All about the C-profile

This article explains everything about the C-profile. The types of metal profiles are characterized, including aluminum, galvanized and steel profiles 41x41, 41x21 and other sizes. The subtleties of the production of the mounting traverse in accordance with GOST and the possibilities of using this product are described.

Peculiarities

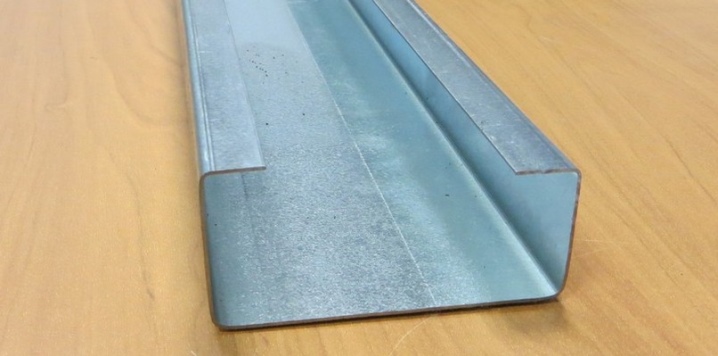

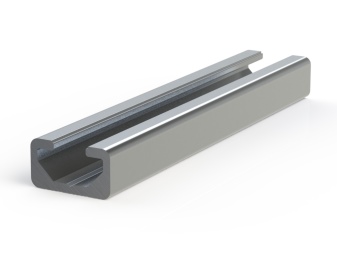

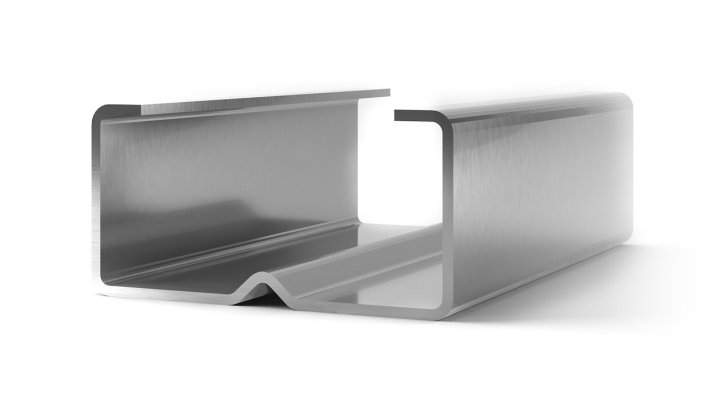

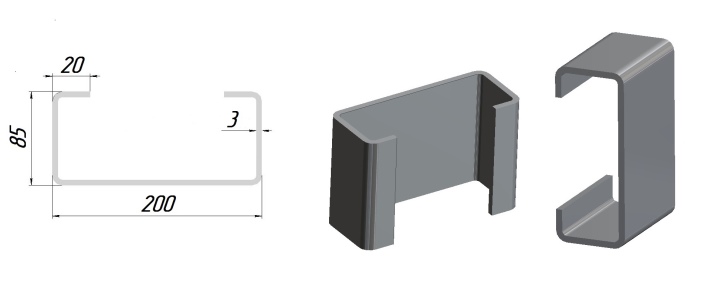

In a wide variety of frames and structures based on them, the C-shaped profile is constantly used. For its manufacture, shock-resistant steel grades, coated with a zinc layer, are usually taken. This solution guarantees optimal protection against moisture ingress and subsequent corrosion. The C-shaped execution of the profile is the most traditional. In most cases, the production of such a product is in limited quantities.

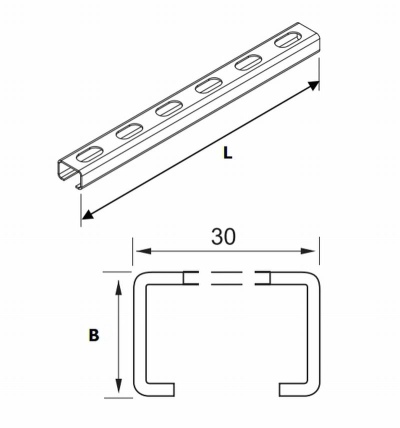

It is practiced to obtain both conventional and pierced products. Perforation makes finished models lighter, but reduces their mechanical stability.

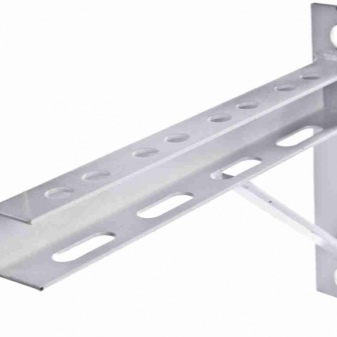

In favor of a profile with punches, excellent heat retention, a high level of sound insulation testifies. And, importantly, it is possible to effectively contain the propagation of vibration. A well thought-out design allows to ensure perfection and high mechanical reliability of the mounting crosshead, it can be mounted with a step of 3 m.

Regulatory requirements provide for the ability to operate such products in a wide variety of temperature conditions. Since many holes are punched, it is guaranteed to be used on a wide variety of sites during installation and repair work. Fastening to a wide variety of materials: concrete, steel and wood. For fixing, you can take:

-

nuts;

-

anchor elements;

-

brackets;

-

bolts.

In the manufacture of four-support traverses, the standards of GOST 18779-80 are used. The standard standardizes, among other things, the mass of specific products. Their typical dimensions are also strictly regulated. For the production of a C-shaped profile of the universal category, it is required to comply with the norms of another GOST - 8282-83. The standard clearly specifies the main assortment of such products, regardless of the type of metal used.

For the manufacture of profile structures of this kind, you will need:

-

machine for unwinding steel coils;

-

the mill on which the metal itself is bent;

-

feeder;

-

a device that receives finished products;

-

industrial-grade scissors (all other cutting options do not work very well in real production).

The sequence of manipulations is approximately as follows:

-

unwinding of coiled steel;

-

promoting it to a continuously and cyclically operating mill;

-

as needed - a combination of molding with the application of thermal strips;

-

cutting according to the initially set length;

-

warehousing and preparation for shipment.

Views

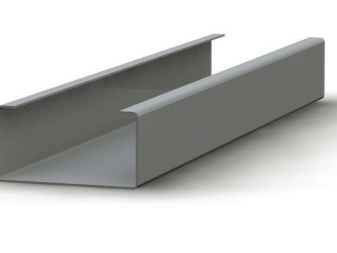

Galvanized steel profile is not the only option. A solid competition for it can be a product obtained from aluminum alloys. Aluminum is slightly more expensive than steel, but it also lasts much longer. Under conditions when a steel element will work for up to 10 years, its aluminum counterpart will have twice the ability to withstand daily loads. This even applies to situations with systematic mechanical stress.

Aluminum structures are completely protected from corrosion, they are not subject to temperature fluctuations and can be safely used in severe humidity.

Steel, although harder, needs careful handling. Roller fasteners can be hidden inside aluminum structures, which is especially attractive in furniture production. You can also add vertical inserts from different materials. The rollers slide silently without causing any inconvenience. Thus, even fears about the high cost of aluminum are not justified at all.

But choosing the type of metallic materials isn't everything. It is also important to pay attention to the processing method. So, along with simply bent, the cold-bent version is very widely used. Traditional hot rolled products are more ductile and easier to process, however, pronounced dross may appear on its surface.

The specific nuances of hot working do not allow to guarantee complete uniformity of the produced web. The surface will be rough. However, hot-rolled metal is less susceptible to corrosion. Only an additional layer of zinc can increase the corrosion resistance of the galvanized product. Cold rolled products can be quite thin and have a heightened aesthetic appeal; precisely defined dimensions and strict geometric contours are always maintained.

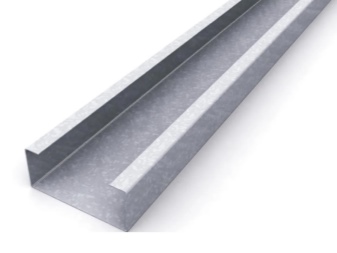

The double profile ensures maximum strength of the supporting elements. For its manufacture, high-quality steel is usually used not thinner than 2.5 mm. The typical length of such structures is up to 2 m. They are often taken to be mounted "in suspension". But the most common option is still an equal-flange profile, which is used in decoration and in the production of rectilinear objects.

Additionally, you may meet:

-

unequal;

-

profiled;

-

having perforation;

-

oblique;

-

rectangular;

-

fitting;

-

bulbous (characterized by rounded edges).

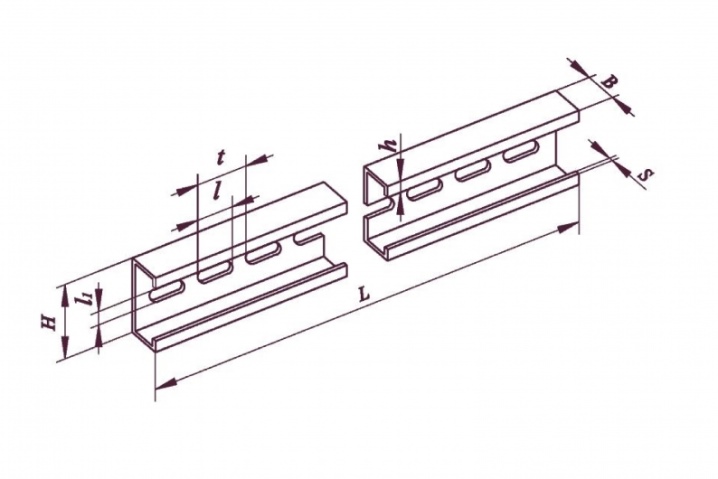

Dimensions (edit)

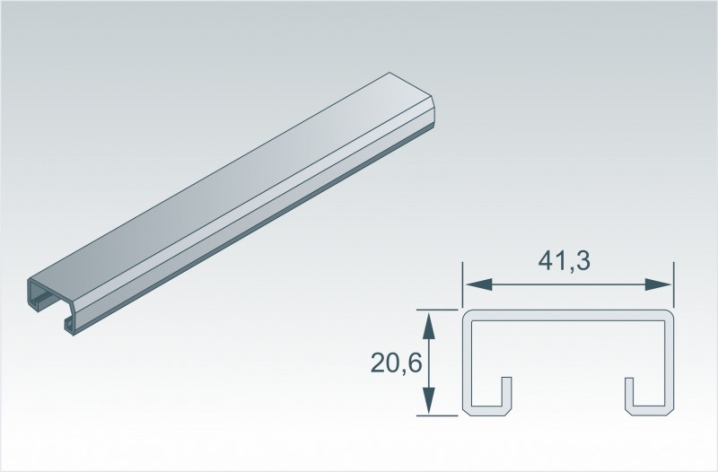

Designs with a size of 41x41, or rather, in most cases 41x41x3000 mm, are in demand. Their usual thickness is 2.5 mm. With such parameters, the profile is suitable for wiring in various power grids. Also, it is regularly bought by factories and agricultural organizations. But without problems, you can use such models in domestic conditions, and their small size allows you to put them in hard-to-reach places.

Quality profile 41x41x3000:

-

covered with a zinc layer;

-

can be mounted in any way;

-

serves for a long time.

For electrical work, a 41x21 profile or, more precisely, 41x21x3000 mm is also often used. Its standard thickness is usually up to 1.5 mm. Such a product is included in the popular B5 Combitech series. Its standard design is Sendzimir galvanized. Of course, there are other dimensional positions:

-

20x30;

-

30x30;

-

10x21;

-

18x30;

-

40x40 mm.

Scope of application

C-shaped profiles are in demand during construction:

-

warehouse;

-

hangar;

-

sliding gates;

-

car service stations;

-

private garages;

-

car wash complexes;

-

cottages;

-

small residential buildings.

But of course, the possibilities of its application do not end there. In some cases, the profile is used for plastic panels and plates. It is much more reliable and stable than wooden or plastic lathing. Such a product is capable of withstanding significant mechanical stress. An important advantage is the high speed of installation work, in skillful hands they are carried out literally in minutes.

Furniture metal profiles are also in demand. It is extremely reliable and works effectively in a wide variety of pieces of furniture.

Often, on this basis, stand-alone shelving systems or shelving systems that are part of a sliding wardrobe are made. An alternative option is the design of the frame of the pull-out drawers. Finally, C-shaped profiles can also be purchased by manufacturers of commercial furniture.

The comment was sent successfully.