All about T-shaped metal profiles

When erecting a variety of frame structures, a large number of special profiles are used. They allow you to provide a more reliable fixation and hide all the flaws. A large number of these building parts are currently being produced. Today we will talk about T-shaped profiles, their main features, as well as what materials they can be made from.

Description

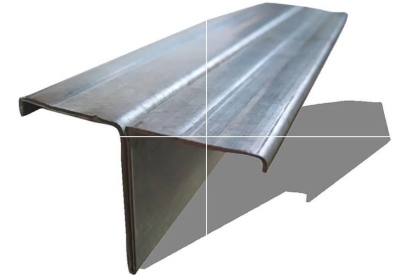

T-shaped building profiles can be used to create a wide variety of structures, including T-beams, foundations for flooring... These devices, as a rule, are made from various metals, which are carefully processed and coated with special protective compounds.

Such models of iron profiles allow you to form the most reliable and durable connections. All of them boast excellent strength and low weight, which makes installation technology quick and easy.

Some important requirements are imposed on these metal T-structures in the manufacturing process. So, they must withstand maximum mechanical loads and at the same time neither break nor deform, have sufficient rigidity with a relatively small mass.

All these metal profiles are produced by hot and cold rolling of sheet or roll material or by welding of processed metal strips.

Species overview

Currently, manufacturers produce a wide variety of models of such connecting profiles. Let's consider several main classifications separately.

By material

Most often, several materials are used to make T-shaped products.

-

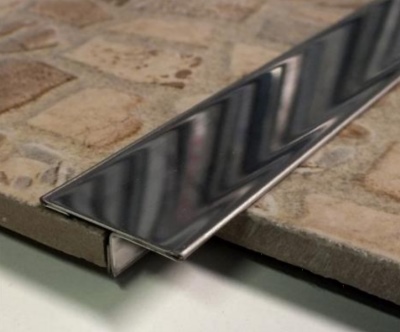

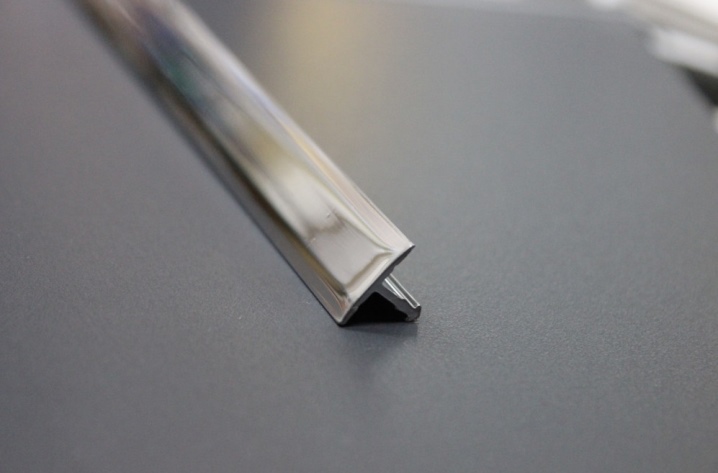

Stainless steel... It is considered the most durable and wear-resistant. This metal practically does not corrode, it will retain its appearance for as long as possible. Stainless steel will not lose its properties when exposed to various aggressive chemical substances and water. In addition, such a steel base is often used to create profiles, which will later be used to create frame structures for industrial buildings.

-

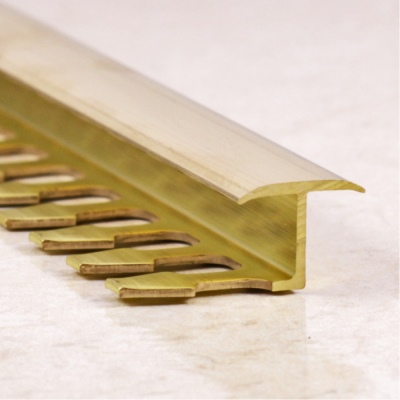

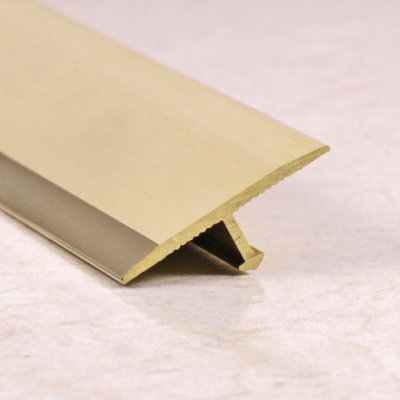

Brass... This type of metal has an attractive appearance. It has an unusual golden color, so it can look great with various indoor finishes. Brass profiles are most often made with a galvanized coating; they boast good resistance to moisture and temperature extremes. Sometimes they are used when decorating a bathroom in a house.

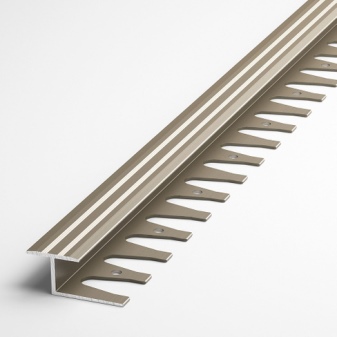

- Aluminum... This metal for the production of profiles is an absolutely environmentally friendly product. It is particularly resistant to corrosion, moisture and temperature changes. In addition, aluminum is lightweight, which makes working with it as easy and fast as possible. Profiles made from this metal material are relatively low cost. But at the same time they are quite strong, durable and wear-resistant.

To size

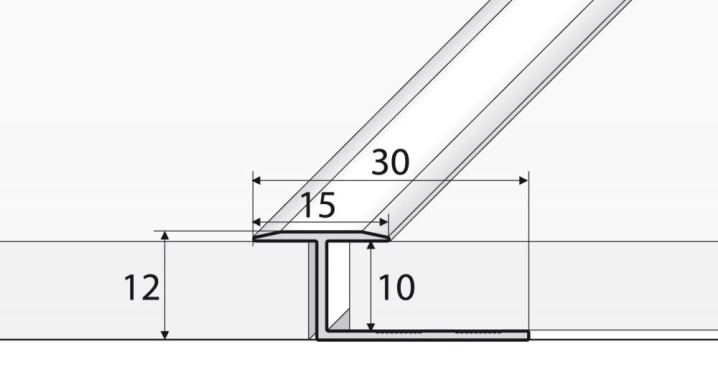

T-shaped profiles can be of a wide variety of sizes. All permissible dimensional values can be found in GOST 7511-73. The height of such products can vary from 15 to 50 mm. Their thickness can be equal to 3, 4, 5, 7, 8, 9, 10 mm.

By processing methods

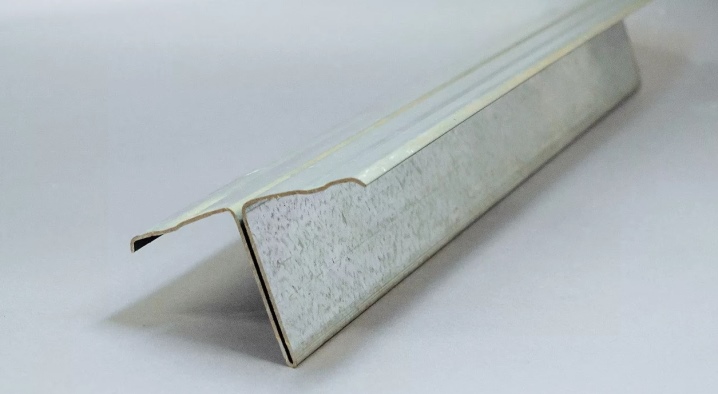

The metal used to make these building profiles can be processed in a variety of ways. The most popular option is considered zinc coating... It allows you to give structures an attractive appearance, make them much more resistant and durable. Galvanized models, if necessary, can be painted in a variety of colors.

In addition, this type of coating can easily withstand stretching and bending. This application prevents the formation of a corrosive layer. It should be noted that the coating is quite cheap due to the low cost of zinc, so profiles processed in this way will be affordable for any buyer.

Chrome plated is also a fairly common option. It is obtained by diffusion saturation of the surface with chromium. As a result, the design acquires a mirror finish.

Metal processing with chrome allows making it as resistant as possible to various adverse factors, including corrosion. Moreover, the products will become especially resistant to atmospheric influences.

Sometimes a special thermal diffusion deposition. In this case, zinc is also taken as a basis. At the same time, it will provide maximum protection for various metals. Such processing will make the product resistant to corrosion, mechanical damage and deformation.

Thermal diffusion coating layer must have the same thickness in all places, even when it comes to products with complex shapes and bends. In the course of long-term use, the coating will not peel off.

Sometimes a special phosphate coating... It is a phosphate salt application. It is she who forms the protective film on the connecting structures. This substance also prevents the formation of a corrosive layer. Most often, metal processed in this way is additionally coated with a paint and varnish composition to ensure maximum protection.

Sometimes they use processing with non-metallic coatings. First of all, paint and varnish compositions should be attributed to them. They contain special film-forming components, coloring pigments, special fillers and catalysts, solvents, plasticizers. These substances for metals allow you to protect their surface in various conditions, while giving a decorative design.

Such coatings include silicate enamels. These protective substances in the form of a powder or a special paste are applied in an even layer to the structure, and then heat-treated. After that, a thin protective layer forms on the surface of the products, which can protect against moisture, but at the same time it can crack under the influence of excessive shock loads.

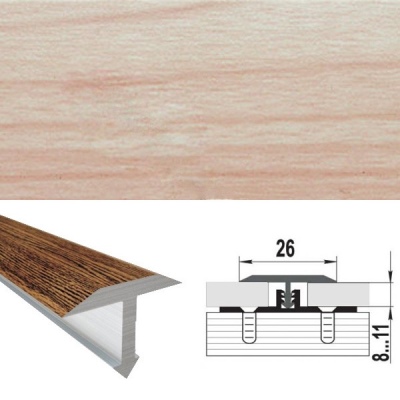

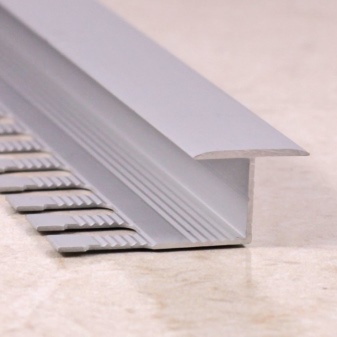

There is a special T-shaped model SP. These structures additionally have a small leg, while such models can be fixed between the floorboards, while decorating the coating.

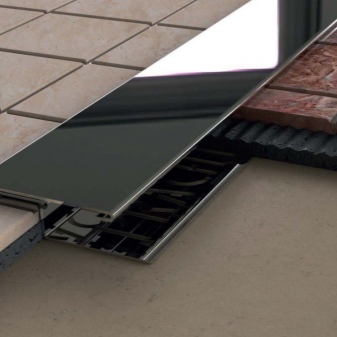

And also stand out SPA products. They have a docking groove, they are also mainly used when fixing floor material. The details will allow the tiles to neatly fit together. At the same time, they will completely close all the gaps and make the overall design much more beautiful.

Applications

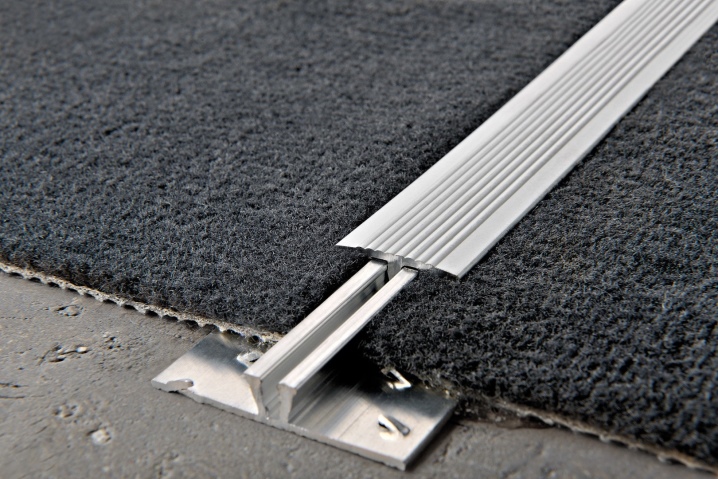

T-shaped profiles have found their application in various areas of construction. So, they are often used when laying flooring, especially laminate and tiles. The designs allow you to create a fairly solid foundation.

Today, special decorative T-shaped profiles are produced. They can neatly hide and decorate the joints. Such products are also used for laying floors. These designs are often created with a laminated application to imitate various types of wood or natural stone.

And also T-shaped patterns can be used to create ceiling systems. In this case, the cover will have an open frame. Moreover, products coated with protective enamel or powder paint are mainly used.

If you plan to make a suspended ceiling covering, then preference should be given to special transverse and bearing profiles. They will allow you to form a cellular surface, into which drywall and soundproofing boards will be installed in the future.

This type of profile can also be used in the construction of greenhouses and greenhouses. Indeed, with their help, you can easily fix sheet and panel building material. Metal structures will give such structures the required rigidity.

And also T-shaped parts have found their application in the creation of various ventilation systems, decorative design of sills, sometimes they are also used in monolithic construction.

The comment was sent successfully.