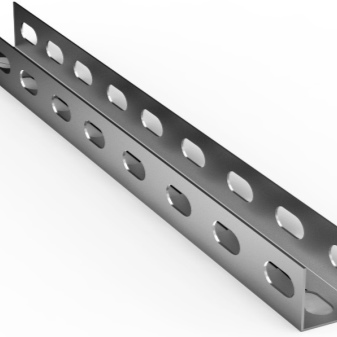

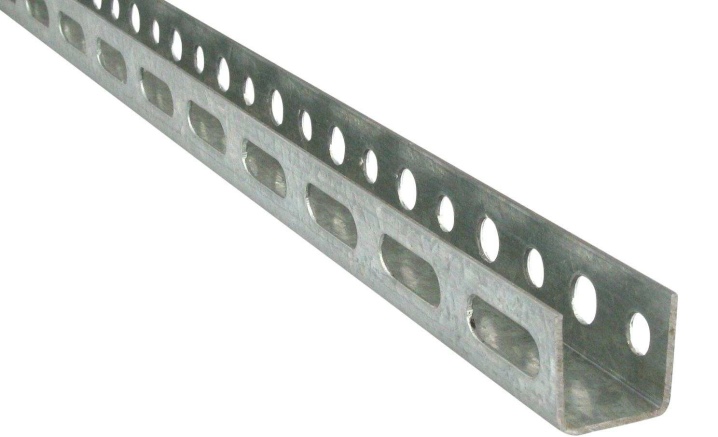

Perforated U-shaped profile: dimensions and application

The perforated U-shaped profile can be of various sizes. Its application is often different. It is imperative to figure out what are the features of galvanized mounting profiles 30x30x30x2 mm and 30x30x2000, 32x20x3000x2, 40x40 and other dimensional options.

Advantages and disadvantages

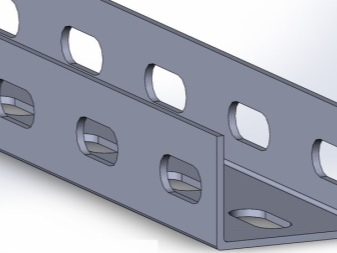

The perforated profile, made in the form of the letter "P", is quite common. Its use is quite common for both experienced professionals and novice builders (installers, repairmen).

The properties of such products are described as follows:

- suitability for multiple bending and unbending without compromising basic qualities;

- ease of fitting to pre-selected and calculated dimensions of the main structures;

- high inertness to chemical influences of the external environment;

- resistance to negative atmospheric factors;

- no need for welding (it is enough to fasten them with traditional bolts);

- cheapness;

- general ease of installation;

- suitability for long-term storage under normal conditions;

- the possibility of using in a very humid environment;

- absolute level of fire safety;

- no risk for humans, domestic animals and plants, for the external natural environment;

- long service life;

- reduction of labor intensity in comparison with competing solutions;

- increasing the bearing characteristics of mating structures;

- comparative ease.

But one should not think that such products are the best material in principle. He also has quite tangible weaknesses. For example, metal profiles under certain conditions can degrade and lose strength. And the fact that they are initially thin and light, sometimes also turns out to be a tangible disadvantage.

Fastening and hanging heavy objects on such a support is unacceptable: it is easily destroyed and loses its valuable characteristics.

The policies of individual manufacturers can also create problems. Rather, the fact that they do not live up to their own advertising promises. Often, protective coatings are not reliable enough and this can create very serious problems. Moreover, the type of profile elements strongly influences how much load they can carry. Variety selection mistakes are often fatal.

Application

Perforated U-shaped profile (perforated profile) can be used in a variety of ways. So, such designs are very convenient when arranging cable routes. Wiring and alarms, cable TV and the Internet, wired telephony and special control communications: all this can be confidently connected in this way. In addition to these purposes, profile products are used by:

- for the arrangement of facades of private houses and public buildings;

- in preparation for decorating walls with tiles;

- during the construction of hangars, warehouses and other auxiliary structures;

- for installing gypsum plasterboard and gypsum fiber sheets;

- in the production and installation of racks for a wide range of purposes;

- in the production of plastic and aluminum windows;

- for the organization of ventilation, water supply, air conditioning lines;

- in greenhouses;

- in furniture;

- to strengthen the frameworks.

Materials (edit)

A simple steel mounting profile is actually not very common. More secure, more stable design options are generally used. So, the galvanized type is popular. Other options for metal profiles are used somewhat less often.

Basically, we are talking about products made of bronze and aluminum. Other metals are rarely used.

Pulling wires and other critical communications by default implies the use of particularly reliable metal grades. To protect the surface, resort to:

- hot zinc coating;

- coloring;

- simple cold galvanized;

- using stainless steel.

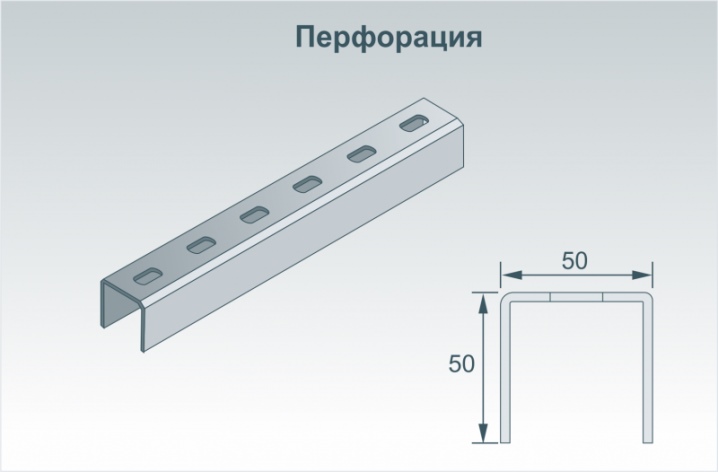

Dimensions (edit)

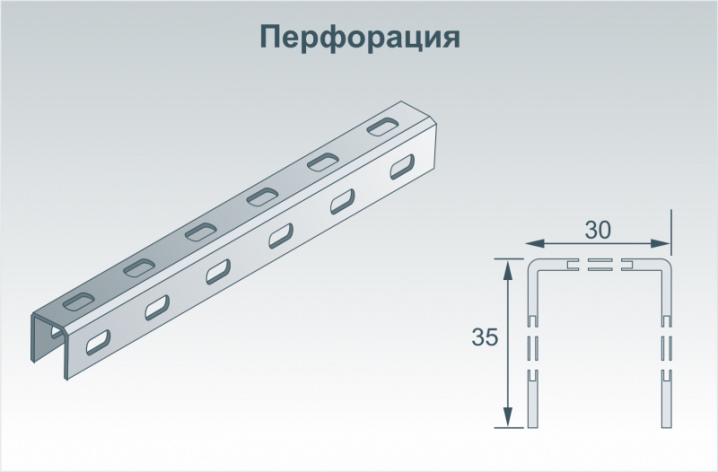

Structures with a size of 30x30x30x2 mm are widely used in installation work. Usually, this immediately provides for the presence of holes prepared at the production site. Drilling them is not required additionally. The typical mass of one element is 2.98 kg.

Important: in some cases it may differ, and this point should be discussed with the manufacturer.

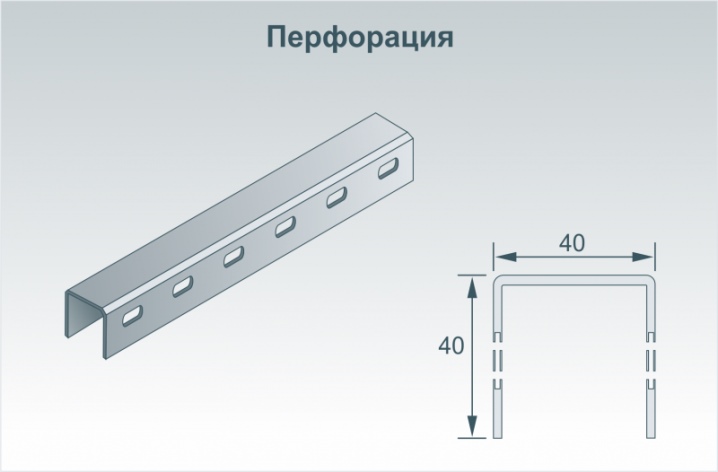

40x40 profiles are also not uncommon in the domestic market. By default, they are 2 mm thick. The mass of a single item is from 5 to 5.3 kg. Another regularly occurring option is 30x30. In this case, the weight of the product will be slightly more than 1 kg.

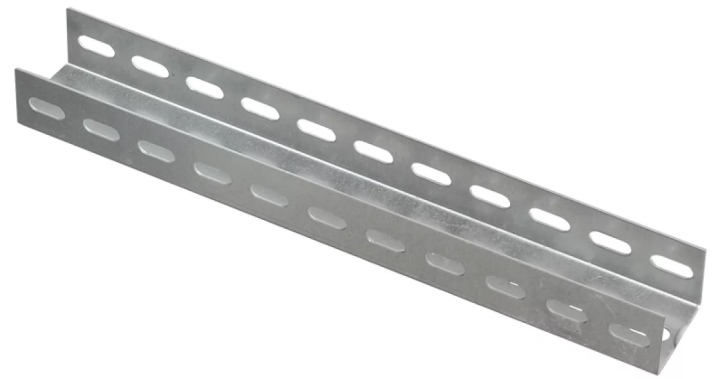

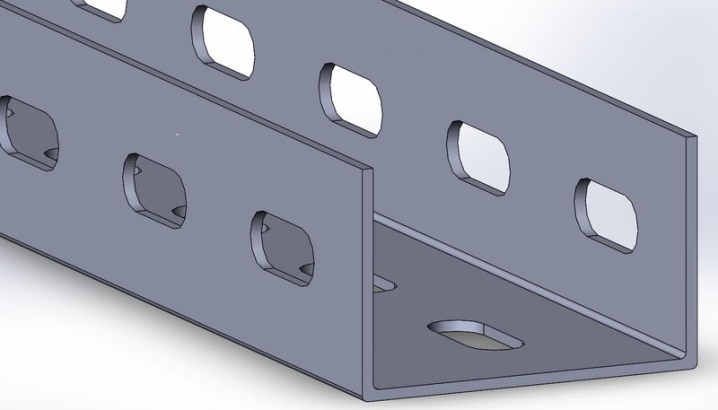

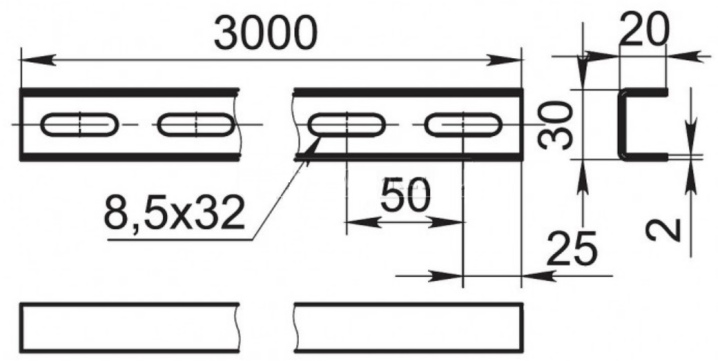

It would be logical to tell about the 40x30 mounting profile structures. Usually this is a perforated channel. On the scales, he pulls about 0.97 kg. Perforation in a number of variants is carried out only on the base. The Russian market can also offer customers a perforated tray with a size of 30x30x2000. Basically, it is obtained from high-quality ferrous metal, additionally protected from adverse factors by hot-dip galvanizing.

Ceiling profile structures 30x50x2000 also deserve attention. These products are used when installing cable trays. They also showed themselves well in the process of installing lighting devices. Continuous galvanized versions are preferred. Punching is usually carried out from three sides at once.

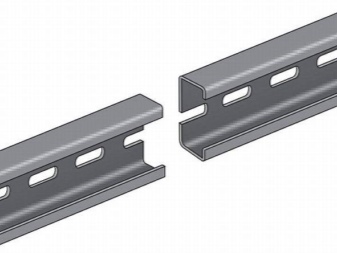

The size 50x50 is a very good solution for the formation of various racks. Such versions are used when arranging an interior partition. However, using them for the usual cladding of the main wall is also not a bad idea. The product is often cold rolled on modern lines. This approach is typical, for example, for Knauf factories.

Profile elements 60x40 are usually used when forming cable trays. Special perforations are usually made from three sides at once. Most often, the thickness of the metal is 2.5 mm. Many manufacturers prefer to use 08PS grade steel for such a product. But sometimes other grades of metal can also be taken, which should not be forgotten.

Some manufacturers promote 38x40 mm profiles... These P-shaped tires are great for both medium and heavy duty utility systems. Many of these structures are used to form wall consoles.

They are also bought to produce racks and frames of various profiles. Models are suitable for both dry and wet operating environments.

It is appropriate to complete the review on a perforated profile with a size of 32x20x3000x2. It is perforated mainly from the back. Electrolytic zinc coating provides special protection. The design is designed to fix the trays to vertical and horizontal surfaces in a variety of combinations. Advanced manufacturers prefer steel produced by the Sendzimir method (that is, thanks to continuous galvanizing).

The comment was sent successfully.