Features of connecting profiles

Polycarbonate sheets cannot be joined perfectly, so that not a single drop of rain seeps through such a shelter under a roof mounted in this way. An exception would be steeper slopes - and only for solid polycarbonate, but such a connection looks unaesthetic, and PC overrun is inevitable.

But for flat slate, you cannot use a plastic H-element. The reason is insufficient strength, fragility of such a connection. Even when the slate is drilled on the roof and attached to it with self-tapping screws with gaskets made of wear-resistant high-quality rubber, the forces acting on the polymer profile cause its premature failure, since the low density of building materials is rarely fully combined with their long-term reliability. To connect slate and smooth (not profiled) metal sheet, it is better to use an aluminum or steel galvanized / stainless steel H-profile.

What it is?

The connecting profile for polycarbonate serves as a joint border located between the sheets. This is an elongated bar with a certain structure inside, most often an H-shaped component. It serves for joining PC sheets both during the construction of a greenhouse or a greenhouse, and during the construction (floor) of a transparent roof covering, an internal wall (in a building, a private house) partitions. H-profile is an almost ideal additional element connecting wall panels.

Slate, being made of artificial stone, is a heavy material, which puts it on a par with steel in weight.

Without a profile, even straight and precisely cut joints become a place where dirt gets along with moisture. This is due to square cells that are parallel to each other. If on dark polycarbonate such a phenomenon is not particularly noticeable, then on light polycarbonate this dirt immediately appears even against the background of diffused light.

It is difficult to remove dirt from the inside - narrow gaps make this process difficult.

The tightness when using the butt profile is significantly improved. This effect is necessary in greenhouses and greenhouses, where excess heat loss will make the microclimate in such a structure more severe and changeable. And the protective layer, which prevents the solar ultraviolet light from destroying the profile parts, will allow them to last up to 20 years - without the need for replacement. The plastic docking profile is easy to install and remove - even one person can handle this task.

Views

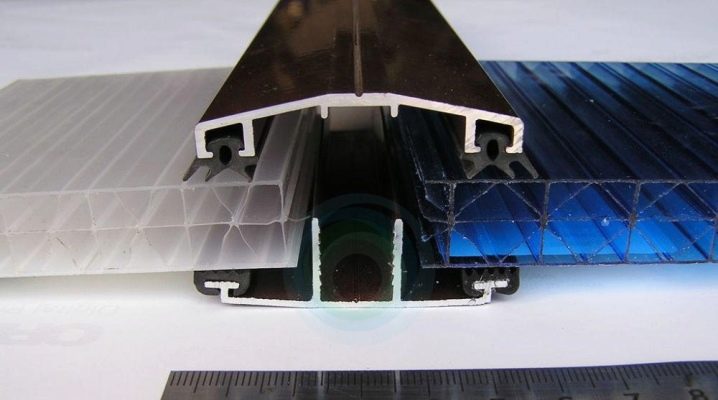

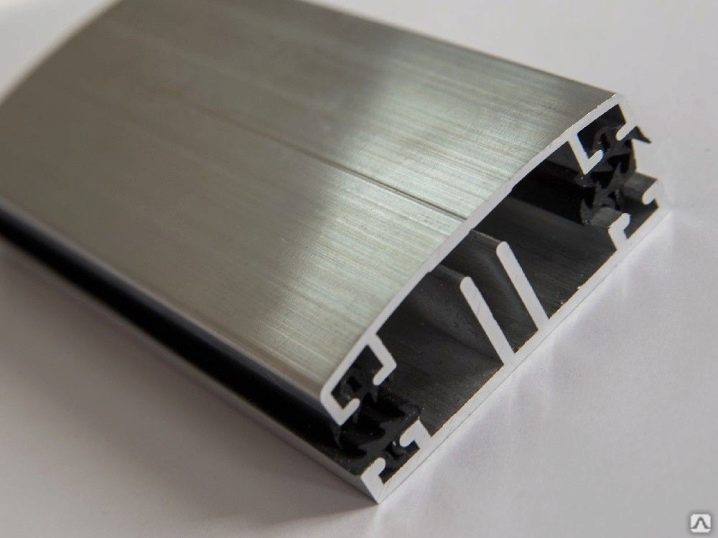

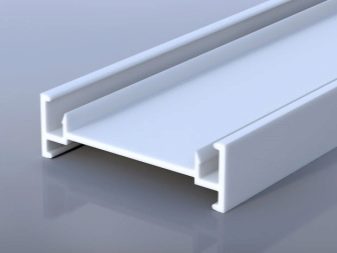

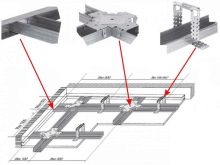

PVC profile in the form of H-structure - the simplest and cheapest option. PVC plastic does not support self-combustion, which meets the minimum fire requirements for such a roof (or ceiling). Docking of polycarbonate sheets is carried out by means of (non) detachable, corner and silicone components. The latter is an adhesive composition, not a profile. The main components of the joints are plastic and aluminum. When joining, the sheets are fixed with self-tapping screws, which are supplemented with heat shrink washers. Difficult and expensive tools are not required here.

All you need is a hacksaw, a grinder, a drill, a screwdriver, a hammer (you can use a rubber one) and a universal screwdriver with attachments. The assembly takes place on a smooth platform. Do not damage the material.

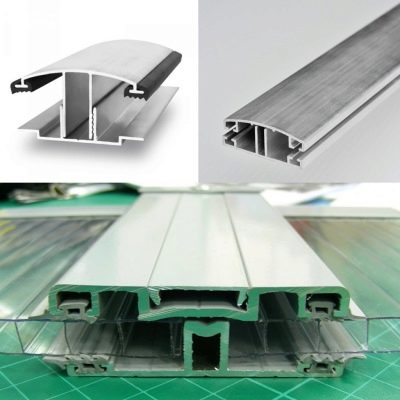

In the case of using a one-piece (the marker on the sheet is marked with the abbreviation HP), the sheets are inserted into the grooves of the strip, placed on it from the sides.Self-tapping screws are screwed in along the centerline of the central groove between the walls to the depth of the crate - the minimum insertion depth is 0.5 cm.To reliably connect the components, use a 2-3 mm gap between the end face and the surface of another component that softens temperature fluctuations. The fixed profile is fully suitable for lining walls with laminated chipboard, plywood. Its counterpart - aluminum and steel profiles - are used on the floor, and also connect materials such as plexiglass, solid PC. It is also used for fiberboard skin (a kind of apron), hardboard or thin (up to a centimeter in thickness) chipboard.

Using a split profile, the sheets on the arches are connected together. The upper part fits into the lower one - a kind of latch is formed.

The corner profile is used on polycarbonate with a complicated relief. The essence of its use is the formation of an angle of 90-150 ° between the overlap slopes and forms an element resembling its ridge. It is produced in the form of split and one-piece composite profiles. The sides of the ridge are equipped with a locking component with a height of 4 cm. Temperature fluctuations do not lead to bending and stretching of the PC sheets. Connector color - black, dark and light shades. Profiles of size 6, 3, 8, 4, 10, 16 mm are common, but the range of their values, covering the thickness of the connector and the depth of the grooves, is very wide.

Mounting

Instructions for connecting polycarbonate with plastic profile pieces are as follows.

-

Attach the main part of the profile to the supporting frame using self-tapping screws, passing them through the center line. Drilling holes for self-tapping screws will be required - as a rule, 1 mm less than the threaded diameter of these hardware.

-

Place the PC sheets in the side grooves.

-

Install the latching part on top - it fits into the base.

Check that all latches are engaged. Sheets and profile are installed.

The comment was sent successfully.