Everything you need to know about profile crabs

This article describes everything you need to know about "crabs" for profiles 60x27 and other sizes. The connection “crab” for drywall and the connector-system for profile pipes are characterized. It is clearly indicated how exactly they should be fastened.

What it is?

A robust and stable drywall frame cannot be created without the use of specialized connecting parts. These so-called "crabs" for the profile got their name from their visual resemblance to the famous inhabitant of the seas and oceans. But the coincidence is, of course, coincidental.

To obtain such parts, it is customary to use special grades of galvanized steel. Experts agree that without such connecting blocks, it is not necessary to count on the strength and rigidity of the metal base under the gypsum board.

They guarantee the docking of guides and battens located at right angles to each other in a single plane. Yes, it becomes possible to mount sheets in arbitrary planes. This circumstance will help make repairs easier and faster. Even if the installation of sheets is planned on the ceiling of a house or other room. But the described system for profile structures can be used not only as part of the plasterboard sheathing.

It is also used:

-

to form barriers (partition structures) inside buildings;

-

as a connector for suspended ceilings with complex shapes;

-

to mount dissimilar metal structures (in this case, the connection point should be in the middle of the "crustacean").

Additionally, the "crab" may be required when forming:

-

various greenhouses;

-

gazebos;

-

trade tents;

-

winter gardens;

-

advertising structures;

-

bird cages;

-

office and home partitions;

-

frames of small pools;

-

architectural forms of various kinds.

Main characteristics

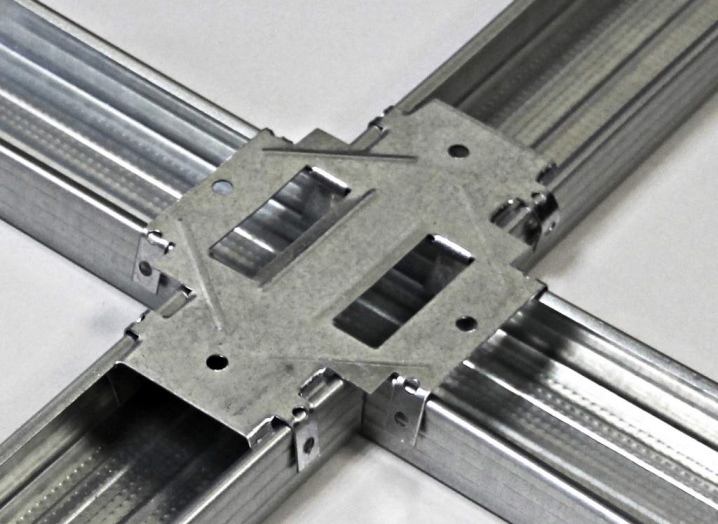

The connecting crab is a cruciform block obtained by stamping metal. The total thickness of the product ranges from 0.6 to 0.8 mm. Crabs have curly "legs" bent to the side. Such petals just become specific "antennae" capable of snapping into profiles.

A zinc layer is applied to black steel.

But the designers did not stop there and also provided for an auxiliary pair of "legs", all sides of which were equipped with holes. This is no coincidence - such a technological solution increases the strength of the joints. It is guaranteed in any case, even if the impact on the frame is 20-25 kg per 1 m2. The centrally located axles are equipped with mounting holes. Through these holes, the crab can be placed directly on the surface to be served or by means of an adjustable suspension.

An important advantage of such elements is that they do not need to be installed using gas or electric welding. This will hardly affect the strength of the joints created. The main properties of the profile "crabs":

-

suitability for repeated use;

-

dismantling with one adjustable wrench, in the absence of other tools;

-

the breadth of the scope of operation;

-

uniform dispersion of the force applied to the frame;

-

compatibility is strictly with small-sized tubular profiles (it will not work to put the connector on large pipes);

-

suitability for joining pipes only at right angles;

-

danger of destruction of the connection;

-

problems with the geometric characteristics of the frames;

-

the likelihood of corrosive changes (without special treatment).

Quite often the "crab" is used for steel parts 60x27 in size. A typical connector of this format has a size of 148x148. It is mainly used for mounting drywall to the ceiling. And it is in this quality that the products of the 60x27 categories are present in a variety of catalogs. But for greenhouses and other tubular structures, "crabs" are preferable:

-

20x20;

-

40x20;

-

50x50.

Species overview

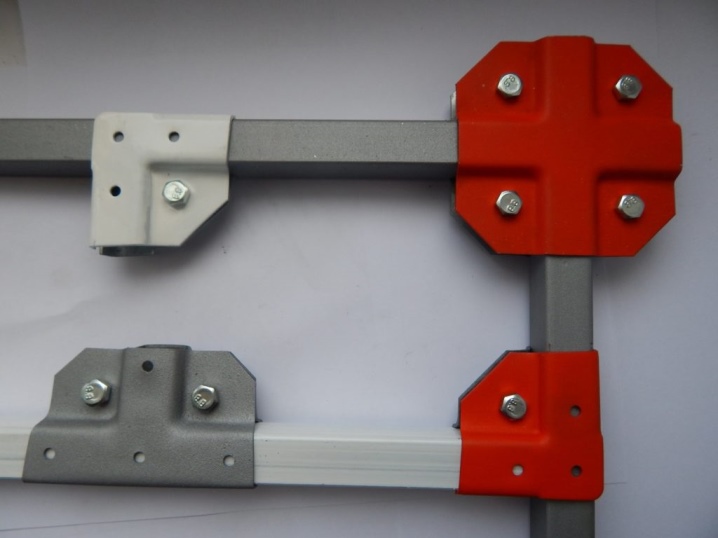

There are various types of crab format binders. So, T-shaped structures provide joining of 3 pipes of insignificant section at once. Installation with such a device is very simple. The L-shaped design is also used, which ensures the fastening of a pair of pipes at the corners of the buildings being formed. And X-shaped connectors provide reliable joining of 4 pipes at once, located in the middle of the assembly being formed.

Along with galvanized metal, products coated with a specialized composition can be used. Two separate blocks are bolted in one way or another. "Crabs" of the described species are used for pipes ranging in size from 20x20 to 40x40. Since the strength of the assembly being created is not high, it will be very easy to remove the pipes from the mount. On the street, the "crab" will need to be constantly tightened to avoid skewing.

The difference between "crabs" is related to the number of levels. The 1-tier type guarantees an extremely strong connection of the frame profiles. Strict perpendicularity is ensured between them. Importantly, the assembly of steel structures is simplified. This is especially typical for extended sections, where it is required to install many bridging elements, achieving maximum strengthening of the battens.

Special barbed details increase the stability of the joints; single-level devices allow you to decorate the gypsum plasterboard surfaces of buildings located in the same plane.

But two-tier solutions can also be used. Butterflies are P-shaped staples. For their manufacture, zinc-coated sheet steel is used. The sides are equipped with special hooks, which makes it possible to mount the frame of multi-level ceilings. In production, such a connector is made flat, bent into the desired shape immediately before use.

How to position and fix?

For the installation of "crabs" to be effective, everything needs to be carefully calculated. Otherwise, the high strength of the structure and its durability are unattainable.

Correct installation involves drawing up drawings. In accordance with the drawn up schemes, it is necessary to mark the surface to be treated. To install the fixing "crabs" correctly, you will have to take into account that their fixation points must correspond to the joining points of the elements (sheet materials and not only).

"Crab" devices are mounted using special screws. They have a cylinder-shaped head. Fasteners are equipped with a pointed tip. When they are twisted, the metal breaks through. In this case, the edge loses its original flatness and bends inward.

In addition, you will have to bend the whiskers, screw the hardware. But this is done strictly after the fastener itself is snapped onto the frame. Layout the plane and calculate the required number of nodes should be led from the center point to the edge, and not vice versa. Method of fastening products with a single level:

-

orientation of fasteners with technical tabs down;

-

stringing on a metal profile;

-

bending of the paws and their attachment by "klopiki" to the main profile;

-

insertion of bridging parts inside the "crab" until they click;

-

fixing these jumpers with screws;

-

attaching other elements.

To connect something using two-level "crabs", you need:

-

attach bearing profiles to the main ones;

-

give the used product the shape of the letter P;

-

stick it over the main profile until you hear a click;

-

press into the regular position with self-tapping screws;

-

put the guide bar at an angle of 90 degrees to the main bar;

-

insert the hooks into the profile grooves.

Attention: the antennae must be lowered as carefully as possible. With too much force, metal can be broken.

Watch a video on the topic.

The comment was sent successfully.