Corner protection profiles: types and methods of installation

With the help of corner protection profiles, perfect alignment of external and internal corners of all types of surfaces is achieved, and their protection from external influences. Since this useful product is produced in a wide range of colors, has a different texture and height, the product is often used to decorate all kinds of coatings.

Description and purpose

In repair and construction, the correct geometry of the corners requires the use of such a product as a corner protection profile. This is a necessary part for facing openings, preventing destruction from wear on the edges of floor and wall coverings, forming straight and curved abutments to walls and columns, as well as for reliable protection of corners, and reducing heat losses during facade repairs.

The main functions of such products from different materials:

- reinforcement (reinforcement) of corners in order to preserve partitions and finishes from damage, which increases the wear resistance of materials and increases their service life;

- when applying plaster mixtures on the surfaces and openings of niches, windows and doors, such profiles ensure the accuracy of the alignment of the inner and outer corners - cuttings and husks;

- the use of corner protection parts facilitates plastering, in addition, the plaster solution is consumed more economically.

Protective corners are a material necessary to maintain the rigidity of corners, and are extremely in demand when carrying out painting and plastering works, when lining rooms with gypsum fiber sheets and drywall.

Types, materials and sizes

For finishing various coatings and structures, you can use different types of carbon protection products, differing in material and size.

Aluminum

The most demanded aluminum profile is a detail that has many advantages, very valuable for all kinds of facing work:

- aluminum is characterized by sufficient strength, which makes it possible for long-term operation, at the same time it is plastic and, due to its flexibility, can be easily processed;

- this environmentally friendly material is not afraid of moisture, which is due to its high wear resistance;

- one of the positive characteristics of aluminum profiles is their low weight, which reduces the load on the facade structure and facilitates the transportation of products;

- during the installation of the product, it fits snugly to the outer and inner corners, this is due to the shape of the profile section - in the form of an angle of 80 degrees;

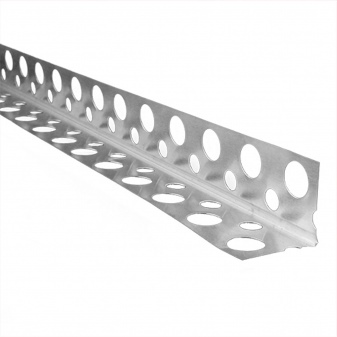

- We also note such an advantage of an aluminum part as 5-mm holes on its shelves - a perforated corner profile guarantees strong adhesion to plasterboard surfaces, due to the fact that the building mixture gets into them during plastering.

Other types of reinforcing squares

- For drywall, a galvanized perforated corner is often used, its purpose is to strengthen and protect the outer corners. With its help, even corners are formed, moreover, in case of significant damage, they can be restored later. Reinforcement of corners is recommended by means of parts with a height of 20x20 mm, 25x25 mm, 31x31mm, 35x35 mm.

- A protective PU-profile made of galvanized steel with a height of 20x20 mm and 25x25 mm is installed on the outer corners of partitions made of plasterboard sheets, it reaches 3 m in length.

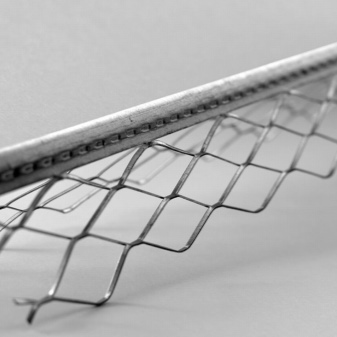

- To eliminate irregularities in residential premises, it is customary to use a metal plaster type of parts - a mesh profile, which helps to strengthen the walls and align them. It is made of steel and helps to form a reliable corner edge due to its high rigidity and anti-corrosion zinc coating.

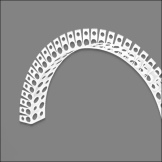

- For arched structures, he recommends choosing a flexible plastic corner - it prevents mechanical destruction and chips of the outer corners of the structure. In the areas where the ceilings of window and door openings are adjacent to the surfaces of walls and corners of buildings, this detail protects the plaster layer from cracking.

How to fix it?

The corner product for the safety of the joint zone is installed when laying surfaces. The most important point is the even fixing of the part. Before installation, it is necessary to apply a putty or plaster solution to the corner, which will independently penetrate into the perforation. As a rule, this is sufficient to firmly fix the part, and there is no need to grout the element. However, some types of squares come with a special adhesive to speed up the installation process.

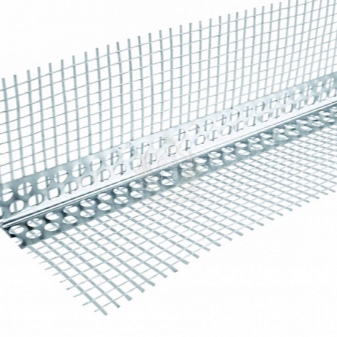

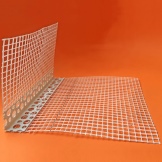

The PVC front corner with a reinforcing mesh has its own installation features - it must be laid on the already applied construction adhesive, placed on the surface of the insulating layer. Having pressed it into the glue base, then you need to level the part with a level, and then immerse the mesh there, and then remove the excess glue with a trowel.

Professionals believe that it is better to install plastic corners, as they are more resistant to any damage, but in this case, a thicker layer of plaster layer will be needed.

Corner protection profile - a useful tool that not only makes corners and edges straightbut also provides a secure, durable grip on surfaces, smoothing out any unwanted differences.

The comment was sent successfully.