All about T-profiles

T-profile is a unique material with a wide range of uses. In this article, we will tell you how it looks and what it is made of, what its types are, how it is attached to the base. We will also draw your attention to the nuances of selection and fastening.

general description

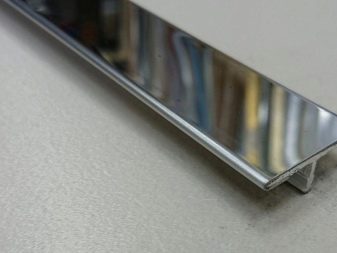

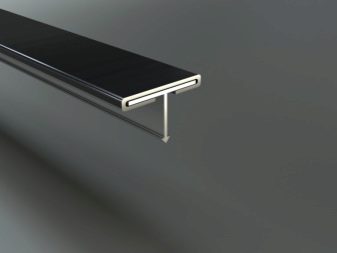

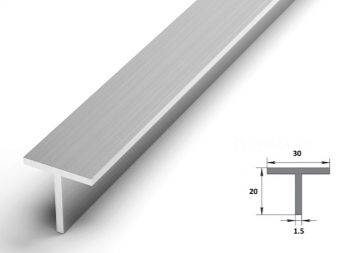

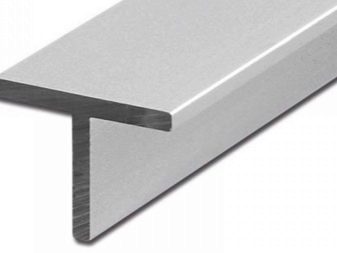

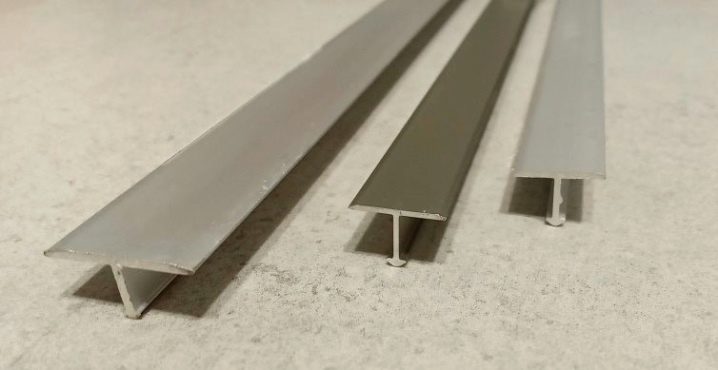

T-shaped profile (Tavr) - rolled metal products. The profile owes its name to the section in the form of the letter "T". This is a molded part with a constant cross-section and a transverse flange.

Visually, it looks like a long flat bar of a certain width with a vertical leg in the center. Manufacturers' parameters, shape, length and type of leg may vary. The general characteristic is sufficient rigidity.

The solid profile is durable and reliable. It is resistant to deformation and accidental mechanical stress. Due to its inertness to negative environmental factors, it does not rust and does not collapse due to temperature extremes.

It can be used outdoors and indoors. Depending on the variety, it is the main and decorative element of a particular design.

He has the optimal weight, plasticity, reasonable price. It is always available for sale. Differs in durability, can serve for decades.

It is characterized by precision in geometry and dimensions. Resistant to dynamic and static loads. It is structurally simple, has a different type of ignition, toxicity, smoke formation.

Varieties

T-shaped profiles can be classified according to different criteria. They differ in technology and production method, configuration, material of manufacture.

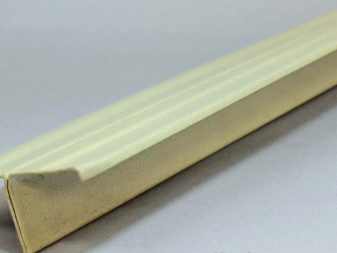

T-profiles are made from different raw materials. Based on the purpose, the guides can be wooden, vinyl, plastic, reinforced concrete and others.

At the same time, plastic, metal and their alloys are often used in mass production. Each type of planks has its own technical and operational characteristics.

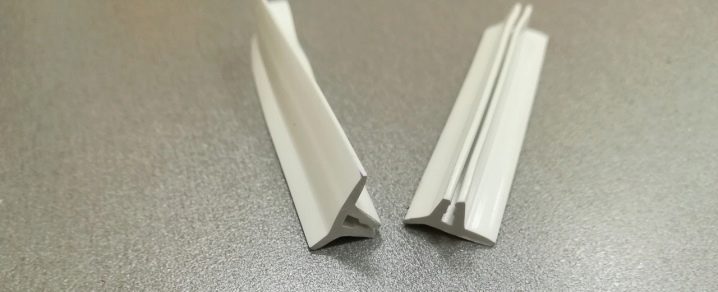

Plastic varieties are quite flexible and malleable. They are thinner than other analogs, have a lot of shades. They are in special consumer demand.

Metal options are produced by hot or cold rolling of steel (sheet, coil types). In addition, a steel strip welding method is used.

In addition to rough steel, stainless steel, guides are made from aluminum and copper alloys. The production technology involves surface treatment.

The profile can be galvanized, polished, polished, laminated, chrome-plated, enameled. Hot or cold galvanizing significantly improves the performance of products.

Aluminum varieties are anodized. As a result, their performance remains predictable. However, not all types of planks are subjected to this treatment.

Therefore, some varieties are designed for gentle indoor use. By means of others, elements of facades of structures and other structures are fastened.

Based on the width, there are 3 types of profiles: large, medium, small. By thickness, products are divided into 2 types: thin and thick. The parameters of the classic options are up to 0.4 cm and more.

The thickness of large ones reaches 15 cm. Due to their strength, reliable frame metal structures and tiled floors are obtained.

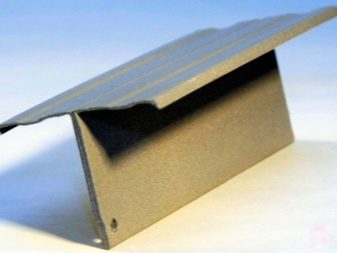

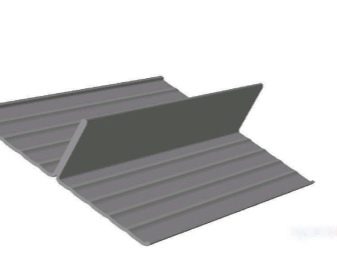

By design, profiles are main and transverse. The former are variants of the carrier base, the latter are used to produce modules of the required parameters.Based on this, the length of the main ones is 3.6 m, the transverse ones are 0.6 and 1.2 m.

The color of the profiles varies. Universal shades - white and metallic matt, matt silver, black. Decorative T-profile is painted in chrome, wood, gold, bronze.

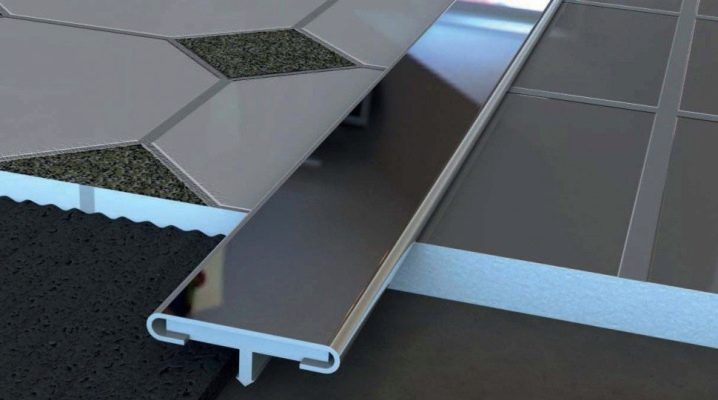

It can be load-bearing, front, decorative, docking. The latter varieties are connected by tiled elements. With their help, base defects are masked. They make the appearance aesthetic and complete.

For example, a docking profile with a T-shaped section is needed for the seam finishing of the table top. The flexible analogue is used in furniture production.

In addition to connecting, brands are decorative and protective and compensatory. The first to complete the joining of 2 coatings of different types. They define the boundaries of the different claddings.

Compensatory analogs are responsible for compensating for the expansion of the building material associated with a temperature difference.

Applications

The range of operation of T-profiles is extensive. They are used in the manufacture of furniture, windows, and various partitions. In addition to aircraft construction, they are used in construction.

The T-shaped profile is indispensable in the manufacture of suspension systems with an open metal frame. It is used for cassette ceilings, Grilyato and Armstrong structures.

It has found application in the manufacture of various types of structures from plasterboard and minerals. The interior design of offices, catering outlets, healthcare institutions, residential and industrial premises cannot do without it.

It is bought for repair and decoration of shops, shopping and entertainment centers. It is used in the construction of large facilities (airports, bus and railway stations, educational institutions).

Besides, T-profile is necessary in the construction of swings, fences, gazebos, terraces... It is used by various transport companies, as well as in shipping and mechanical engineering.

It is bought for the construction of a ventilated facade, installation of tiles, laying laminate. He found application in electrical engineering. Aluminum conducts current, so this type of profile is needed for the manufacture of various equipment.

In addition to electrical communications, it is used in everyday life, in small businesses. A classic example is in landscape design. No less common use is in greenhouse structures, for which varieties of 10x10 cm are purchased.

Domestic use - the creation of flower greenhouses, for which they take options with a section of 18x15 mm and a thickness of 0.3 cm. Balconies and loggias are built using universal modifications.

Tavras are needed for glazing facades, manufacturing shelving structures, shelves, railings.

Selection Tips

When choosing a T-shaped profile, a number of nuances are taken into account. In this case, they proceed from the characteristics, performance, prices. WITHcost for 1 piece. depends on various factors: material thickness, stiffener height.

The profile type is indicated on the marking in the form of letters and numbers. You need to choose the right type of material in order to avoid buying unusable building materials.

For example, AD31 – AD35 - types of construction purposes used in complex systems. They are especially durable and resistant to various influences.

Steel options are developed in accordance with GOST 22233-2001 (GOST 8617-81). With their help, they carry out external finishing, engineering communications.

When buying, perform the necessary calculations taking into account the total number and size of the profile. Large shelves are more than 30 cm, medium ones vary from 5-30 cm, small ones do not exceed 5 cm.

For monolithic construction, large rolled metal is taken. If you plan to install tiled floors, vertical slabs and frames, this is what you need.

To create cellular systems and decorate joints, small analogs are bought. They are also needed if they assemble movable systems for transforming furniture.

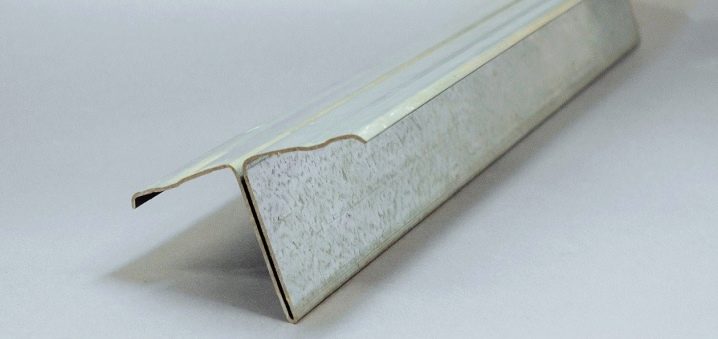

Particular attention is paid to the shape of the profile. In the classic version, the lengths of the base and the crossbar are equal.For other types, the base may have folds.

On sale there are options with grooves. In this case, the length of the cross section is not equal to the shelf itself. The stand can be thin, thick, regular, round.

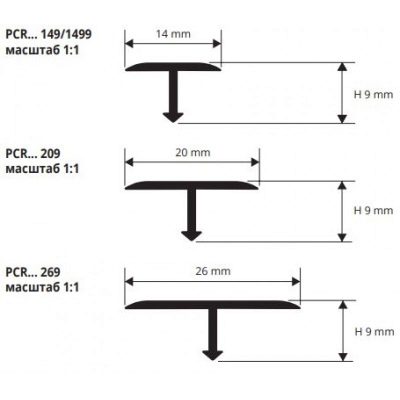

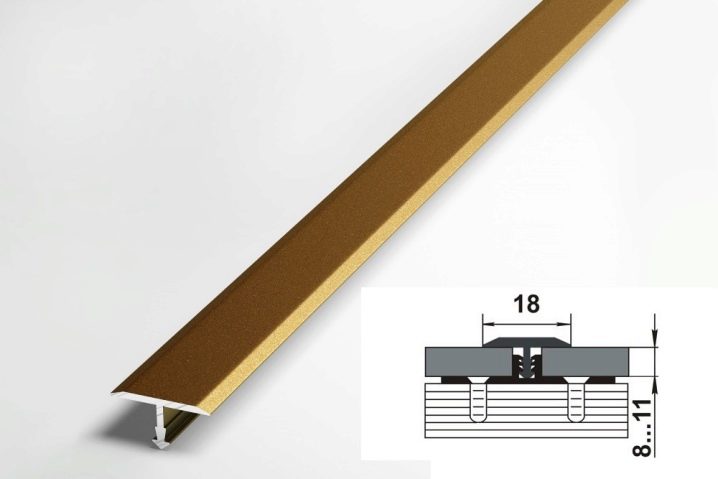

Shelf bearing modifications have a length of 3.6-3.7 m, transverse - 0.6 m.As a decorative jointing, options with parameters 1.5 and 2.4 cm with a rack height of 3.8 cm are suitable.

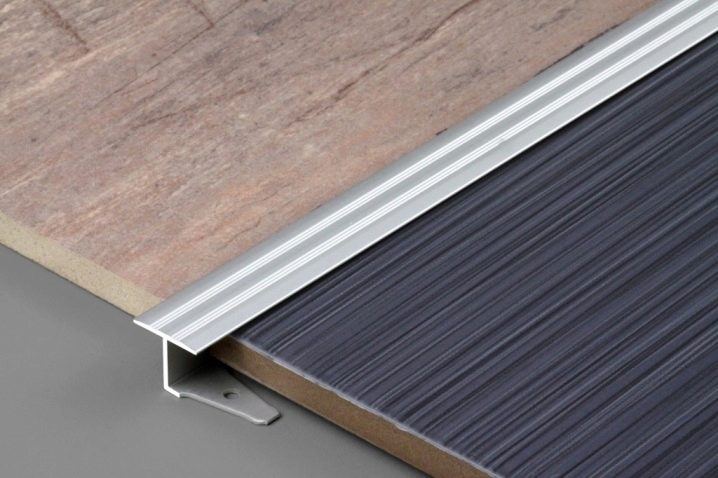

The laminated sill has a rack height of 9 or 10 mm; for chipboard, they buy options with a parameter of 1.7 cm. The length of aluminum modifications is 2.7 m. With their help, linear and curved single-level surfaces are joined.

The choice of the width of the T-bars for finishing the ceilings is not accidental. It determines not only strength, but also visual perception. The wider the visible part of decorative models, the more expressive the constructiveness. In small rooms, options with a smaller thickness are needed.

When buying aluminum brands, it is worth considering: the technical characteristics of the alloy options are better than those of pure aluminum. In this case, it is important to proceed from the properties, choosing between typical and enhanced types. Hardened modifications are more reliable.

They are also defined with the type of surface. Somewhere you need a profile without processing. In other cases, they buy models with heat treatment (for example, aged).

What do you need for installation?

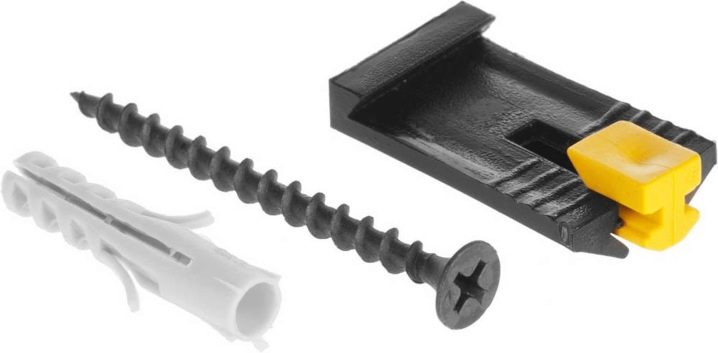

Based on the type of brand, it can be supplied with a different type of fastening. Some modifications are fixed with an adhesive or dowels.

This is how decorative varieties are established. They are inserted into the gap between the 2nd materials, and then fixed with glue. Liquid nails are poured into the holes of the mounted floors.

The best types of profile for gluing are stainless steel and brass versions. Both materials will look aesthetically pleasing for a long time, so the most durable and wear-resistant brand is chosen.

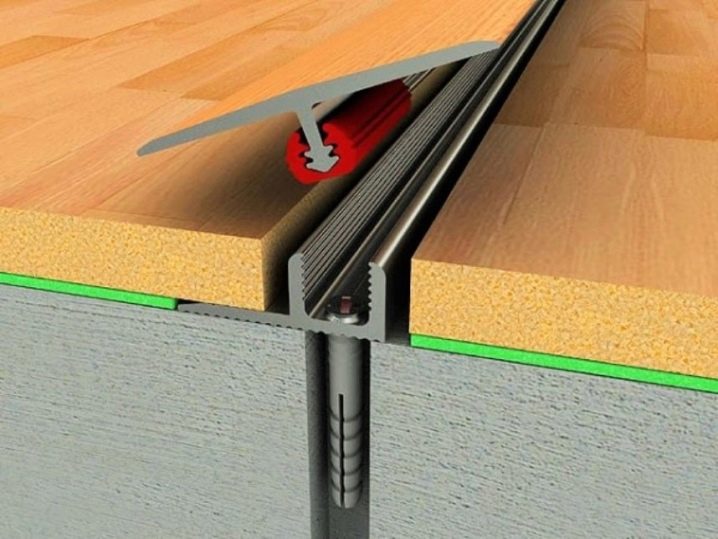

When fastening the latch without glue, use special strips in the shape of the letter "U". The latter are fixed to the floor base with screws. The hole spacing is 15 cm.

After the mounting bracket is installed, they are engaged in the placement of the brand. According to the generally accepted scheme, it is inserted into the grooves of the auxiliary strip.

The chips formed during operation are removed with a vacuum cleaner. This type of installation is more practical and is suitable for arranging different types of floor coverings.

Professional fasteners not only simplify installation, but can also replace the threshold. They are convenient in that, if there is a need for repair, they can easily dismantle the sills.

This happens when the brand has lost its aesthetics and is pretty worn out. In comparison with glue, fasteners provide for pulling out the old threshold and replacing it with a new one.

These mounts are installed once. They serve until the entire floor is dismantled. Only the upper part changes. Moreover, the installation of the base is carried out before laying the cladding.

When the tiles are already laid, the type of fastening is different. The latch is fixed with tiled mortar.

Installation on dowels is used when working with laminate. In this case, the installation is carried out after the material has been cladding. Before that, holes are created in the floor.

Then the dowels are put on a part of the arrow-shaped threshold, moved apart to the length of the holes. Then the profile is upset until it comes into contact with the floor. The grip will press the material as tightly as possible to the base.

The comment was sent successfully.