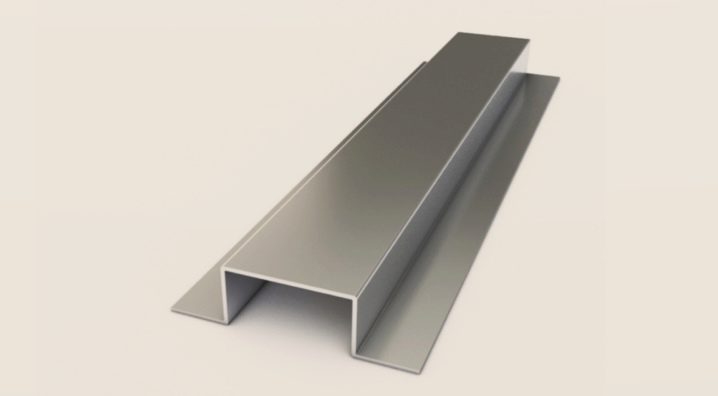

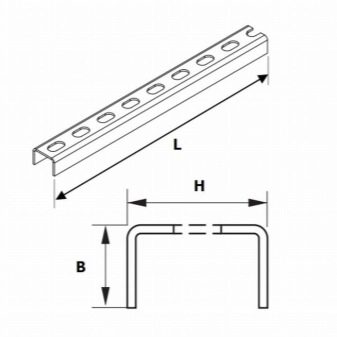

Metal U-shaped profiles

The metal profile as a type and class of an element for load-bearing structures has penetrated into all spheres and branches of construction and mechanical engineering. Steel and aluminum U-shaped strips are used in construction, repair, decoration of buildings and structures for residential or industrial purposes.

Peculiarities

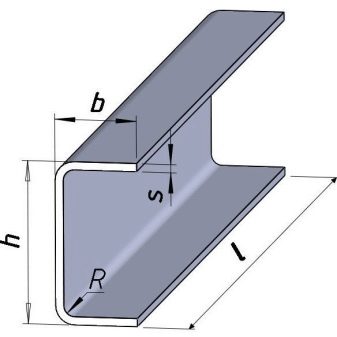

The metal U-shaped profile resembles similar guides having a G-, Z-, S-, C-, U- or X-shaped cut. Theoretically, you can create a profile with a cross-section that resembles any letter or number, but the most common is the P-profile. The latter is similar to an I-beam, in which the longitudinal plates are arranged in pairs and opposite at acute angles to each other, and not mutually perpendicular. And the similarities here are as follows: the grade and properties of steel (alloying additives that determine the strength and anti-corrosion characteristics), wall thickness, section length, coating - they are practically the same. GOST imposes an error up or down in length - it does not exceed 2 mm for a 6-meter section, and the thickness can differ by only 1% from the nominal.

Compared to reinforcement and a one-sided strip, it is more difficult to bend the profile. Bend it while heating the bend over the nozzle (nozzle) of the gas burner. To bend the profile, as well as the round, square professional pipes, using a concentrated (high-speed) flame, they heat the steel to a temperature of the order of 1300 degrees, at which it begins to soften. But this method is used only when the evenness of the sides of the profile is not important. Otherwise, it is possible to bend the profile only by sawing the section at an angle of 45 degrees, while the cuts should be counter-identical. Then, having removed the extra corner piece (90 degrees in the corner, if the profile rotates at the same angle), it is welded at the cut.

Unlike a round pipe and a square professional pipe, the U-shaped profile cannot be bent with the formation of segment-angular folds: the sidewalls would be crumpled in this case.

This is the difference between open profiles and pipes and solid rods.

Views

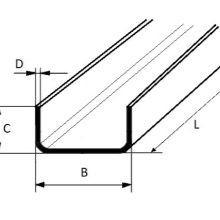

The release of the P-profile is set strictly by the standards of GOST No. 8240-1989 and No. 8278-1983. Dimensions of the P-strip - the width of the side and main walls, the length of the longitudinal section, the wall thickness (as a rule, it is constant).

By manufacturing method

The rolled profile (by the hot-rolled method) is produced with sides from 50 to 400 mm in width. Section length - 2 ... 12 mm. Large U-profile (cross-section) is a typical channel: the wall thickness is sufficient to be used as lintels for window and door openings.

The bent profile is made using special machines that accurately fold it. Material - rolled steel produced at low and high temperatures. At the same time, steel of average quality is used, as well as a low-carbon grade with a small amount of alloying additives. Low-carbon steel bends more easily, it is wound on drums - in a roll. The thickness of such steel is 0.2 ... 20 mm. Galvanized steel has proven itself well - it is not hot-rolled, this made it possible to switch to the production of limited batches of billets. Profile walls with a thickness of up to 0.8 mm allow the use of the manual bending method. Automated sheet bending machines will cope with a noticeably greater thickness. The bent profile does not withstand the increased load, in contrast to the initially rolled one on the conveyor.The advantage of the bent profile is uniformity and uniformity along the entire length, facilitating the welding process at the joints.

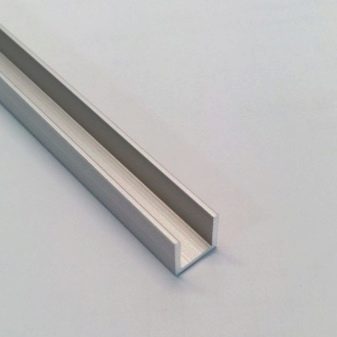

Pressing of a U-profile is carried out on the basis of aluminum blanks, since it is difficult to press alloy steel in this way. They are produced by stamping. Aluminum is a light metal, it is three times lighter than copper, but its disadvantage is its low vibration damping ability, which significantly affects its strength characteristics: it bursts with excessive vibration. It is suitable only for the construction of lightweight partitions. But high humidity aluminum alloys withstand well - which cannot be said about vapors saturated with salts, alkalis and acids. For greater protection, the profile is painted with paints and varnishes, coated with metals by anodizing (in small quantities), protective compounds based on plastic are applied to them, and a complex double coating is used.

An additional layer improves the appearance of the structure - this method is relevant for assemblies that are not hidden under the panels.

To size

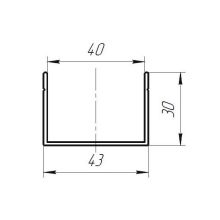

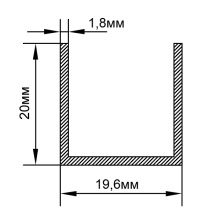

Thicknesses of 2, 3, 4, 5, 6 and 8 mm are most often found in the range of profile products. Examples of typical profiles - 30x30x2 (wall thickness - 2 mm, sides - 30 each), 40x40, 50x50, 80x40 (main edge - 40, sidewalls - 80 mm), 20x20 (sides and main side are equal), 100x50 (50 - main side , but it happens the other way around), 10x10 (sides), 40 mm (similar), 30x50x40 (profile with unequal sides, resembles an L-shaped one with a wide bend). Examples of marking with special parameters:

-

"5П" - parallelism of edges;

-

"5U" - sloped edges;

-

"5E" - economical thin-walled profile with parallel sidewalls;

-

"5L" - lightweight with parallel sidewalls;

-

"5C" - special purpose: the edges can be located not perpendicular, but oblique.

In the latter case, such a profile has an unusual cut, somewhat different from the letter "p" in the cut. The second case is a butted profile element with variable wall thickness and sidewall spacing and differing in its length in the width of the main edge. Such products are rare, and they are produced only by special order.

Large blanks with a width of the main face and / or sidewalls of the order of 10 cm have a corresponding wall thickness of 1 cm or more. Their purpose is steel beams, pillars, all kinds of supports. As an example, a reinforced foundation, in which channels are used, for example, for a heavy plate steel bath stove. These beams are produced from plain black steel by rolling method.

When a project comes across any special research, the production of a certain group of blanks is decided individually.

The middle grade - profiles with walls about 3 ... 10 cm wide. They are used for arranging utility rooms, frames of gazebos, as a support for a fence made of profiled sheet, etc. erection of buildings for specific private household plots, all kinds of one-story construction. When you need a channel, you should not use a profile with a marker "L", "C" or "B" - these blanks are used in mechanical engineering, for example, in machine tool production.

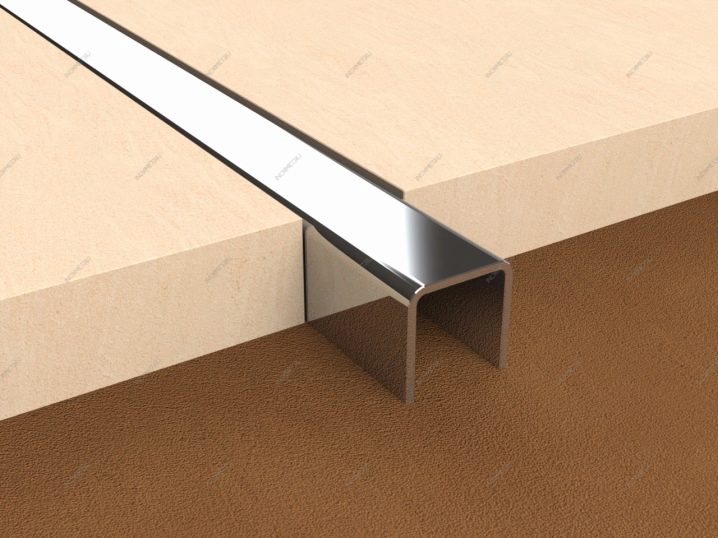

Small-profile components - less than 30 mm per edge in width - are mainly used in decoration. The use of such a profile in practice is difficult: it will not withstand the bearing load of walls and floors. However, it is used as shelf and rack components in all kinds of warehouses. A small profile, for example, in combination with the same size (cross-section) pipe can be used for the production of sofas, beds and armchairs.

Its auxiliary use as a tool is clamps, mini-vices for welding on steel, for example, in the production of all the same steel furniture.

Materials (edit)

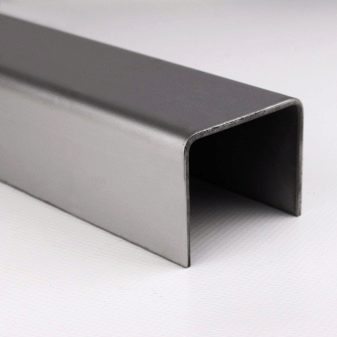

In addition to the steel - including galvanized - profile, stainless steel blanks are common. Due to its high viscosity, stainless steel is difficult to process, but in return you will receive a design that will last for your lifetime - and such an assembly will serve several more of your subsequent generations.

A black galvanized iron U-profile is one of the cheapest options. Without galvanizing, it - in conditions of heat and humidity - will last only for several years. Then such a structure simply crumbles.

The steel profile is marked as cold-rolled steel - "08 ps", "08 kp", "08-U".

Hot-rolled steel - "St 3ps", "St 3 sp", "09G2S", "S235", "S245", "S255", "S275", "S345", "10 HSND" and several similar options. Aluminum profiles are usually not marked - the use of brass, bronze and magnesium alloys is not common. But galvanizing according to the standards of GOST No. 14918-94, GOST-R No. 52246-2004 with "350" rolled products has a first-class (according to the nomenclature of profiles) zinc layer (275 gr.). Stainless steel is marked as "12X18H9T", "12X18H9B", "12X18H10T", "12X18H10B". Choosing a workpiece (or a batch of segments) suitable for specific purposes, they are guided by the tasks set before the master and the conditions for using the components. It is also possible to produce these blanks using handicraft methods, guided by GOST, however, few "home-made" people can afford this: this requires an analogue of a blast furnace. Steel can be galvanized or copper-plated using zinc and copper salts - you only need to immerse the steel billet in an electrolysis solution (or melt).

Applications

The steel profile, due to its high strength, is mainly used for low and high-rise buildings. Nevertheless, attempts to replace a larger channel with a few small ones are fraught with overruns of the target budget, and the strength of such a structure will be questionable.

The all-metal profile is a frequently used finishing component in practice. Aluminum and copper-plated profile sections are "companions" of expensive furniture: glazed shelves, shelves, pedestals, etc. They are used as design elements in study rooms and offices: they are used to trim glazed partitions. In hospitals, the aluminum profile is used as a supporting structure for screens, in educational institutions, including special schools, as a frame for a blackboard. In classrooms where projectors are installed, the whiteboard is also decorated with copper-plated, pure aluminum or painted profiles. The U-shaped structure easily "fits" onto the edge of the board, screen, panel.

A thin-walled steel profile (up to 1 mm) is used for the construction of temporary floors and partitions. Large rooms can easily be divided into separate zones.

For example, cases when a certain area of the corridor, facing the outer wall of a building with a window, was fenced off and turned into a new office is not uncommon.

A square professional pipe and a U-shaped thin-walled profile are often used as an internal space for laying cables and pipelines. P-profile is a very common element for additional roofing, fasteners, garage equipment, metal-plastic windows, and closing openings. This list threatens to become endless. In windows, as an external plastic U-profile (polypropylene), reinforced blanks are used, into which perforated (with holes) strips, internal (steel) U-blanks and / or corners are screwed, as a result, the structure of a metal-plastic window acquires increased rigidity. Powdered insulation is poured into the technological passages of the resulting structure (or a highly porous filler is filled), and then rubber seals are laid and a double or triple glass unit is installed. Legrand closing boxes, created for cable "engineering", by the way, are also a U-profile with a longitudinal flexible cover and sidewalls-plugs installed from the ends.

The comment was sent successfully.