Repair of a building hair dryer

A hair dryer is not the cheapest equipment, so repairing it can be expensive for the owner. However, it is worth trying to repair the device yourself at home: its design is not particularly difficult.

The article tells about possible malfunctions of a building hair dryer and methods for eliminating them yourself, without contacting a service center.

Causes of breakdowns

Let's consider the most common reasons for the technical nature of the hot air gun, due to which the device stops working.

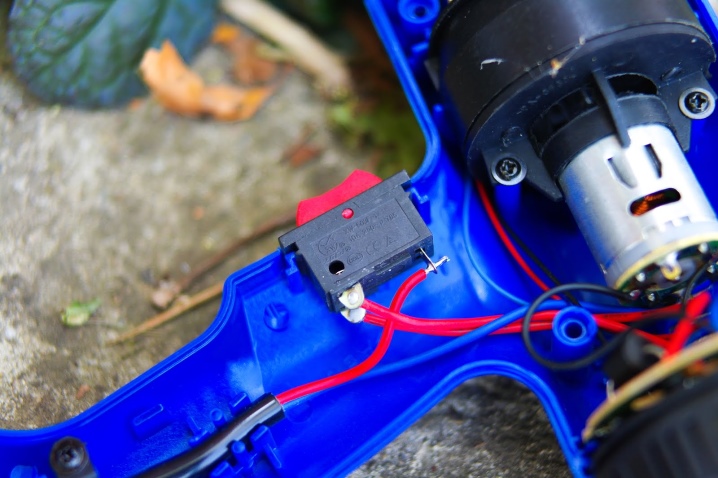

- Buttons and switches. These elements often jam, which is why the electric current does not have the ability to freely pass through the contacts. This is due to the appearance of carbon deposits and the formation of oxides. It is enough to disassemble the hair dryer and clean all connecting contacts that have rust or other plaque. In some cases, replacing the switch will bring the instrument back into service.

- Mains wire... Mechanical damage to the wire can form, for example, as a result of crushing it with something. In addition, prolonged operation of the hair dryer at high power also renders the wire unusable over time. Visually, such faults are not always visible, since the damage is inside the wire (the core burns out, the contacts weaken, and so on). Breakdowns in this part can be diagnosed with a multimeter by ringing the cord. An elementary replacement of the mains wire will restore the work of the hair dryer.

- Collector motor... In this case, a multimeter is also useful. The electric motor is defective, when a clicking sound is heard when ringing or a cut is heard. It may fail due to poor-quality assembly (then the engine cannot be repaired) or clogging of the connecting parts (cleaning them again will allow the device to work normally).

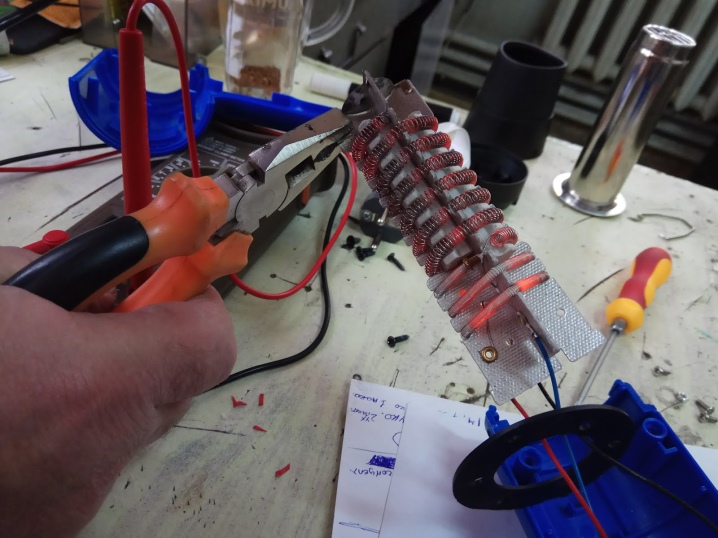

- Fee and spiral. To see if the cause of the malfunction is the burnout of these parts, the heating element must be removed from the metal case. In addition to visual inspection to detect oxidation of contacts or their disconnection, resistance must be measured with a multimeter. A zero indicator on the device indicates a violation of the integrity of the nichrome thread. Due to the intensive use of the hair dryer, the nichrome thread loses its capabilities over time, becomes more fragile and makes other components of the device unusable. It is the board and the spiral that fail in the first place.

How to fix it?

Before repairing a building hair dryer with your own hands, you need to make a diagnosis. After determining the cause, you need to arm yourself with a screwdriver and, possibly, a soldering iron. For example, you will have to solder the disconnected wires when replacing the coil.

If you need to replace the capacitor, choose a new element with the same power, and also taking into account the nominal voltage value. Not all parts of a hair dryer can be repaired: for example, the external wire is usually replaced with a new one. To do this, disconnect it by opening the case, and attach a new cord. Before fixing the bolts on the case, they check whether the device will work with a new wire, for which it is necessary to turn it on. After making sure everything is in order, you can start assembling the case.

In general, repairing a construction hair dryer does not require special knowledge: you just need the desire and ability to handle an elementary tool.In addition, safety precautions and safety precautions should be followed when repairing the power tool. All manipulations for diagnostics, finding places of malfunction, as well as the repair itself, are carried out with the device disconnected from the network.

Expert advice

When the hair dryer stops working, experts advise to disassemble it in any case, even if the reason is clear and visible. It is better to carry out a complete diagnosis of the device.

And then in order to assemble it correctly, it is better to photograph the location of all the mechanisms and parts inside the structure.

Those who are friends with schemes and know how to draw them can use their abilities by fixing the arrangement of mechanisms on paper, but this is more difficult than photographing. Having a camera close at hand these days is not a problem: every smartphone has one.

When you turn on a working hair dryer in the network, the engine emits a characteristic sound - even and not very loud. If the device creaks, cracks, rustles unevenly, or there is no sound from it, experts advise you to immediately pay attention to the engine - it is quite possible that the problem of the hair dryer malfunction lies in the main mechanism.

Experienced people recommend that when eliminating breakdowns inside, disassemble the hair dryer completely in order to carry out preventive actions with respect to all mechanisms of the unit. It is quite possible that a number of weak points will become clear, for example, weak or dirty contacts, deformed elements and parts that are about to fail.

As they say, since the device has already been disassembled, it is better to carry out diagnostics more thoroughly and, if necessary, update the design. Observing the sequence of actions, listening to the opinion of experts, you can independently repair your own building hair dryer, and not look for a specialized center for the repair of such equipment.

Equipment often fails due to improper operation... So, before connecting to the network, you need to pay attention to the fact that the cord is not twisted, otherwise creases will appear.

It is imperative that you familiarize yourself with the manufacturer's recommendations: how long the equipment can be in operation continuously, how to take care of it, where to store it.

The comment was sent successfully.