Aluminum profiles for glass

It is rare to find modern interiors that lack glass. And we are not talking about the usual windows and loggias with glazing. In recent years, dividing a small space with glass partitions and other types of introducing transparent surfaces into rooms has been gaining popularity. The best solution for framing fragile glasses and their secure fixation are aluminum profiles.

Description and scope

Aluminum profiles for glass are best suited for creating a solid and reliable package from many glass sheets. The main advantage of such a lightweight and durable metal element is its low cost, especially when compared to stainless steel. In addition, the aluminum profile is environmentally friendly and aesthetically pleasing.

Conveniently, if necessary, the metal can be processed directly on site. This allows you to create a variety of glass and aluminum structures.

And do not dwell on the classics, you can look for more original options.

The aluminum profile makes it possible to create cozy corners in the apartment and houses, in particular, it is great for decorating partitions. Due to the different number of grooves in the profile, you can choose the degree of sound insulation.

Aluminum, like metal, is a light and flexible material, but in the form of a profile it becomes quite rigid, making it suitable for fastening large and heavy sheets of glass. Structures of this type are used to decorate the front entrance, showcases, and also other places where abundant glazing is required. Directly in housing, glazing is less common and then only as partitions.

For a greenhouse, an aluminum profile can be used, but it is worth considering a number of its disadvantages. Among them is high thermal conductivity, which heats the frames excessively in summer and cools too much in winter. As a result, at low temperatures, condensation can form on the bags. Also, aluminum is prone to corrosion under the influence of chemicals. Soundproofing is not strong enough to protect against outside noise.

Of course, there are many advantages to aluminum profiles. For example, structures are capable of partial air passage. This allows the interior spaces to be ventilated. Also among the advantages is fire safety, resistance to deformation and destruction, long service life (up to 80 years). If desired, the aluminum surface can be decorated with any coating.

The metal is widely used both in private houses and for decoration of various commercial premises, for example, shopping centers. Such a profile is no less popular for framing plexiglass on advertising structures.

Quite often you can see aluminum and glass structures in offices, airports and in the interiors of other large premises.

Species overview

Aluminum profiles are most needed for framing thin glass sheets with a thickness of 4 mm or more. For example, with a thickness of 6 millimeters, profiles with a section of 20 by 20 mm and 20 by 40 mm are used. They, as a rule, have four grooves on each side. In theory, such a groove allows the partitions of four rooms to intersect. The 6mm profile is well suited for dividing work areas in large office centers.

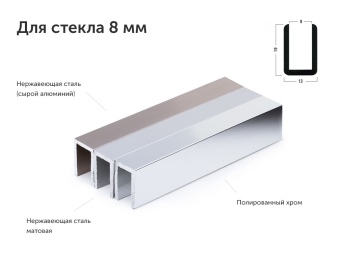

For glass with a thickness of 8 millimeters, profiles with a large cross-section are used to ensure increased rigidity. This is necessary because thicker sheets weigh more. In this case, the dimming is similar to what can be observed in the 6 mm version.

A glass thickness of 10 millimeters requires a significantly different profile. So, the side of the section must be at least 40 millimeters in order to withstand the entire mass. Also, the structure must withstand various vibrations and be more rigid. Of course, it is best to choose options with a size of 80 by 80 millimeters. They will even allow you to create glass walls that can shield, for example, from the sound of a working TV.

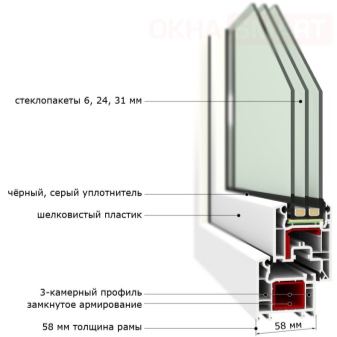

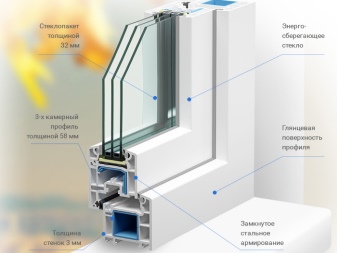

Various aluminum profiles are available for framing 12 mm glass. For example, a profile thickness of 100 mm will allow you to create a single-chamber double-glazed unit, and 200 mm - a three-chamber one.

Such partitions are suitable for good sound insulation and are most often made of opaque glass.

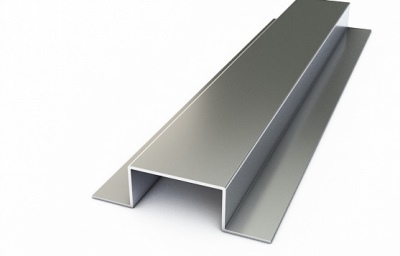

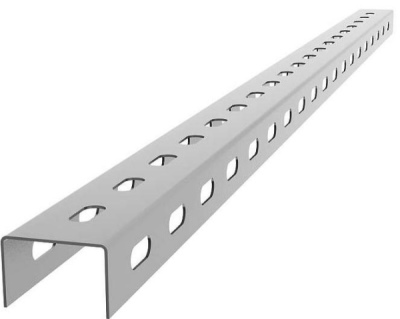

U-shaped

They are often called channel bars and are used to create frames for internal glazing. They are also often used as a basis for framing the end of a building for aesthetic purposes.

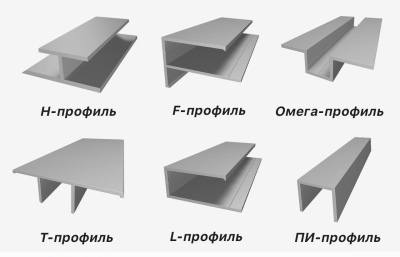

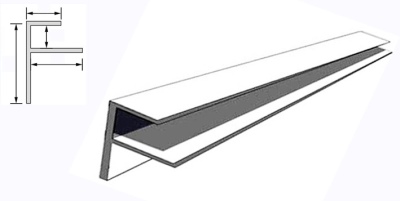

H-profiles

This type can most often be found when decorating partitions in an office space. In addition, such elements have found their application in the design of various furniture, lamps and other structures for decoration. In the form of the letter H, the profile allows you to connect sheets located in a single plane, for example, for a kitchen facade. It can also be used as a profile suitable for fixing several glasses in one frame.

F-profiles

Designed for those places where the glazed structure must be tightly adjacent to some other plane. Quite often, such a profile is called a pressure profile.

Other

U-shaped makes it possible to create ends of elements on facades. As a fastening element, profiles are most often used that resemble the letter R.

Corner profile views, similar to the L symbol, are required for attaching to canopies and building facades. Tavr or T-type is a fastener for panels on the facade. Also, among the types of profiles, it is worth highlighting the radius profile with insert plastic elements.

On the same level, elements can be fixed to each other using a Z-profile, and reinforced from the outside of buildings with a D-profile. Small holes are blocked using the W-shaped type.

Installation features

Usually, the installation of the profile takes place in special industries, where all the necessary equipment is available. When assembling frames, it is important that all parts are connected properly. In particular, corner joints must be accurately trimmed at a 45 degree angle. Of course, if you acquire some skills, you will be able to assemble the package yourself. In this case, you can connect using corner elements, self-tapping screws and a suitable sealant.

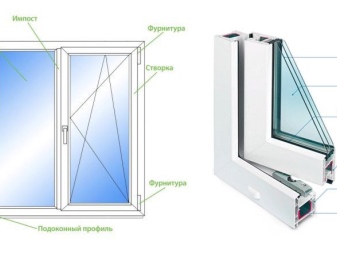

The installation of the resulting packages is carried out using the same technology as the installation of ordinary plastic windows. First, a box is installed with alignment along all axes, horizontal and vertical planes. After this, a temporary fastening is made using wedges.

Next, the frames are hung, in which it is important to check with what accuracy and how tightly they fit. Also, in a timely manner, you need to make sure that the fittings are working. It is best to fix the package with anchor bolts, followed by filling the gaps with polyurethane foam. Then slopes, bumpers for precipitation and other additional elements are made.

The installation of the profile and glass is carried out in the following order:

- a glass sheet or one-piece glass unit must be installed in the groove;

- then a seal should be carried out, for which special rubber gaskets are used;

- after that, it is necessary to put a glazing bead for sealing and securing the glass assembly, as well as sealing.

If you have to replace the glass unit, then all procedures should be carried out in the reverse order. Then install a new one. There are various frames that are designed to hold the glass sheet in the aluminum profile, according to certain technologies.

In order for independent work on the installation of the profile to be successful, it is necessary to adhere to some rules. It is worth starting with a careful examination of the entire frame structure in order to understand how the glass is removed correctly.

For fastening the metal profile, use only special fittings. There are many different elements that allow you to connect hinges, glass assemblies, latches and other parts. The connecting fittings consist of various components and are selected depending on the type of construction.

Of course, you can use alternative fasteners, such as self-tapping screws. However, this is permissible with self-assembly or with missing parts.

For partitions, it is necessary to choose a profile with a width of 3 to 6 cm, depending on the thickness of the glass and the number of canvases. In this case, the covering strip can have a width of 2 to 5 cm. TIt may also require 90-270 degree swivel pipes. Aluminum parts can be painted in any shade using polymer compounds. Corner posts allow the partition to turn in any direction.

Installation of swing doors is carried out using a profile with a thickness of 0.12 to 1.3 cm. In this case, the shape of the cross section will be very different. As an addition, corners, brackets, embedded elements, eccentrics are used. To make the sash look better in the interior, all parts can be painted using a powder composition, varnish or an anodized profile can be chosen.

Sliding canvases are created from a frame type or in the form of the letter T. They can be supplemented with overhead parts, handles, bottom and top guides.

Painting, as a rule, is done in a uniform tone with the main partition made of aluminum.

Aluminum profiles for glass in the video below.

The comment was sent successfully.