Provedal aluminum profile review

Provedal manufactures a range of special aluminum profile systems that are used for glazing in various spaces. They are distinguished by availability, reliability, long service life and excellent appearance.

Peculiarities

These products were created about 15 years ago by the Spanish company Provedal Systemas and are also aluminum sliding structures. The manufacturer has made sure that the products are simple, reliable and of high quality. Moreover, they are suitable for warm regions, and in Russia they are used exclusively in cold glazing methods. Aluminum products have a number of advantages.

- Reliable sound insulation. Contributes to good protection against dust from the streets.

- Large assortment of varieties. So, quick-disassembly, sliding products are produced. There are also double-glazed windows.

- Low weight, and therefore they are installed even in old houses.

- Convenient sashes that do not take up much space - convenient for small balconies. The elements of the products move easily, contributing to an excellent air flow.

- Products take into account the most varied tastes and wishes of customers. Aluminum is plastic and makes it possible to easily implement various design ideas.

- Products are fireproof.

- They are cheap because they are economy class products.

- Long service life (more than 80 years), since aluminum is inert, and the painting is done reliably and with high quality.

- Versatile and versatile equipment. Triple glazed windows, as well as double and single glazing are produced. The latter options are suitable for arranging balconies. Residential apartments are equipped with triple and double glazing.

- Sliding products give more light. They are practical to use, but not without drawbacks. In severe cold weather, condensation remains on them, accumulating in the area of the rails and wheels. For this reason, windows sometimes jam. Such problems can be avoided with swing structures.

When purchasing sliding systems, you can choose the required number of sashes.

The structures are completed with high-quality auxiliary devices and provide high-quality heat engineering parameters.

In comparison with PVC products, constructions from the Provedal brand are more durable. The materials used in production make it possible to produce structures up to 6 m long, but metal-plastic ones are no longer than 2.7 m.

On loggias of significant size, the use of aluminum profiles allows you to reduce the number of vertical partitions. Due to this, the light transmittance of the windows increases.

The purchase of aluminum sliding structures occurs more often, since they do not open inside the premises, but move along the parapets, which makes it possible to use the balcony space more economically.

Besides, such designs give the least stress on the fittings, which last longer, which means that the cost of caring for the windows is reduced.

It is important to remember that aluminum products are environmentally friendly, they are not afraid of cold weather and sharp temperature fluctuations, since they almost do not expand, do not lead to deformation of windows.

In typical versions, these are products of light colors, covered with a polymer layer. For decorative coating, the extrusion method is used, for this reason the layer lasts for a long time. Its quality is not affected by precipitation and ultraviolet rays. Profile products are painted in any shades that are selected from a special RAL palette.

It is important to understand that profiles are produced by different factories, each of which is characterized by its own characteristics, but is guided by one corporate standard. Therefore, the choice of models is diverse. The high degree of practicality of these products and low prices make them popular.

Nevertheless, profiles have a number of negative qualities.

- Sliding options in the middle zones of Russia (and even more so in the northern ones) are used only for cold glazing methods.

- In addition to the low thermal insulation level, their weak tightness is also noted. In gusty winds with rains, water droplets can penetrate the balcony.

- It is not very convenient to put mosquito nets.

- In frosty weather, sometimes there are inconveniences with the opening of the valves due to their icing.

Nonetheless, these systems are of excellent quality for easy maintenance. You can equip non-standard windows: both in shape and size.

Applications

Profiles are used in 3 cases.

- When glazing balconies and loggias.

- When closing summer kitchen facilities at summer cottages, equipping verandas, arranging gazebos.

- When equipping entrance groups in suburban buildings. When arranging greenhouses and greenhouses.

In hot conditions, they will be a suitable replacement for double-glazed windows. At the dachas, glazed belvederes look great, where doors and window openings are closed with Provedal products. It is convenient to equip verandas and terraces with sliding devices. The profiles can be used to make assemblies for balcony cabinets.

Description of episodes

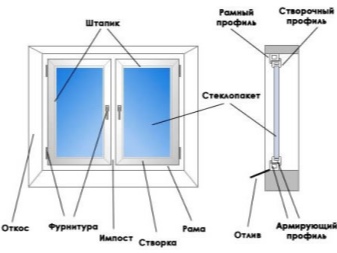

All presented models have their own technical characteristics. They are neatly contoured, smooth and well finished. The applied method of locking reinforcement gives them the greatest rigidity - deformations are extremely rare.

Users can select kits that include multiple chamber compartments. The installation width is 60 mm, the thickness of the insulating glass units is up to 16 mm.

Installation of windows with four compartments is allowed. In their typical versions, they are 60 mm wide with a rebate height of 24 mm. Reinforcement is made of galvanized steel. Products are made with two sealing circuits. Sliding options and double-glazed windows are painted in different shades.

Provedal also produces all kinds of modifications, taking into account the individual tastes of consumers.

Some of the most popular designs offered by the brand include:

- P400;

- C640.

P400 - devices with a width of 40 mm, where glasses with a thickness of 4–5 mm are installed. Glasses are used in tinted or energy-saving form, however, consumers often choose standard samples. This type of structure is available in a swing or blind version. The profile is also selected for equipping window openings of non-standard shapes (triangular, arched, etc.). Painted in different colors according to the RAL brochure.

C640 is a product with a sliding system. There is a two - or three-lane design. The width of the two-lane is 64 mm, where glasses of 4–5 mm thick are installed. But installation of double-glazed windows with a thickness of up to 16 mm is allowed. The production of translucent products of non-standard shapes with different sizes is also envisaged.

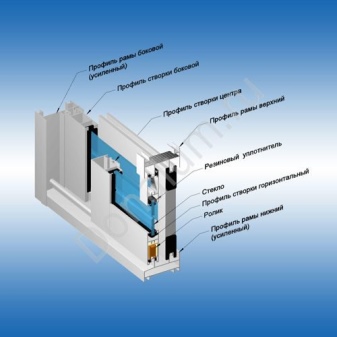

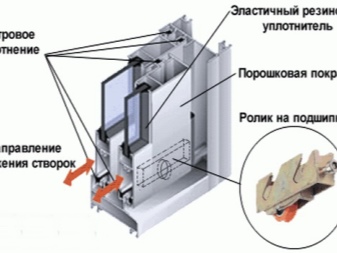

Provedal C640 profiles are produced in sliding versions, including a different number of leaves, with the number of sections from two to six. The sections are equipped with wheels, this is the distinctive feature of the products. For the movement of the sash guides are mounted.

The largest number of sections is present in three-strip products. With single glazing, the glass thickness is no more than 6 mm. Samples are fireproof, do not need special care, the sashes are simply wiped with detergents.

Product C640 is characterized by a significant light opening, soundproofing level - up to 10-12 dB.

Adapters and auxiliary profiles

Adapters and auxiliary profiles of various sizes include a wide range of accessories that can be purchased. For example:

- angles 90 and 135 degrees;

- ebb;

- adapters from Р400 to С640;

- I-beam 40 mm;

- adapters from 40 mm pipe;

- rectangle 60x40;

- the corner of the sliding "papamam", etc.

Fittings

As accessories (including accessories) are used:

- latches of various types;

- hinges for windows;

- assembly kits;

- rollers, crackers, seals, screws, felt, etc.

Installation and adjustment

Installation work consists of several stages. If you have a lack of experience in carrying out such actions, then it is better to invite the masters.

Initially, you should set the correct gap between the opening and the frames. Then correctly assemble the frame itself from an aluminum profile. Before starting work, check that you have all the necessary installation tools and necessary equipment.

The opening itself and the surface of the frame must be wiped dry. Especially carefully you need to collect frames and sashes in the winter.

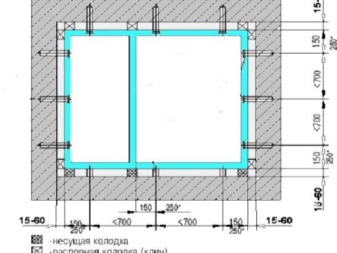

The site for future work is carefully cleaned of debris. The gaps between the opening and the frame on the side are 10-50 mm, below and above - 15-50 mm.

The installation procedure includes 8 steps.

- We install the supporting elements, placing them in the opening at the bottom.

- We make holes for self-tapping screws - in frame posts and in crossbars. Step - no more than 700 mm, diameter - 6 mm.

- We place the frame in the opening, controlling it vertically and horizontally. At the same time, we check everything by the level, we immediately correct mistakes.

- We put the top drain, placing it between the top of the plate and the frame, install the visor. We fix the ebb with self-tapping screws.

- We fix the frame with self-tapping screws.

- We close the gaps with polyurethane foam. After drying, cover it with a sealant, and then put the cover strip.

- We put the drain from the bottom, using self-tapping screws for its fastening. If it is located on top of the frame, then the joint must be filled with sealant.

- If necessary, we put the cover strips, placing them on the outside on the sides and at the top of the frame.

The assembly order must be adhered to. The process of arranging balconies and loggias can also be carried out with the installation of window sills. Wherein initially we select a corner of steel of the required dimensions, fix it, and then adjust the window sill to the frame. Next, we install the sash.

At the final stage, we put glass sheets in the sash that cannot be opened. Adjustable - all parts should be easy to open. Skews are unacceptable. We determine the need for drains ourselves. Platbands and other elements can be installed on request.

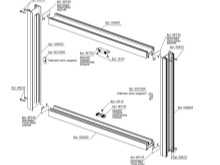

Samples of the C640 series have significant dimensions, and therefore the frame is delivered to the place of assembly in a disassembled state. It usually contains 4 elements, and for their assembly - 8 self-tapping screws.

The company produces boxes in three possible versions, and during assembly it is important not to confuse the top and bottom. To fasten the side elements to horizontally located frames, you will need self-tapping screws (at least two pieces by 1 angle).

To carry out the assembly, an assembly package is required, which is glued before starting the installation of the corners located at the ends.

When working with side frames, follow the rules.

- When installing the left sidewall, it is necessary to position the grooves of the hooks so that they look out.

- Installing the right side, the grooves are placed inside. There are some exceptions. So, when installing four-leaf products, the grooves-hooks are located outward in both versions.

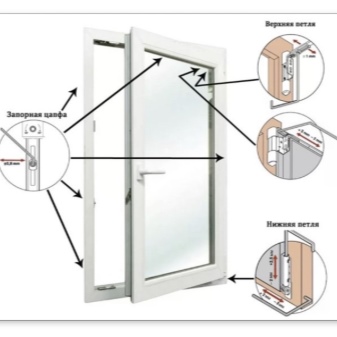

The installed elements are adjustable. Before the corners of the frames are fixed, hooks are placed for the tongues of the locks. First, they are lightly secured using a hex key. The remaining half of the latch is fixed after the distance for placing the tongue is determined. In the closed position after the installation of the leaves, the latches must fall "in the hooks".

Now let's move on to installing the frame. We place all the structural elements exactly, which we control with a plumb line, we also apply the level.

If such a need arises, then at this stage we strengthen not only the drain, but also the visor.

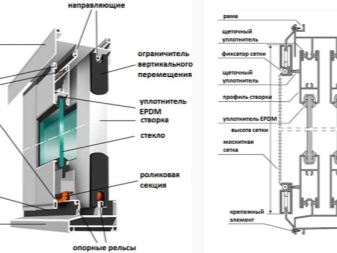

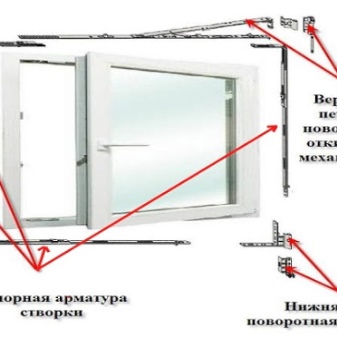

We proceed to the installation of the sashes. They are delivered pre-assembled to the site. For convenient opening of these elements, they are equipped with two rollers installed at the bottom, and when opening / closing the sash, they move along a groove in the frame.

We adjust them with a hex key (4 mm). The installation of the sashes is carried out with the frame already in the opening. But this must be done before filling with foam, since when it is inflated, the frame without flaps is easily deformed.

At the end of the next stage, we begin the adjustment process. With the help of a hex wrench, adjust the position of the rollers, if necessary. You can change the height of the hook, which is located above the locking tongue. Then it fits into the handle. We fix it with a hex wrench.

The work is done. Let's check the reliability of operation of the blockers to hold the shutters at the top. These parts are fixed with self-tapping screws and then closed with special decorative caps.

System seals are not only installed in the upper and lower parts, but also located between the rails.

An overview of the Provedal aluminum profile in the video below.

The comment was sent successfully.