Features of profiles for glass

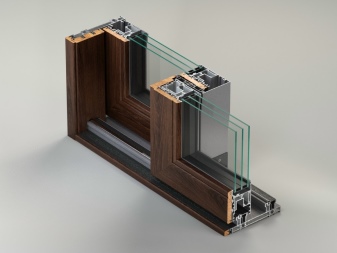

Modern interiors contain a lot of glass partitions and elements. The designers decided to use glass structures in order to distribute the existing space as functionally as possible. It is customary to use special profiles for framing and fixing glass sheets.

general description

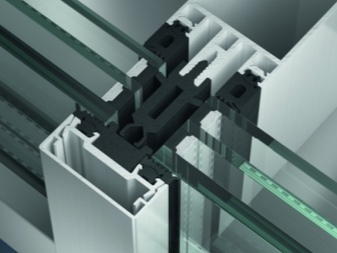

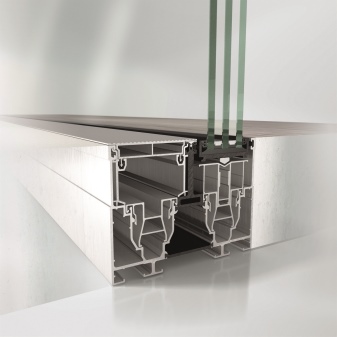

Glass profiles usually come in standard sizes and designs. On the base (most often it is metal) there are holes where the clamps are attached. They are located at a certain distance. The profile also includes clamping strips for fasteners and decorative snap-on covers.

The design assumes the presence of a guide bar and a clamping plate. Due to them, the glass can be fixed very securely. Decorative profile covers are usually ground, polished or anodized.

It should be noted that profiles can be polished (with a shiny surface) and unpolished (with a matte surface). Usually, the clamping profiles are also equipped with gaskets made of rubber or silicone.

They are needed to remove the resulting gaps. An obligatory part of the profile are also screws with a threaded plug and end caps to give a complete look to the entire structure.

The dimensions of the glass sheets determine the parameters of the fittings. For the installation of most glasses, a standard profile height of 4 cm is suitable. However, there are options with a large height, designed for large glass sheets.

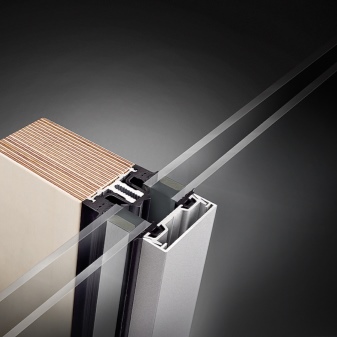

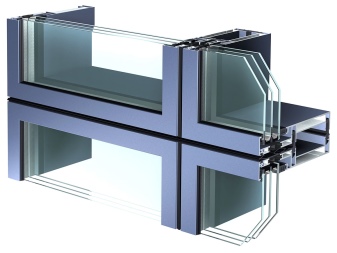

For glass interior partitions, you can choose a profile from any material, including silicone or plastic. But for facades, the aluminum option is better.

Such profiles are lighter, are resistant to corrosion and low temperatures, and are easy to process. It is undesirable to use aluminum profiles near electrical equipment, as they are excellent current conductors.

The profile is necessary for the glass structure to make it more rigid and reliable. They can vary according to use, design and style.

Species overview

For glass partitions to please, it is important to choose the right type, as well as the type of profile. By type, designs can differ in:

-

upper;

-

lower;

-

finishing;

-

end.

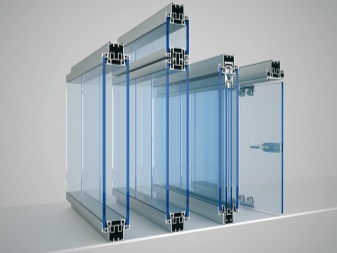

The frame profile has become very widely used, since it is used as a furniture, facade, support. The connecting or sealing option is most often used for sliding doors or dressing wardrobe rooms. As for the types of the most commonly used profiles, there are several main options.

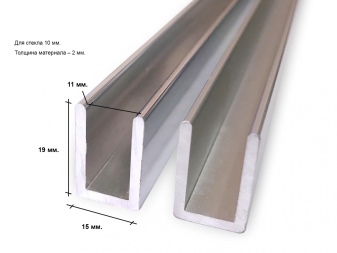

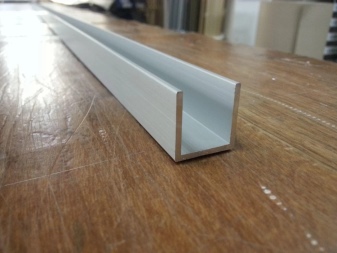

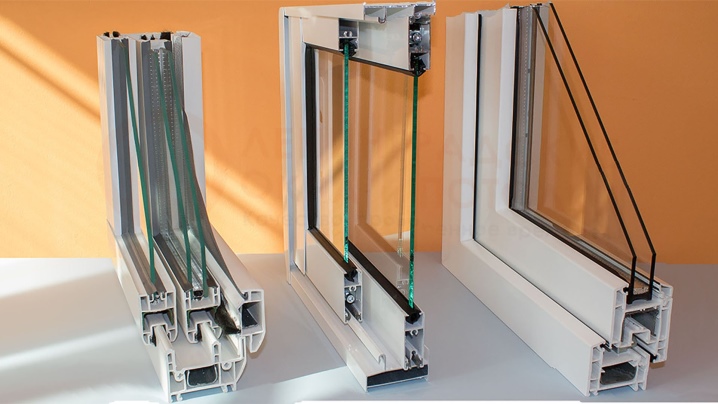

U-shaped

They are the simplest of all known. The structure consists of two profiles with different dimensions. As a rule, a smaller one (lower) is attached to the floor, and a larger one (upper) is attached to the ceiling. A special material is used for sealing on both sides. Most often, rubber seals are used, which provide reliable fixation of the glass and reduce friction between the sheet and the profile.

The U-shape is characterized by increased rigidity, reliability, durability and convenient use. Such structures can be placed around the perimeter of the glass sheet in order to protect it as best as possible from various mechanical damages. Suitable for attaching glass bags to the wall.

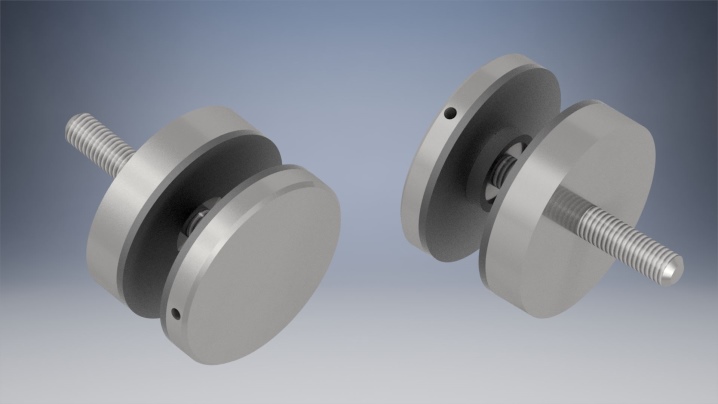

Point

They consist of two rulers located at the edges, connected by a rod. Installation of this type of profile involves making holes. Plastic elements are then inserted into them and fixed with bolts. To make the finished design look more attractive, plugs are used.

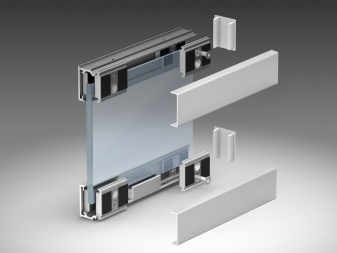

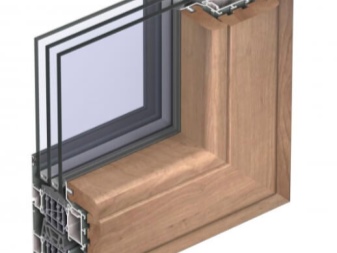

Clamping

The design of the clamping profile includes a strip, fastening elements, decorative latches. This type is universal, and most often it is used to fix the glass sheet in an upright position. Suitable for mounting the partition in the floor or ceiling.

The glass is fixed thanks to special strips. In some cases, the profile is fastened along the entire perimeter of the web for greater reliability. The structure can be used for both indoor and outdoor decoration of the building. Great for residential interiors, business centers and shopping malls.

The clamping (docking) type of profiles can differ in a number of parameters.

-

By the thickness of the glass sheet... There are options for both thin sheets of 6 millimeters and massive ones of 20 millimeters.

-

On a polished or unpolished (matte) surface. The polished version looks more aesthetic, it can be anodized.

-

By application: inside the building (non-anodized) and outside (anodized).

Materials (edit)

Profiles for glass partitions are often made from the following materials:

-

metal;

-

wood;

-

PVC.

The metal version is usually made of stainless steel or aluminum. Moreover, the latter material is preferable. This is due to the fact that it is more reliable, has less weight, does not corrode. It should be noted that the aluminum profile can be clamped or U-shaped. Among the advantages of aluminum, it is also worth noting ease of processing, smooth surface and resistance to various damages.

Steel profiles are heavier than aluminum ones, but they last much longer. In terms of price and quality ratio, this type is optimal. However, it should be borne in mind that they are less flexible than aluminum.

Wood profiles attract with their appearance. For additional protection against moisture and dust, the wooden structure is covered with a layer of varnish. Currently, this design of glass sheets is very popular due to environmental friendliness. As for the service life, it averages 15 years. The disadvantage of a wooden profile is its high cost.

The plastic profile is similar to the design for plastic windows. It should be noted that PVC is non-toxic. The main advantages of this material are the variety of colors, ease of care and low cost.

A silicone profile is very rare. It is mainly used as a sealant. Most often presented as a transparent option.

Dimensions (edit)

The profile dimensions directly depend on the thickness of the glass sheets. For example, for the thinnest glass planes of 6 millimeters, constructions with a section of 20 by 20 millimeters and 20 by 40 millimeters are used. He usually has 4 grooves on each side, designed to cross the partitions. The profile of this size is used for dividing space into zones, for example, in large offices.

Glass with a thickness of 8 millimeters is better at muffling sounds. For them, profiles of a slightly larger section are used than for 6 mm sheets. This is due to the fact that they need more rigidity due to their increased mass.

Glass sheets with a thickness of 10 millimeters require the use of a profile with a minimum cross-section of 40 by 40 millimeters. This option is suitable for a single-layer glass partition. If there are two layers, then it is worth choosing a size of 40 by 80 mm, three - 40 by 120 mm, four - 40 by 160 mm.Such structures are widely used wherever it is necessary to provide good sound insulation - in offices or in residential premises.

For the thickest sheets of glass with a thickness of 12 millimeters, a profile should be selected with a cross-sectional edge starting from 5 centimeters. For single-chamber packages, the cross-section will be 50 by 100 mm, and for three-chamber packages - 50 by 200 mm. Often, such massive structures can be presented in different colors.

Selection Tips

First of all, when choosing a profile, they are repelled by the style of the interior.

For example, for strict classics, black, as well as neutral tones, will be an excellent option. For an informal design, you can use the multi-colored profile views. This will allow you to create original compositions and at the same time harmoniously combine them with the general style of the space.

In addition, it is important to take into account other nuances as well. One of the most important is the cost of the profile. For example, U-shaped types are cheaper than clamping ones. However, it should be borne in mind that the first option is suitable for blind structures, without opening. Clamping profiles are more versatile and are used not only for installing glass partitions, but also for doors.

Fastening accessories are constantly being improved and selected depending on the type and type of profile. This is due to the fact that some models may have limitations in use.

Installation features

Profiles are usually assembled in factories with special equipment. In order for the frames to be of high quality, all parts should be very carefully and accurately mounted. At the same time, it is important to monitor the observance of an angle of 45 degrees when trimming corner joints. If you get some skills, then you can install the profile yourself. To do this, you will need corner fasteners, self-tapping screws and a suitable sealant.

Usually the glasses are installed in the profile at the assembly stage. However, sometimes the glass sheets can break and have to be replaced.

An important point when installing with your own hands is drilling accurate holes in the profile. For this, a special template is used that allows you to maintain the required angle of inclination in relation to the center of the drill.

The assembly is done in a specific order.

-

The glass unit must be installed in the groove.

-

After that, when using rubber gaskets, seal it around the entire perimeter.

-

Then install a glazing bead to seal and secure the glass assembly. Moreover, it is still necessary to seal the connection.

-

If the glass is damaged and needs to be replaced, then all actions are performed in reverse order. Then the glass sheet is changed to a new one.

For fastening the profile, depending on the material from which it is made, special fittings are used. Today, a wide range of parts is presented on the market that allow you to mount and connect frame assemblies, hinges, latches and other elements. It is worth clarifying that different products require their own fittings for connection. Of course, there are universal accessories or alternative ones in the form of self-tapping screws or other available items.

The comment was sent successfully.