All about docking profiles

Docking profiles - aluminum and flexible for the floor, liquid for linoleum and chipboard - allow you to harmoniously arrange the transition between materials when installing floor coverings. They are available in various design options, shades, and do not require special efforts for fastening. When planning the use of materials of different structure and texture in finishing the floor, you should carefully consider which profiles will be used when they are joined in the interior.

Description and purpose

Docking profiles - special strips used in the installation of floor coverings for sealing and insulating joints between materials. With the growing popularity of combined design projects, it became necessary to solve problems that were simply not relevant earlier. For example, to connect laminate and tiles, other panels, parquet and porcelain stoneware, special elements are used at the boundaries of the premises, replacing the usual thresholds. In addition, profiles are needed for linoleum - where 2 sheets of material are connected, it is almost impossible to fasten them without creating a gap.

The main difficulties in the installation of coatings of different thicknesses are as follows.

- Mismatch of heights... For joining floor tiles with parquet or parquet board, the laminate has to adjust the difference of 2-5 mm, which arises due to the peculiarities of laying the coatings.

- Offset elements... For panels or drywall that are not rigidly attached, this is the norm. Laminate is also able to move vertically relative to the substrate.

The connection of coverings with different fastening methods (rigid fixation and movable) requires the use of special docking strips. They are produced separately for linoleum, laminated chipboard, fiberboard, chipboard, and other materials.

Depending on the purpose, the depth of the masked gaps, a suitable profile option is selected.

Docking profiles do not only play a decorative role. They have a very obvious functional purpose. This product category is available in several designs.

- Classic straight... Such profiles can withstand significant operational and mechanical loads. Stacked in only one plane. Rigid metal strips are most commonly used.

- Leveling... For these profiles, the structure looks like a corner with sides lying in different planes. The best option is selected based on the height difference. The strips are fastened with self-tapping screws, sometimes elastic gaskets are additionally used.

- Connecting decorative... Such profiles are more like sills. They are the widest, have an external decorative coating, provide simultaneous joining of floor sections of different heights and eliminate a not too aesthetic seam.

- Finishing or finishing... They are mounted along the wall where a small gap needs to be bridged. Such profiles are good substitutes for skirting boards, they can have a plastic or metal base.

When selecting suitable docking strips, it is imperative to take into account their purpose, application features. Some decorative options require a professional approach to installation.

The easiest way is to attach plastic profiles.

Varieties

There are several types of profiles used when joining dissimilar materials. Metal the docking material, most often aluminum, can have a width of 10 mm, 16 mm, 25 mm.It does not corrode, is lightweight and has a long service life. Where metal profiles are not used, they use plastic options - based on PVC, other polymers with sufficient strength and elasticity. All existing types of floor docking strips should be considered in more detail.

Liquid

A popular solution designed to connect linoleum canvases, as well as tiles and laminate with each other... The structure of the liquid profiles is an adhesive base mixed with small particles of cork. Such mixtures are used after laying the coatings, filling with them the gaps formed between different types of surfaces. After hardening, the excess glue remaining on the surface is simply cut off with a sharp knife blade.

A distinctive feature of liquid profiles is the ability to use them for curved connections.

Such dock sealers are delivered in packages of 0.5 l. The mixture hardening process lasts from 6 to 12 hours. It is introduced into the slots with a glue gun.

Flexible

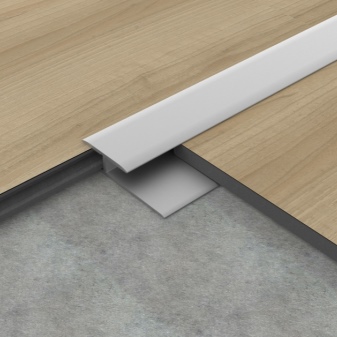

Profiles of this type made on the basis of PVC or rubber are used when joining coatings with uneven edges. This is the best option for curved joining of laminate and tile flooring. The profile is not afraid of operation in high humidity conditions, it easily accepts the desired bending angle. The standard dimensions of such elements are 36 mm in width and 4 mm in height, the surface has a semicircular shape.

Installation of flexible profiles is carried out in the process of laying the coverings. It is fixed in a special striker plate, providing a tight fixation without displacement. This solution is well suited for scratch sensitive coatings.

Hard

These are classic profiles for overlapping straight joints.... Such connecting strips are produced from durable and hard materials - wood, metal, PVC. Rigid profiles are used where it is necessary to provide increased strength, resistance of the joint to abrasion, mechanical or shock loads. They are less susceptible to warping during temperature changes, which makes it possible to decorate commercial or unheated premises.

Also, the distinctive features of such profiles include:

- versatility of installation;

- minimum requirements for the rigidity of coatings;

- long service life;

- attractive appearance;

- wide size range.

Aluminum docking structures are fixed to the floor surface self-tapping screws... Plastic and wood options are often simple paste in the joint, ensuring complete sealing of the seam.

In some cases, such planks are used as thresholds at the boundaries of the premises. In this case, the installation is carried out both flush with the floor, and with an elevation above it. The most budgetary solution in this case is a metal profile.

In terms of their cross section and appearance, such docking strips can be as follows.

- Brass T-shaped. The products are attractive in appearance and flexible enough to be used to form joints with different geometries. Brass is resistant to corrosion, may require periodic cleaning, and darkens over time.

- Brass Chrome Plated T-Shape... The products fit well with the high-tech aesthetics, combined with tile and laminate combinations. Such profiles are used only for straight-line installation.

- Aged brass... Made specifically for parquet and stone flooring. They look more respectable. To age the surface, the metal is annealed.

- Polished brass... Profiles with a golden sheen. This is a design solution for grandiose interiors. Marble and tile floors look good in this setting.

- Aluminum matt. A versatile option that is ideal for use with linoleum or laminate flooring.Aluminum can darken, is afraid of scratches. Such decorative strips are usually the narrowest, about 1 cm wide.

- PVC. Polymer T-section profiles are quite popular, they are available in a monochromatic design or with imitation of wood, they are easily matched to the decor of the floor covering.

In addition to plastic and metal profiles, rigid cork expansion joints are also produced.... They are produced in the form of strips 0.9-3 m long, 15-22 mm thick, the width is determined by the dimensions of the gap. The material can be painted independently in any color, the tone can be fixed with polyurethane varnish. Cork expansion joints work well between ceramic tiles and laminates.

Mounting

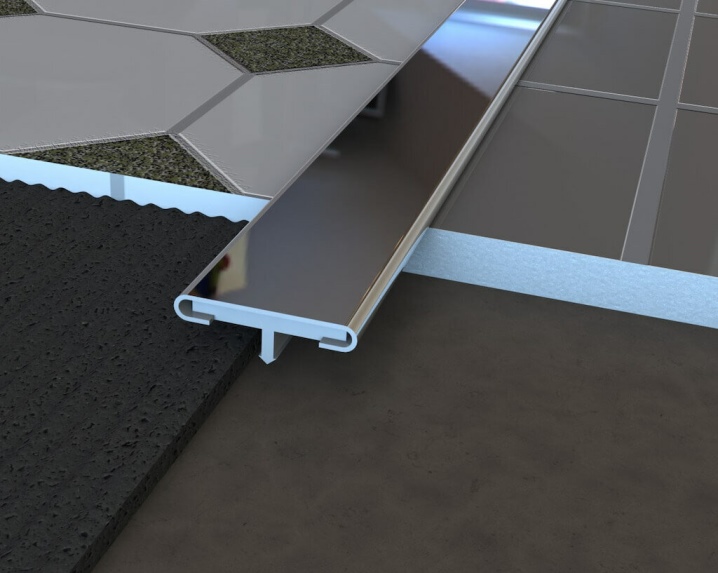

Most often, when installing floor coverings of different heights, T-shaped profiles are used, the striker for which (the embedded part) is installed under the joint, on the substrate. Most often, this solution is used at the border of the premises. It will be easier to correctly join the floor coverings with each other if you follow the detailed instructions.

- After completing the installation of the hard adhesive part of the covering, attach a plastic insert to the substrate. The width of the striker is selected based on the dimensions of the gap. The mortgage can be laid in one section or divided into blocks.

- Lay the cover with a movable base. Measure the length of the resulting gap.

- Cut the profile to the specified size. Better to use a mobile circular saw.

- Try on the docking bar, if necessary, adjust it to fit the features of the joint by cutting one of the edges.

- Remove the plastic tape plug from the embedded part. It is needed so that the inlet groove does not get clogged during the installation stage.

- Insert the docking profile into the embedded part at an angle of about 20 degrees, slightly squeeze, place in the place designated for it. Make sure the element is fully seated in the mount. Go over its entire surface with a mallet, after placing felt or soft textiles.

When using plastic profiles, it is important to remember that these elements are not reusable. Any errors during installation will lead to the fact that the embedded part and the bar itself will have to be changed. When using a flexible profile, the mating part is fixed after laying the coverings, without forming height differences. You can remove the ledge by removing the backing, simply by trimming it.

When choosing a docking bar, it is important to pay attention to its maximum bending level.

How to install the docking profile, see below.

The comment was sent successfully.