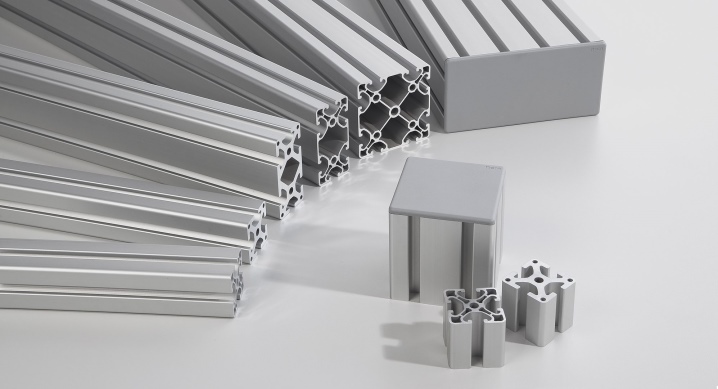

Structural profile: varieties and applications

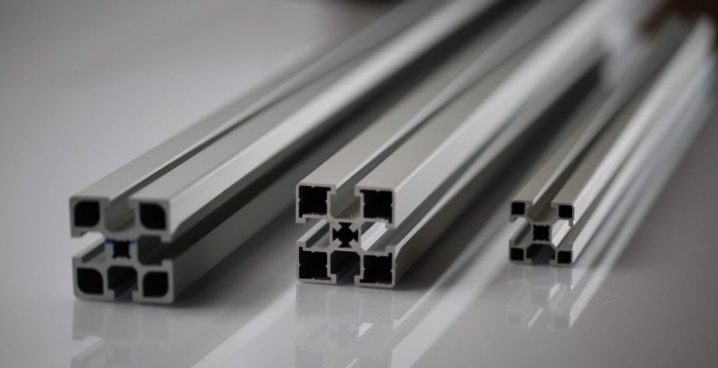

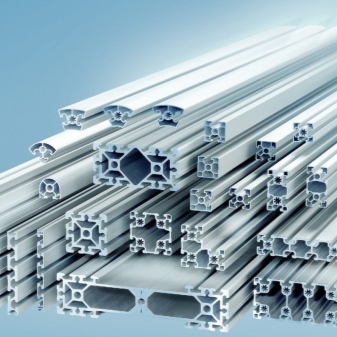

Structural profile is a very complex and multifaceted concept, there are many varieties of it, differing in scope. So, steel machine tools, plastic and other profile options are widely used, used in various joints along with nuts. Consumers should know everything about products measuring 20x20 mm, 40x40 mm, 90x180 mm and other sizes of such blanks.

Peculiarities

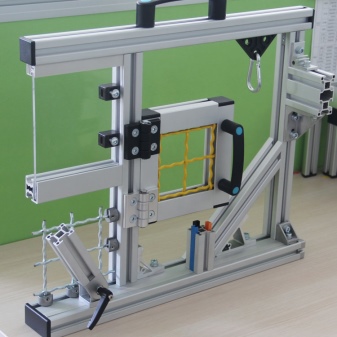

You don't have to be an engineer or a technician to understand that modern industry requires ever faster and more dynamic technologies. Wherein acceleration of production manipulations should not in any way affect the economic efficiency of work and the quality of finished products. One of the answers to such an ambiguous challenge is precisely the machine tool structural profile. However, this product is much more versatile than it might seem at first glance. The profile is obtained from either aluminum or steel; both options have advantages and disadvantages.

Technological and operational parameters of structural products are in any case clearly better than those of “simple” type profiles. These products are versatile. They can be used to make both the production machine itself and a technological fence that isolates it from strangers. But the main advantages are not limited to that. So, in comparison with the use of a standard profile, the weight is reduced by 31% on average.

If usually some mechanism or unit weighs 200 kg, then after the transition of manufacturers to a structural profile, this figure will decrease to 134 kg.

Of course, all operators and other users will immediately appreciate this benefit. The assembly will be faster, practically on the same principle as the well-known toy constructor. And also worth noting:

-

no need for additional work (there is no need to apply a primer, paint, make an exact fit);

-

the ability to install without the use of welding;

-

the simplicity of changing the design, adding other parts, removing and adding individual sections (therefore, the structural profile did not replace the traditional one only because of the high price).

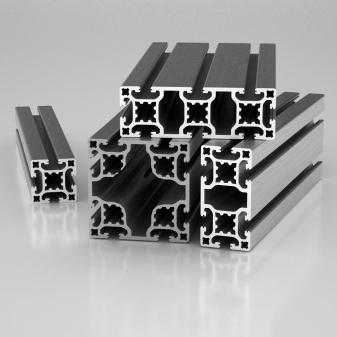

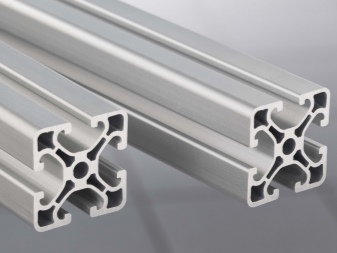

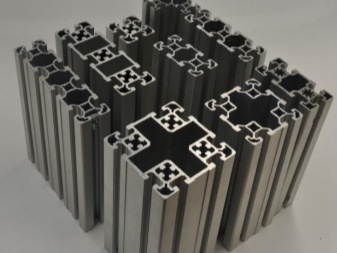

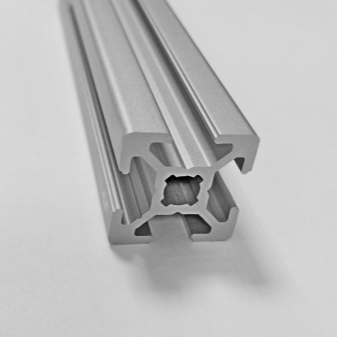

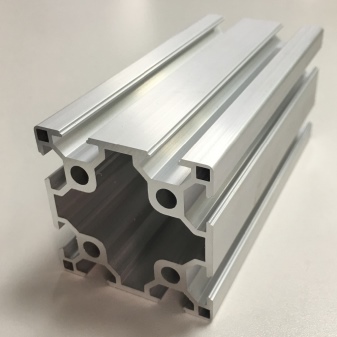

The unique balance of strength and lightness is achieved very simply. The internal hollow structure significantly reduces weight per linear meter. And the parallel walls solve another problem - providing excellent mechanical properties. Ribs contain twisting and breaking forces. The difference between the materials of the profile blocks fully explains the specifics of their application.

Dimensions and materials

Any structural profile is a pipe with a strictly defined shaped section. Product geometry may vary. However, in most cases, for practical reasons, rectangular and square designs are used. To make a profile, sheet metal is pressed. This technique guarantees excellent strength and reliability characteristics of the finished product.

The steel structural profile is lighter than its aluminum counterpart. You can reduce the mass by 20-30%. Ductile aluminum allows the use of pressing equipment without breaking the structure. It is highly resistant to corrosion, which is not typical for other metallic materials. In many cases, a shiny surface is quite beautiful even without additional staining.

On the basis of aluminum, you can create a variety of forms of structures. They will be equally good in industrial and civil engineering applications. The width of the workpieces mainly varies from 120 to 180 mm.

In particular, finished products can be up to 90x180 mm in size. The exact length is determined by the length of the receiving tables of the production equipment; if necessary, this indicator is adjusted.

The aluminum structural profile can also be anodized, and such a product is very much appreciated. In production, anodizing is carried out using sulfuric acid. As a result, the most beautiful surface is obtained, suitable for the formation of an individual design. Anodic treatment is guaranteed to prevent delamination and corrosion under the film. Products based on the machine profile are easily modified, self-aligned during installation, therefore, the reliability of the design does not cause any particular complaints.

An important difference between structural profiles is their shape. It is usually classified according to its similarity to one or another Greek or Latin letter:

-

"Pi";

-

"omega";

-

T;

-

L;

-

F.

Each of these types is intended strictly for a particular use. Thus, the "pi" profile becomes an excellent plug when assembling the product. With the help of "omega" panels can be assembled and joined together. The shape of the letter "T" is considered to be the optimal performance for the cover, locking the joints.

Returning to the materials, it should be emphasized that if the length of aluminum profiles is always 3000 mm, then for steel models this figure can be another 2500 or 2700 mm.

Profile products can also be coated with powder paint. It is much more durable than other dyes and resists wear and tear. The choice of a specific color is always made according to the RAL catalog. In some cases, a film with a decorative pattern is glued to the profile.

Attention: when assembling the finished product, it is required to scrupulously follow the manufacturer's recommendations, otherwise distortions and warpage of the mounted panels are likely.

In some cases, structural plastic profiles are used. Their main area of application is the manufacture and installation of PVC and aluminum windows.

As for metal products, many of their manufacturers also produce reinforced models. The bottom line is that such a product can withstand very powerful loads with almost no loss of quality. Designers seek, above all, maximum reliability in terms of bending and torsional forces.

Models 20x20 mm are suitable for obtaining:

-

small architectural forms;

-

various components for cars;

-

parts for industrial equipment.

Products measuring 10x10 mm are undoubtedly lightweight. However, their strength and bearing capacity are questionable. They almost always try to choose more solid models. As for the 20x40 mm profile, it is optimal for situations with a moderately heavy load. Like other versions, this product is made primarily of aluminum.

In a number of cases, structural profiles are in demand:

-

40x40 mm;

-

30x30 mm;

-

60x60 mm;

-

45x45 mm;

-

80x80 mm.

Application area

This area is very broad. So, profile products are often bought to do:

-

boxes for electrical equipment;

-

vehicle radiators;

-

heating batteries;

-

conditioners;

-

home and industrial refrigeration equipment;

-

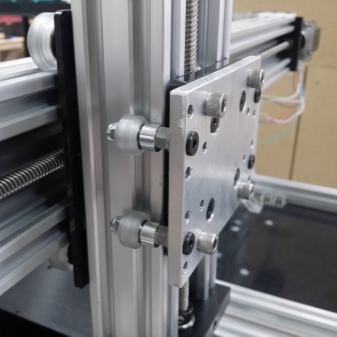

stands for industrial machine tools;

-

car parts;

-

products for aircraft construction.

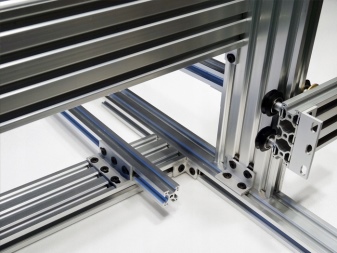

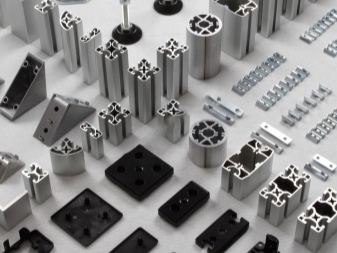

If the profile is used for construction and installation work, as well as in some other cases, installation is carried out using cage nuts in the shape of the letter "T".

They are inserted into the groove both from the plane and from the end. The fasteners are fixed by rotation. When connecting parts that form large structures, the fastening of individual blocks of the profile assembly is often carried out using corners. In addition to the areas of use of the profile already mentioned, it is worth noting more:

-

prisms and boxes for advertising, trade and exhibition needs;

-

obtaining a drawing profile for special orders;

-

decorative strips and guides;

-

electrotechnical tires;

-

boxes;

-

channels;

-

classic round pipes;

-

thresholds.

The comment was sent successfully.