Everything you need to know about perforated profiles

Perforated mounting profiles are popular connecting elements of engineering structures. From the material of this article, you will learn what they are, what advantages and disadvantages they have, where they are used.

Advantages and disadvantages

Perforated mounting profiles are structures for fastening metal elements with perforations along their entire length. They have many advantages. For example:

- they can be repeatedly bent and unbent without fear of breakage;

- they are easy to adjust to the specific dimensions of the structures;

- they are practical, lightweight, designed for long-term storage;

- they are inert to external atmospheric influences (including rusting, moisture);

- they do not need welding and are attached to conventional anchor bolts;

- they are resistant to chemical compounds;

- products are characterized by low price and ease of installation.

Due to the increased resistance to moisture, the perforated profile is used in rooms with a high level of humidity. It does not break or deform in operation, it is considered a universal building material. Fireproof, harmless to humans and the environment, variable in hole sizes.

The perforated mounting profile is durable. Reinforced structures can be produced in various standard sizes. The building material is suitable for use in the construction of residential, commercial and industrial buildings. It helps to reduce labor costs.

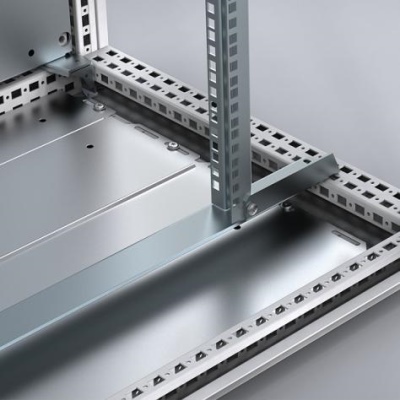

Thanks to him, it is possible to erect metal structures for firmly fixing cable lines, pipes, as well as various electrical devices to them. The use of a profile enhances the bearing capacity of the structures being erected. It reduces the load on the wall slabs as well as the base due to its low weight.

The perforated profile (traverse) assumes fastening directly to the wall (ceiling) or to racks (brackets). It can be not only a load-bearing, but also an auxiliary structural element. Perforation makes it easy to fasten bolts at any point in the profile. It can have different geometric shapes and sizes. It can be located on all sides of the profile or only on the base.

Its average service life is about 15 years. Due to this, premature repair of fasteners in the places of installation of engineering systems is excluded. However, depending on the type of material used, the service life may be shortened.

In addition, certain types of material are too thin. When working with them, you have to bend manually the paws, which are not very even. This complicates the work, such a profile is not suitable for installation. Structures with a minimum thickness can deform under weight load.

Despite the advertising, models with low-quality cladding are on sale. When manufacturers save on the zinc layer, the service life of the products decreases and the risk of profile corrosion increases. Therefore, you need to buy it exclusively from a trusted supplier, otherwise the declared advantages will not be saved.

The type of load on the products is also different. For example, only the perforated profile of the C-type can withstand the largest of them. Not all products on sale are created equal. Some of them are of poor quality, and therefore fragile. Good material is more expensive than simple options.

Species overview

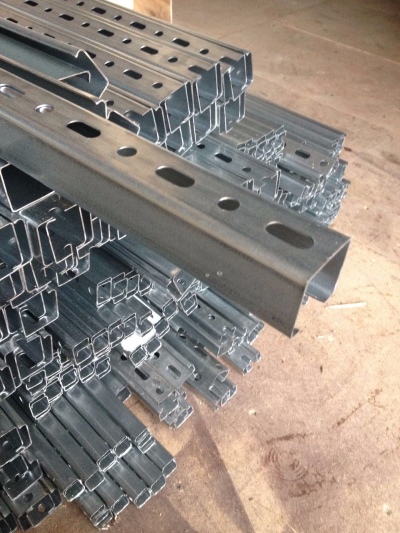

Perforated mounting profiles can be classified according to various criteria, for example: section type, size, type of material used in production, type of protective coating.

By type of material

Different raw materials are used in the production of perforated profiles. Depending on its type, the strength and performance characteristics of the modifications differ. For example, options from galvanized steel, bronze, aluminum are characterized by wear resistance, resistance to external negative factors.

The metal (steel, aluminum, iron) profile with holes is more in demand among the domestic buyer. Reinforced wiring material for metal structures is more durable. Depending on the type of application of the protective coating, hot-dip galvanizing, painting, galvanizing, stainless steel or another method of protection can be used.

By section type

The cross-section geometry of the perforated traverse may vary. It determines its strength characteristics and the type of use.

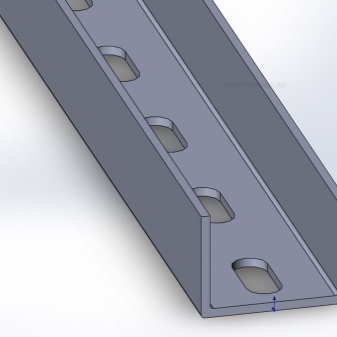

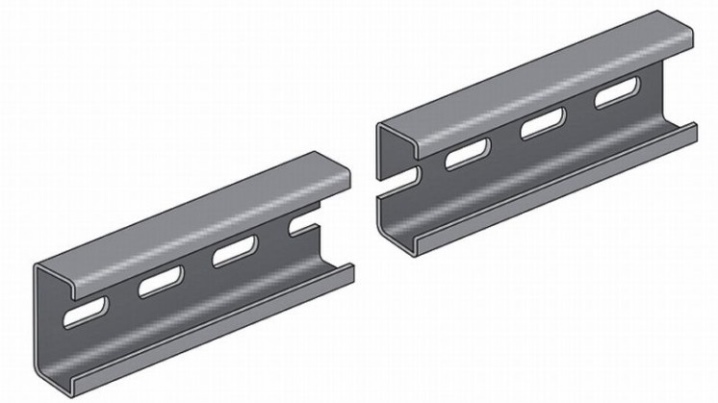

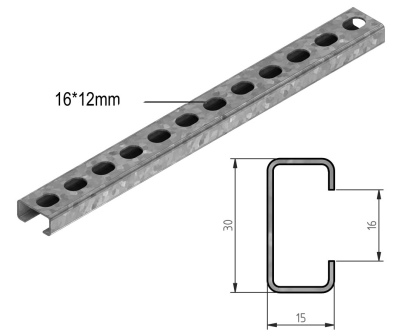

C-shaped

Such profiles are similar in section type to the letter "C". Thanks to the stiffening ribs, they have high strength with low weight, are resistant to abrasion, can have perforations on all or 2 sides, only the base. They can be used for plasterboard structures, which will allow the construction of any decorative and architectural objects.

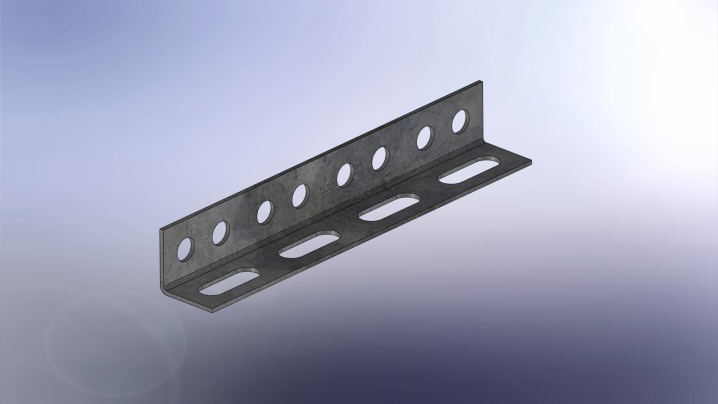

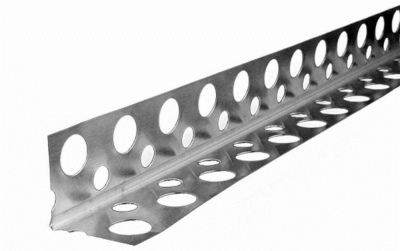

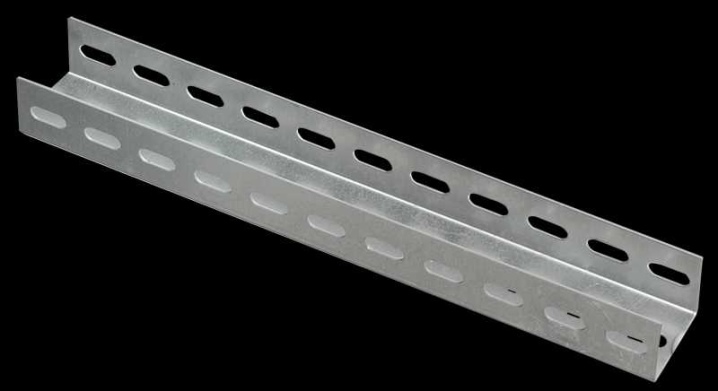

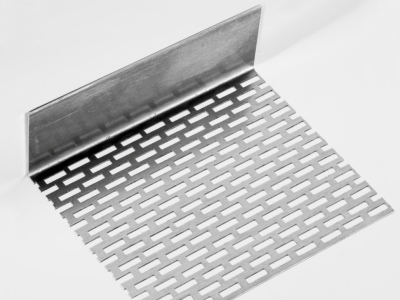

L-shaped

This profile belongs to the classic angular view. It is bought for the construction of shelving, frame, metal structures, laying cable, ventilation systems. This is the raw material with which the elements of different facade systems are fixed. The profile is steel and aluminum. It is produced on roll forming and bending machines.

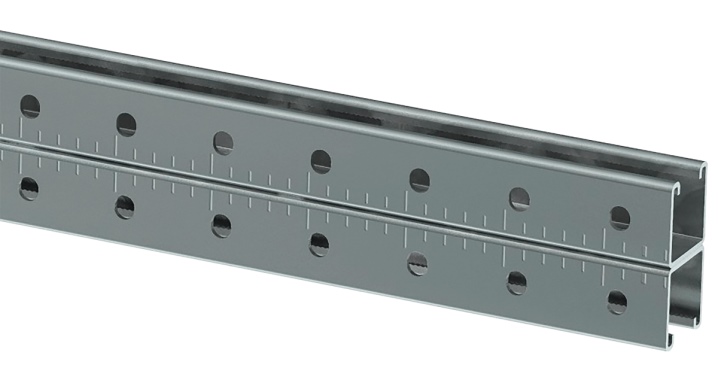

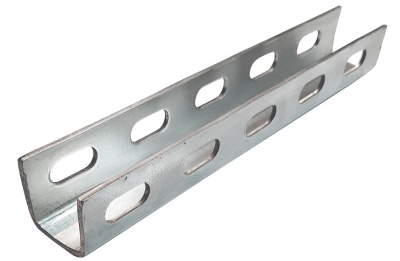

U-shaped

The channel is used as a guide or as an independent element in the construction of buildings. Thanks to him, it is possible to avoid colossal loads on building structures. They are placed vertically and horizontally, made of steel with a thickness of more than 2 mm.

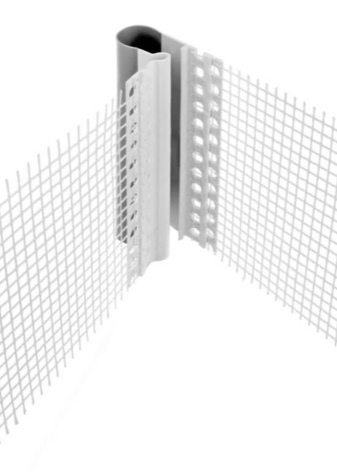

L-shaped

The L-shaped perforated profile is used to strengthen door and window openings. They strengthen the slopes, with its help they assemble pre-fabricated structures. It is used when installing drywall sheets.

In fact, these are the same L-shaped profiles, coated with a zinc layer or painted with powder paint.

Z-shaped

The Z profile is widely used in the assembly of steel structures. It is a necessary raw material for the construction of purlins in pitched roof structures. A perforated profile of this type is used in the arrangement of roofs with a further canopy on them of various structures. It has an oval perforation on 2 sides, which simplifies installation work.

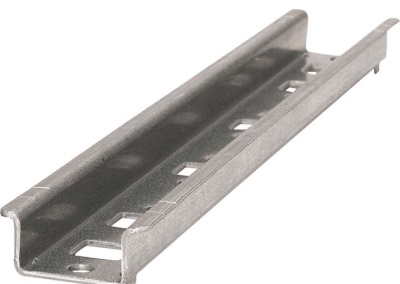

Omega profile

It is also called a hat. With its help, lathing is made for the facade and roofs. Thanks to the shape, the space under the roof receives additional ventilation.

Dimensions (edit)

The key characteristics of a perforated profile are the material of manufacture, as well as the parameters of length, width, height, thickness. The type of load that a particular type of product will withstand depends on them. A typical whip has a length of 2 to 6 m, while the running size is considered to be a mounting rail with a length of 2 m.

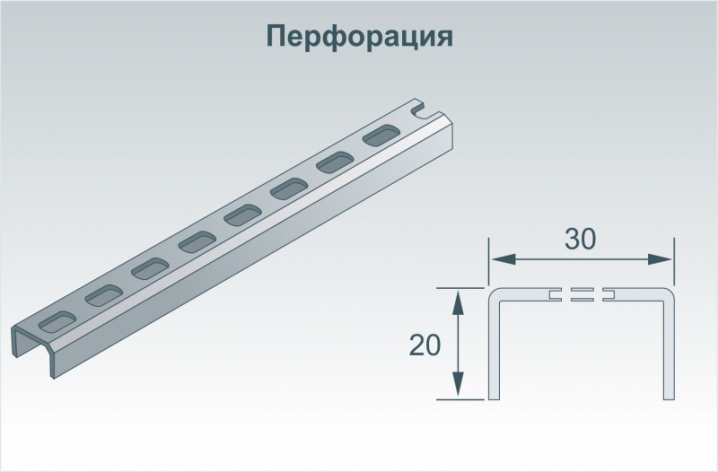

The thickness of the profile can vary from 0.1 to 0.4 cm. Depending on the shape of the products, the parameters can be 30x30x30x2000x2, 30x30x2, 6000x900, 80x42x500 mm. According to GOST, the section can be 40x40, 30x30 mm. At the same time, there are also non-standard options on sale with parameters 40x38, 40x20, 30x20, 27x18, 28x30, 41x41, 41x21 mm.

The width of the products can vary from 30 to 80 mm, the height - from 20 to 50 mm. In other modifications, the height reaches 15 cm.

In addition, enterprises are ready to manufacture products for individual orders. At the same time, production is carried out in accordance with the requirements of GOST.

Popular manufacturers

Various leading companies are involved in the production of perforated mounting profiles. Of these, it is worth noting several brands that are in demand from a domestic buyer.

- Sormat is a Finnish manufacturer with a leading position in the production of fasteners.

- LLC Stillline is a domestic supplier of angle-type or beacon-type perforated profiles made of galvanized steel and aluminum.

- LLC "Kabelrost" is a Russian trade mark that produces perforated profiles from sheet steel.

- "Crepemetiz" is a domestic manufacturer of perforated mounting profiles of various configurations (L-, U-, Z-shaped).

Besides, the products of the companies DKC, HILTI, IEK, Ostec (PP100) are worthy of attention. DKC supplies the market with products with a developed installation system that is used in many industries. HILTI manufactures profile systems with a special design, thanks to which it is possible to speed up the reliable installation of façade systems.

IEK manufactures electrical equipment used for equipping construction, energy, industrial, transport and other facilities. OSTEC supplies profiles for the arrangement of cable networks. Among other companies, we can also mention the products of the ASD-Electric trademark.

Applications

The perforated profile has found application in various fields. The main one is construction. For example, you can't do without it:

- laying of cable routes, ventilation and air conditioning, lighting systems (outdoors and indoors);

- construction of building facades;

- preparation of the base for the tiles;

- construction of warehouses and hangars.

The perforated profile is used for the installation of drywall, the manufacture of shelving structures for various purposes, it is bought for the installation of PVC windows. A galvanized profile with perforation is used for laying engineering communications (ventilation, water supply, power supply, air conditioning).

It is taken for cladding, structures are strengthened with it. It has found application in the manufacture of furniture, it is used for household needs (for example, for the installation of greenhouse structures or shelves). In this case, the holes can be not only single, but also double.

The perforated channel can be used as a lot when laying cables and installing a lighting device. Such material is used in household and industrial areas. In addition to construction, it is used in design, mechanical engineering, and the mining industry.

With its help, decorative decorative panels and ventilation ducts are created. It is used for wall decoration of premises, basements. Variants with a non-standard section are used for mosquito nets, stretch ceilings, advertising.

Some types are used in the arrangement of greenhouses, garages. Modification parameters are selected depending on the purpose of the profile. At the same time, the sizes of structures can vary from minimal to bulky. The load can be light, medium, high. Models can be equal and unequal.

The comment was sent successfully.