Features of metal profiles

Metal profiles are widely used in various assembly jobs. Such designs have many advantages over wood or plastic parts. In addition, there are different types of metal profiles, which allows them to be used in a variety of conditions. In this article, we will understand all the features of metal profiles.

Advantages and disadvantages

Currently, metal profiles are used in a huge variety of jobs. Such parts are suitable not only for installation, but also for decorating various bases. This indicates the multifunctionality of the structures under consideration.

Profiles made of practical and reliable metal are in great demand, since they have a lot of advantages. Let's find out about the most significant ones.

- The main advantage of metal profiles is the level of their reliability.... Such products are made of high strength and sturdy, they are difficult to damage. High-quality metal does not undergo deformation in a wide variety of operating conditions.

- Despite its strength characteristics, modern metal profiles are lightweight. Such elements make it possible to build high-quality lightweight structures. Thanks to the moderate weight, working with the profile parts is simple and convenient.

- The products in question are easy to install. If you use high-quality profiles, then the assembly of reliable metal structures will not require much time and effort.

- Price the materials in question can be quite democratic.

- Metal profiles are multifunctional products. A huge variety of structures and structures can be made from them. Similar details are also used during finishing work, for example, for leveling wall bases.

- High-quality metal profiles boast a very long service life. Reliable and durable elements are distinguished by their durability, which, coupled with wear resistance, makes them indispensable components for many installation work.

- The metal profile has very good seismic resistance. Thanks to this, structures assembled from it can be mounted even in earthquake-prone areas.

- Modern profile models are made of high-density materialstherefore they are impermeable to gases or liquids. In addition, high-quality perforated products are characterized by thermal conductivity comparable to those of natural wood.

- Currently, high-quality metal profiles are sold in many hardware stores and shopping centers. In order to find a reliable and necessary part, the buyer does not have to look for it for a long time while driving around the city.

Metal profiles are environmentally friendly and safe products. They do not contain hazardous components and harmful substances that can negatively affect human health.

Due to the listed advantages, metal profiles and iron pipes of different diameters / sections have gained immense popularity. However, these products are not without some disadvantages.

- The main disadvantage that the metal profile and various iron products have is their susceptibility to corrosion. In order not to face such problems, the products have to be additionally treated with special anti-corrosion mixtures and solutions, which entails additional expenses. Galvanized models that do not corrode are more expensive.

- The heat resistance of the products under consideration is not high enough. Excessive temperatures can cause metal profiles to change their original shape.

Views

Today, various types of metal profiles are used in construction and installation work: curved, angled, flexible, and so on. They differ from each other in their direct structure and dimensional parameters. The manufacturing method of these products is also different, as well as the scope of further application.

By production method

The existing varieties of metal profiles are divided according to the method of their direct production, which meets the standards of GOST. There are different types of products on sale:

- hot-deformed;

- cold-deformed;

- electrowelded;

- cold-worked electrowelded.

The first two types of metal profiles are characterized by noiselessness. These types of structures are very popular because they have good performance and quality. Let's learn the main features of hot-worked and cold-worked profiles.

- These varieties are almost not subject to any deformation.even if they are subject to a noticeable mechanical load.

- These shaped products are relatively inexpensive, especially when compared to standard pipes. The affordable price is due to the fact that this building material is made from less metal, since it has a hollow structure inside.

- Weight the types of metal profiles under consideration is small.

- Metal products are characterized by excellent resistance to various corrosion... The only exceptions are galvanized specimens, which are used in rare cases.

Electric-welded steel structures are manufactured using various technological methods. In this case, different machines can be used. Several different treatments of the base material are carried out. Electric-welded shaped pipes are made by pressing round billets, as well as by connecting strip shaped elements.

Today's cold-formed electrowelded shaped products are made from billets that are rolled to the desired shape, such as pipes. Materials that are produced using this technology can often be found in the design of various systems that have special safety requirements.

Cold-formed electrically welded products can be very heavily loaded.

By shape and size

Metal profile parts also differ in structure and dimensional values. First, let's find out what forms metal profiles of modern production can have.

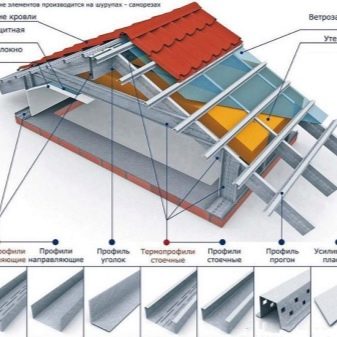

- Z-shaped. Such types of structures are widely used in the arrangement of strong and reliable interfloor ceilings, differing in impressive length. In addition, the metal materials in question are suitable for the construction of pitched roofs.

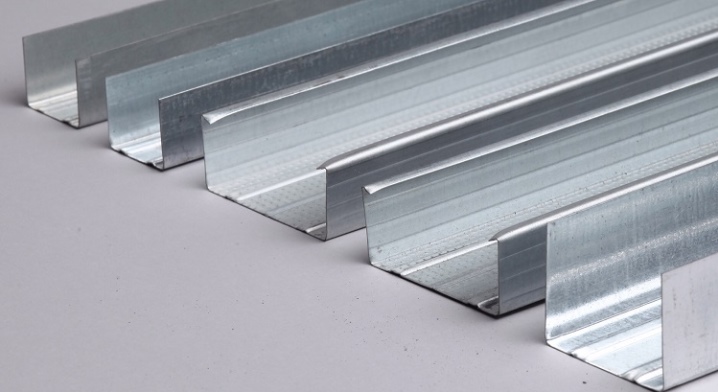

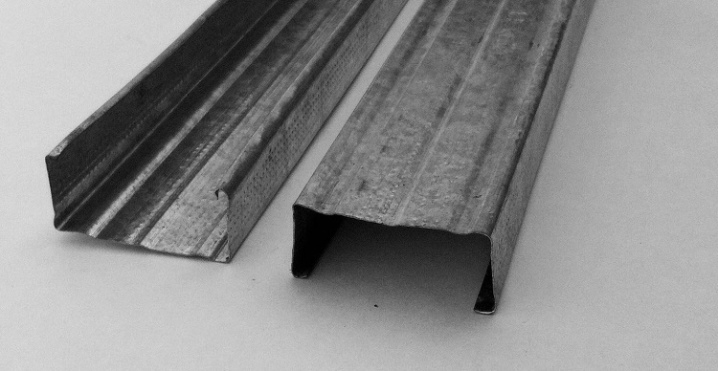

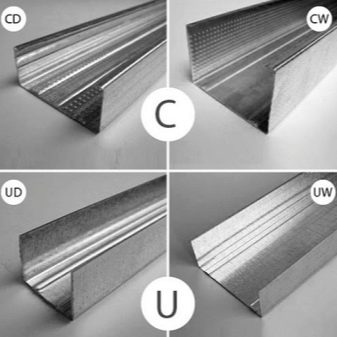

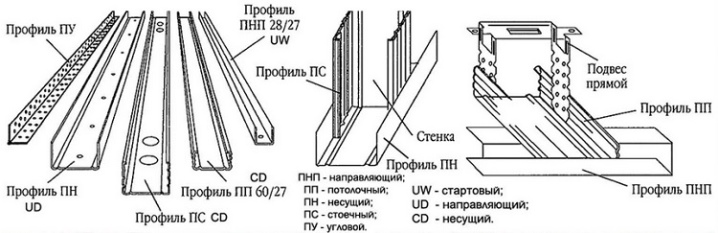

- C-shaped... Metal profile parts, the shape of which repeats the letter "C", are most often used for the design of battens or additional and auxiliary structures for installing panels (both insulating and cladding). C-shaped models can also be used when working with wall bases. The varieties under consideration are distinguished by the increased strength of the materials.

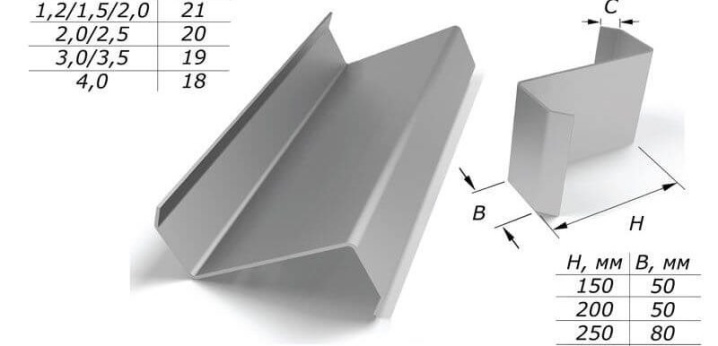

- U-shaped (rack-mount). No less popular types of metal profiles. These types of products have found their application in the arrangement of guiding profile structures used in frame construction.The length of the specimens under consideration usually reaches a mark of no more than 15 m.

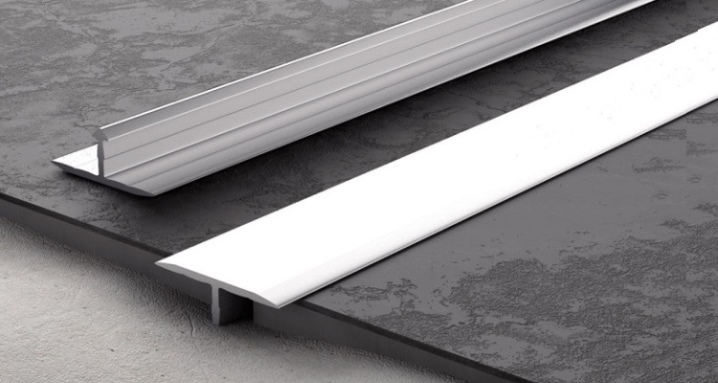

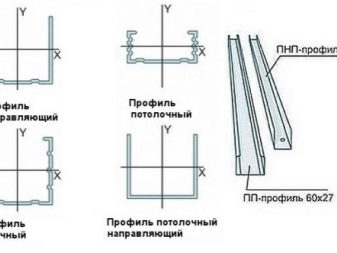

- T-shaped... High-quality models of ceiling profile parts have a similar structure. Usually, such products are used to design the lathing, which plays the role of fastening various finishing materials. As a rule, T-shaped profiles have a cross section of 60x27 mm.

Different categories of profile specimens may have different dimensional parameters.

- Guide parts marked with UD mark, are characterized by dimensions of 0.25-0.28x300-400 cm. The wall thickness of these types is usually 0.5-0.7 mm.

- Bearing types of profiles with UD marking have the following dimensions: 0.25-0.28x300 cm. There are also options 0.28x400 cm. In absolutely all variations, the shelf height reaches 0.5-0.6 mm.

- If we talk about metal profiles for the construction of partitions, then they are usually wider... For example, models marked UW can have a width parameter of 50,75,100 mm. The length of these products is 3000 or 4000 mm. The weight of each of the copies is 2.19-3.88 kg.

On sale you can also find metal profile products with dimensions of 60x60, 30x30, 40x40, 100x100 cm and so on. There are flat types of profiles. Different manufacturers make products in different lengths, widths and thicknesses.

By scope

Absolutely all modern models of metal profiles are divided into different types based on the scope of their direct application. We will find out exactly where different variations of these high-strength products can be used.

- Modern square types of profiles are very popular.... They are used as a base for fastening ceiling and rack structures.

- To make the crate, the T-shaped products discussed above are involved.

- Rack varieties are used for assembling frame bases of load-bearing camps and other structures. These types of profile components are attached to rails installed on the ceiling, walls or on the floor.

- Corner types of products zThey are used for fixing corners when filling plasterboard substrates.

- Beacon species profile parts are used to form a more leveled and neat surface of walls made of brick or concrete.

The current assortment of metal profiles allows you to choose the optimal specimens suitable for the construction of roofs, plinths, partitions, awnings, and reinforcement of openings.

Color solutions

Currently, in specialized stores, buyers can find a large number of high quality metal profile parts. Such products differ not only in their dimensions and structure, but also in color.

Not only standard, but also more original decorative products are widespread, the surface of which imitates other expensive materials, and not only single colors.... For example, it can be interesting specimens with surfaces like stone or wood. Gold and bronze profiles look bright.

The minimalistic white and black options that are very popular today are universal.

Components

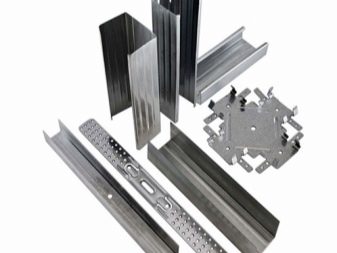

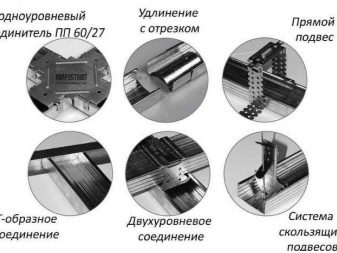

The construction of frame bases from metal profiles is impossible without the use of special components. These elements include:

- internal connecting parts of the corner structure;

- longitudinal connectors;

- crossbar connectors;

- plugs and bugs;

- two-level and one-level connecting parts (popularly called "crabs");

- direct types of suspensions (these parts are used exclusively when installing a suspended ceiling).

Instead of angled connector options, you can also use siblings, which are cheaper. But one should not forget about the risk of deformation of the frame structure in the case of using a "crab".

To securely fix the metal profile, for example, for drywall sheets, use ordinary self-tapping screws or screws with anchors. Due to the use of these components, a stable fixation of the joints is ensured to the maximum.

Marking

Different types of metal profiles are marked differently. Consider what the existing markings mean.

- CW (international brand). In a similar way, metal profiles intended for the installation of drywall sheets in the design of partitions and other surfaces are marked.

- CD... Western European marking, which designates modern metal profiles. The specified combination of letter values often denotes ceiling, T-shaped products.

The comment was sent successfully.