Overview of furniture profiles and their selection

Familiarity with the overview of furniture U-profiles for protecting furniture edges and other forms is very important. When choosing them, attention should be paid to decorative PVC profiles for facades and metal chrome-plated, other types of fittings.

general description

Furniture profiles are a whole category of products that connect furniture pieces into a monolithic system or give an assembly an attractive appearance.... Sometimes these products are also called furniture fittings. There are a large number of firms that produce it - both domestic and foreign companies. The profile can be obtained using methods such as stamping or rolling. The functions of furniture fittings are varied.

A wide range of materials are used for its manufacture. Therefore, a very high decorative effect can be easily achieved. Both the color and the geometric shape of the finished elements vary. And also we must not forget about the constructive task. A real high-quality profile acts as a supporting and connecting element, it turns out to be the frame of the facade being created.

The protective role of the profile is that it reduces the risk of mechanical failure. Geometrically, such a product must be matched to the furniture being created as carefully as possible. After the fittings are installed, the structure as a whole lasts longer.

Edges and ends are largely insulated from contact with water. Profile models are both strong and lightweight, which allows you not to fear unnecessary stress.

Views

The facade profile can be used primarily for glass kitchen facades. But this frame product is used in other cases as well. It is allowed to be used for framing wooden and plastic structures. Such a furniture profile is also used as a base for a wardrobe. You can see it not only in kitchens, but also in:

-

children's;

-

living rooms;

-

bedrooms.

The overhead cornice is also worth mentioning. This is an attractive type of decorative products, which is very diverse in appearance and in the level of relief.... Such profiles are mainly used to decorate the upper sections of cabinets. This hardware has a rather complex structure (it is divided into several blocks). There are both monolithic and glued cornices. They are mainly used to decorate finished interior items.

Side skirts can play an important role in practice. They are the ones that help protect the tops of the kitchen countertops. A typical side plate has a flush mount type.

Besides covering from moisture, dust and dirt, such designs allow you to improve the appearance of the structure and complement it.

Decorative and protective properties are also combined in various planks. But their main purpose is still to keep individual parts in a bundle, the strength and stability of the furniture product. To protect the edges, a product is used, which is called a furniture edge. It is mainly mounted on the end face of particle boards. There are different designs - ABS, melamine-based, PVC, acrylic 3D.

There is also an angular type of profile. In many cases, it is made from aluminum. Some modifications are simply mounted on the surface, while others are also suitable for organizing lighting.A flexible profile for finishing curved and rounded sections is found on sale in a large assortment. Separately, it is worth mentioning the edge profile for boards and shelves, as well as a decorative self-adhesive type, supplemented with a special adhesive tape.

Materials (edit)

For the manufacture of a profile, various materials are used, which allows you to vary its flexibility and rigidity. Easily bendable structures are needed for finishing curved areas of complex shapes. Simple straight elements are finished with rigid structures. They are created from metallic substances, including aluminum alloys. The use of aluminum is attractive because of its:

-

lightness;

-

relatively high strength;

-

long period of service.

The advantage of non-ferrous metal is resistance to corrosion and mechanical stress. Products made of ferrous metals can also be used. Among them, chrome-plated steel alloy is considered the best option. The fittings can also be made from the MDF profile. It is an environmentally friendly, long-lasting material in a variety of shades. Meet:

-

typesetting and support profiles;

-

cornices;

-

frame models;

-

overlays.

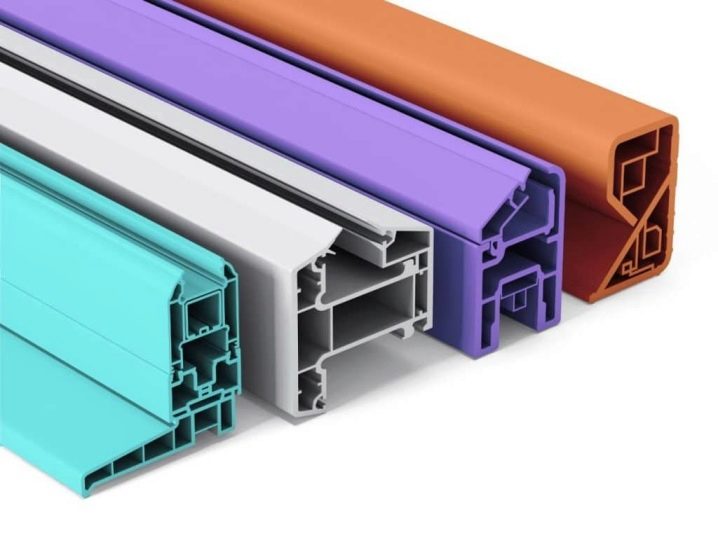

Plastic profiles are also in demand... They are created mainly on the basis of PVC for the design of the end sections of particle boards and MDF panels. Flexible polymer structures are mounted overhead or cut-in method. In a number of models there is a girth, although sometimes it is possible to do without it. Such designs can give the finished product any color and reliably prevent moisture seepage from the outside.

Profiles from solid wood are occasionally used. They are predominantly suitable for frame structures. Hard wood is not economical enough.

Its use can only be justified for decorative reasons. The final decision, however, is always made by the customers themselves.

Shapes and sizes

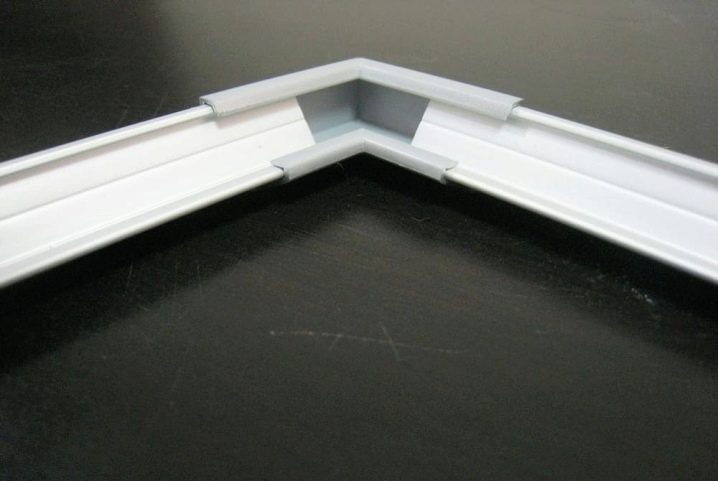

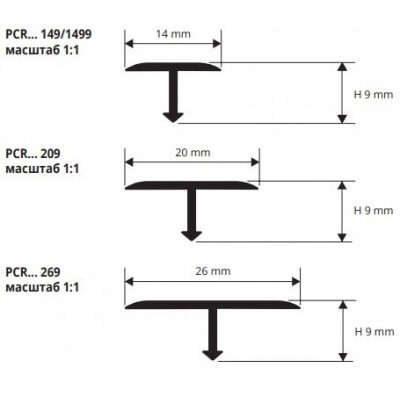

Geometry is largely based on the materials of manufacture. The U-shaped profile made of polyvinyl chloride is divided into rigid and flexible varieties. Rigid type is preferable for straight façade. In some cases, the T-shaped structure helps to improve the fastening. The width of such fittings is in different situations:

-

16;

-

18;

-

32 mm.

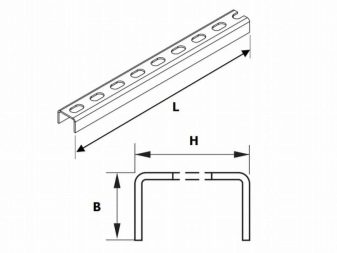

Aluminum profiles are also widely used (for example, T22 fittings). Such products have 3 functional grooves. The usual length is 3 m. Frame structures are mainly made in the form of a square or rectangle. Some versions have a rounded face. The mounting slots range from 4 to 10 mm.

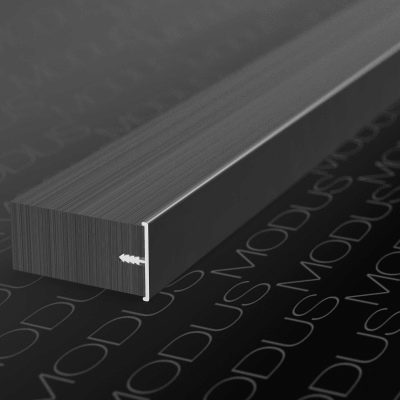

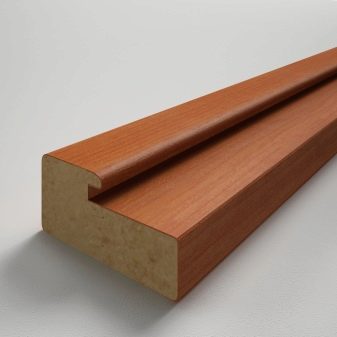

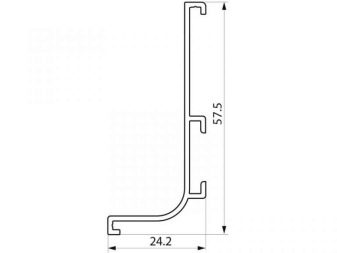

The cut-in surface-mounted fittings of the aluminum handle can be made in the form of the letters L, F. There are also C-shaped, T-shaped and U-shaped versions. The industry has mastered the production of such products with sizes from 60 to 2000 mm. Profile linings on MDF can usually be L-shaped, U-shaped or C-shaped. The length of such products reaches 2,795 mm, their thickness is from 16 to 22 mm, and their width ranges from 50 to 60 mm. With additional cladding, the width can be increased up to 80 mm.

Nuances of choice

Even a brief description of the main features and areas of application shows that for furniture, such products are quite valuable and relevant. The more important it is to select them correctly. Aluminum is used to make rigid structures. Even lightness does not interfere with providing high strength. And also non-ferrous metal products should be chosen for:

-

finishing furniture used in particularly humid places;

-

the embodiment of high-tech, loft and related styles;

-

creating the most robust and durable structures.

MDF is preferable for finishing ends... It is also used for furniture with non-standard sizes and sections. This material works well in dry places where there is no danger of wetting the furniture body. Fittings based on MDF are regularly used for individual orders. Another important advantage will be the high speed of installation.

PVC is prized for its economy... These edges do not need to be adjusted in width. However, the disadvantage is the lack of durability of the structure. Sizes and colors should be chosen at your own discretion.

It must always be ensured that the profile is suitable for the highest possible loads. We must not forget also about the performance of the products and about the reviews about their qualities.

The comment was sent successfully.