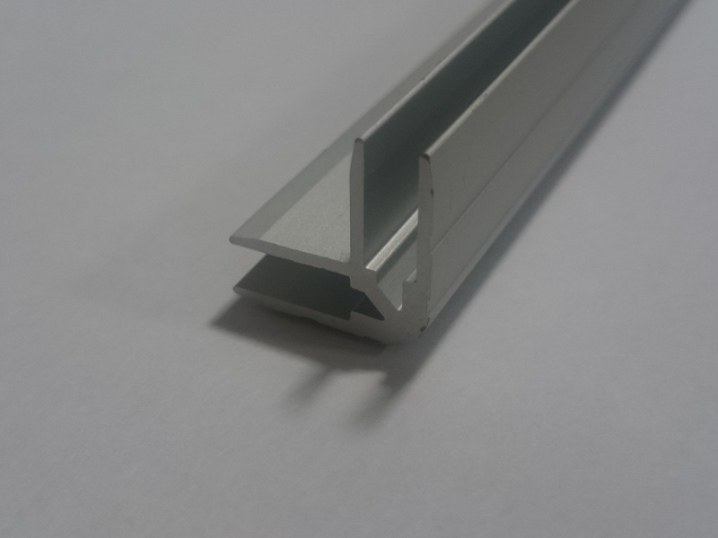

Components

When carrying out repair work with corner profiles, you will also need special accessories for them. These include a dedicated connector. This part allows you to easily and quickly fasten together various sections of profiles. Such connectors are made most often from thin sheet iron. During the production process, the material bends in such a way that, in the end, a reliable connection is ensured.

And also special metal suspensions are used as accessories. They are needed in order to ensure reliable fixing of the profiles to the supporting structure when leveling the walls. They are also used when laying various insulating materials.

Selection Tips

Before purchasing a corner profile in a store, you should pay attention to some significant nuances in the selection of such parts. Consider the material and type of structure to which the products will be attached. There are separate types of corners for ceramic tiles, siding, wallpaper, wall panels, steps, mosaics. There are also certain types that are used in the manufacture of furniture (for countertops).

When choosing, consider the material from which the profile is made. If in the future the structure will be subjected to significant weight loads, then preference should be given to durable metal samples. If the part will perform only a decorative function, then you can pick up a corner made of PVC plastic. The latter can be performed in a variety of colors, so it will be easy to find the right option for any design.

If you need to choose a metal corner profile for facade decoration, then it is recommended to purchase products with a zinc coating. After all, the structure will be exposed to various atmospheric influences. A simple metal profile can rust over time. Galvanized varieties have high protection, they can serve as long as possible.

You need to choose the right option taking into account the size of the corner. If you need to install a large structure, then it is better to immediately purchase larger samples with a large length. This will significantly speed up the installation process, since there will be no need to separately connect several profiles to each other.

The comment was sent successfully.