All about structural aluminum profiles

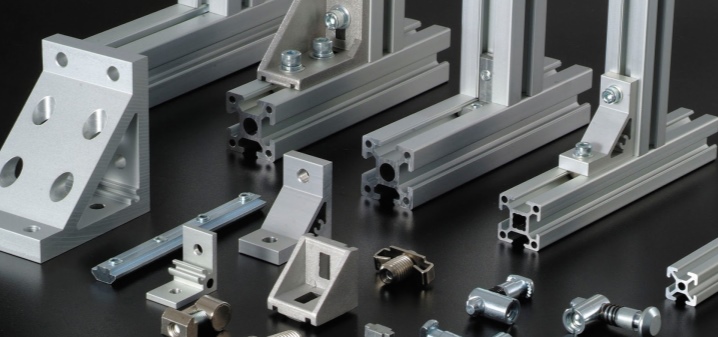

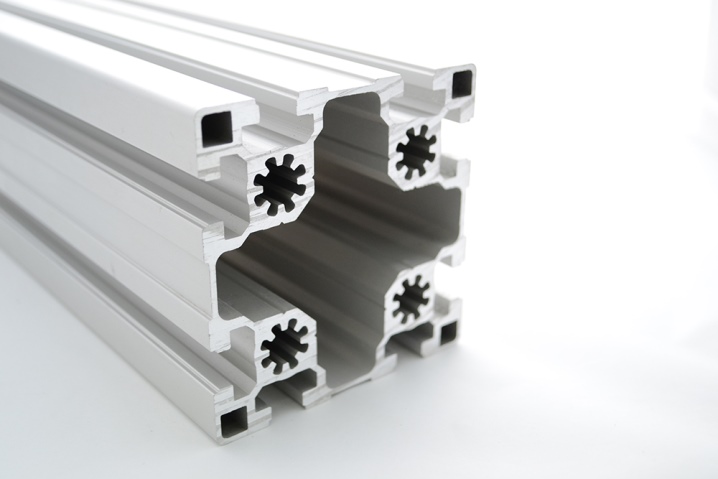

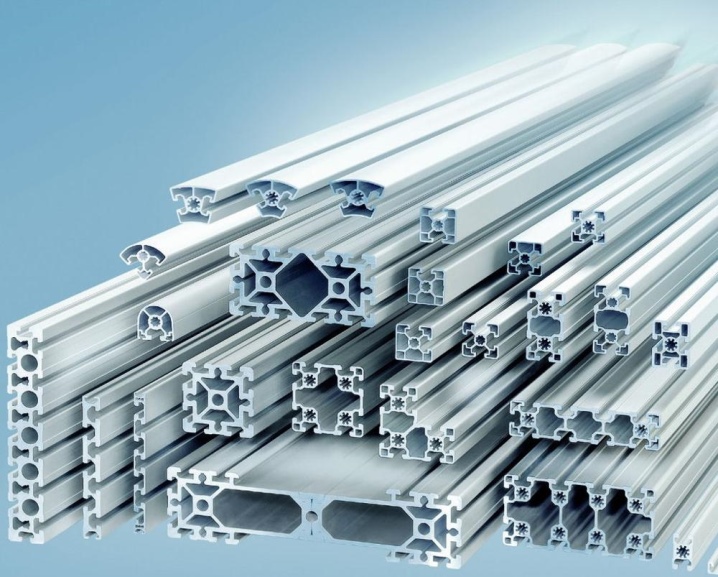

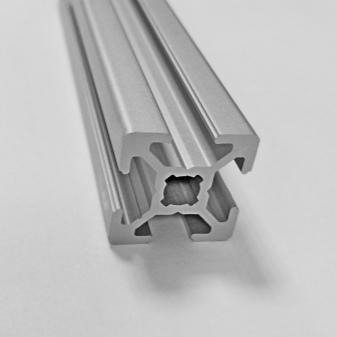

Quite a few people need to know everything about structural aluminum profiles. There are machine profiles (for CNC machines) 11x20 and 20x20, 30x30 and 40x40, as well as profiles of other sizes. Having dealt with their features, with the nuances of products from different manufacturers and areas of application, you can significantly improve your work in a workshop or in an enterprise.

Peculiarities

Machine-tool structural aluminum profiles have a number of attractive characteristics that lead to their very active and widespread use. Such products are present in the assortment of almost all companies. The benefits are associated with:

- high plasticity;

-

excellent durability;

-

comparative lightness (in this sense, aluminum clearly outperforms even the best grades of steel);

-

resistance to both very low and very high temperatures found in everyday life;

-

the simplicity of laying holes for pulling wires and connecting other necessary communications directly through the profile.

What are they?

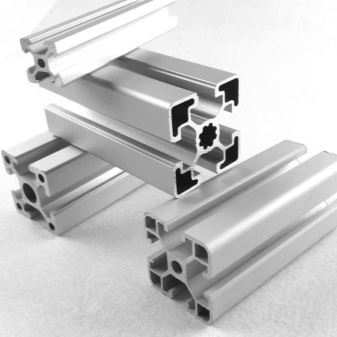

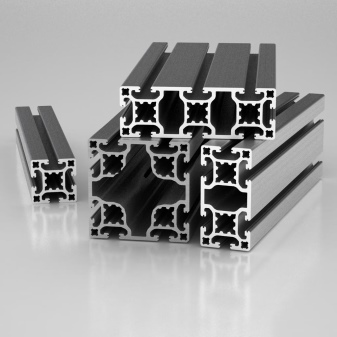

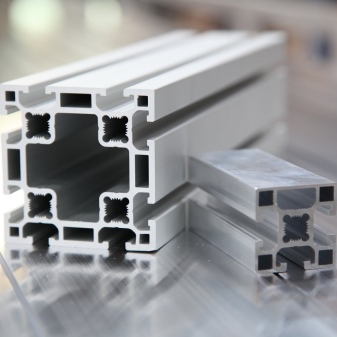

The main categories of aluminum profiles are described in standards 22233 and 8617. Hollow products are products with a void inside. Normative acts prescribe the equipment of such structures with at least one closed face, found in a cross-section.

Quite often, solid products are also used, which are devoid of closed areas. As for the free end, it can be found in both hollow and solid products.

Among the hollow profiles, there is also a semi-open - aka semi-closed - type. On one side there is a passage to the inside of the cavity. But it is important to understand that not all voids with an open passage belong to a semi-closed group. This requires that the area of the profile product significantly exceeds the size of the entrance. To obtain hollow and semi-open profiles, strictly identical matrices are used, divided into 3 types:

-

bridge;

-

cruciform;

-

porthole.

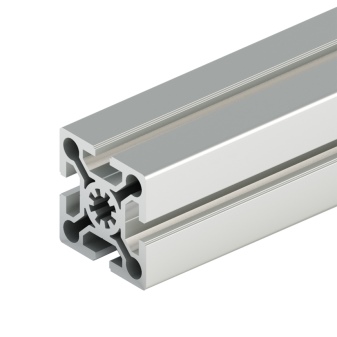

It is envisaged to use at least one weld seam located in the longitudinal plane. The molten metal will flow around the bridges, which improves frame support. It also accurately shows the inner contour. During the welding process, aluminum is affected not only by significant temperature, but also by significant pressure. To create solid profiles, solid matrices are used that have a disk-like shape; holes are made in the disc.

Anodized aluminum is often used to make structural profiles. The anodic coating provides quite reliable protection even against difficult environmental conditions.

This property is perfectly manifested in coastal regions, where the harmful effects of salty air are undoubtedly. It is also appreciated in large cities, which are also saturated with a number of hazardous components in the air. It is a pleasure to paint the anodized surface; but for these benefits you will have to pay in the truest sense of the word.

The reinforced structural profile works even under very high mechanical stress. It is also willingly taken for the construction of capital industrial buildings. As for the external geometry, it is customary to distinguish:

-

frame;

-

U-shaped;

-

L-shaped models.

The frame version is taken to decorate the openings of a door or balcony. Sometimes it is also used as a decorative element. A profile in the format of the letter P turns out to be a support for the installation of a heavy slab.Compared to frame models, the latter have a noticeably wider width. The narrowest edge in most cases is the top or bottom edge.

The profile in the version of the letter G turns out to be an edging for decorative items. Sometimes it is also used to separate inconsistent design options. The cold-formed block is notable for the method of production. The thickness of the strips does not exceed 4 mm. As for the extruded profile, it is additionally divided into hardened and aged groups.

Dimensions (edit)

One of the most popular sizes is 20x20. It is present in lines from almost every manufacturer. But still the dominant role is played by 40x40 profiles. Often, such products are produced according to a lightweight scheme. The strength and rigidity will still be definitely higher than that of 11x20, 20x40 or 30x30 products.

Modern manufacturers, of course, are promoting other models as well. If the size 25x25 seems too small, then you can use, for example, products 20x80. They are often tubular. But there are also other versions. So, the 45x45 model will perfectly cope with rather serious loads.

It is possible to make machine beds, industrial fences, and shelters for transported equipment. Such a product is more expensive than 40x40, but its perfection is beyond doubt.

A number of manufacturers also offer 45x90 profiles. They are suitable for load-bearing and moderately loaded structures. Such products are a weighty alternative to all of the above dimensional positions.

You can also buy profiles in sizes:

-

40x80;

-

50x50;

-

60x60;

-

80x80.

Popular manufacturers

Products of brands are in demand:

-

"Alumika";

-

RSI;

-

BK-ALPROF;

-

Tatprof;

-

Alvid;

-

Alsib;

-

Alsit;

-

"Yug-Profile".

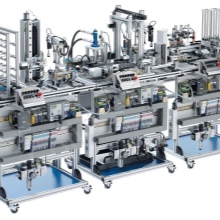

Applications

Structural aluminum profiles are used for:

-

for CNC machines;

-

for conveyors in the food and pharmaceutical industries;

-

for the manufacture of warehousing products (carts, containers, shelves, racks);

-

in the preparation of trade showcases and racks, their exhibition counterparts;

-

in the production of structures for advertising and information purposes (first of all, stands and boards that are resistant to the action of the external environment and look beautiful from the outside);

-

to obtain beds, various measuring and control devices;

-

in the production of guides for industrial robots and fixation of precision instruments;

-

for a table and other types of cabinet furniture;

-

for the construction of facades and partitions on construction sites with an attractive appearance and excellent load-bearing capacity, amenable to facing with randomly selected finishing materials;

-

for the manufacture of stairs (including stepladders).

The comment was sent successfully.