All about scaffolding assembly

Scaffolding has long proved to be very convenient and practical structures that are used in many types of work. They are collected from different materials. The forests themselves are subdivided into several distinct types. In this article, we will learn everything about assembling such structures.

Fundamental rules

Scaffolding is used to simplify many types of work. They are often made by hand, since there is nothing prohibitively complicated in these structures.

However, building structures of any type must always comply with a number of basic rules that are dictated by safety issues, as well as the recommendations prescribed in SNiP.

Consider what requirements will need to be met in order to mount a high-quality and safe scaffolding structure.

- First of all, the craftsmen who will mount the scaffolding must carefully understand all of their features. It is necessary to take into account all the stages and nuances of the assembly of the selected structure, as well as the features of the building.

- The site intended for the installation of the structure must be thoroughly cleaned of debris. It needs to be aligned. The soil will need to be properly compacted and equipped with special drainage devices.

- The individual parts of the scaffolding are usually raised and then lowered with the help of special equipment.

- All fasteners, floorings and screeds of the fences of the structure must be installed in series. The enclosing frames will need to be fixed only strictly in accordance with the plumb line.

- In order for all installation work to be as safe as possible, the scaffolding must be securely fixed on the wall of the building in height. The decks must be flat enough, laid strictly horizontally. Only if this simple rule is observed, workers can not be afraid for their own safety and the level of convenience during work.

- Workers during the installation or finishing work must necessarily go up and down from the scaffolding on a reliable ladder. Other methods of ascent and descent may not be the safest and most comfortable.

- Dismantling of the structure in question should be carried out in the reverse order. It is advisable to disassemble the structure only after all building materials, debris and tools have been removed from the scaffolding.

The scaffolding installation rules are simple and binding. The reliability and safety level of the future design will depend on this.

Component overview

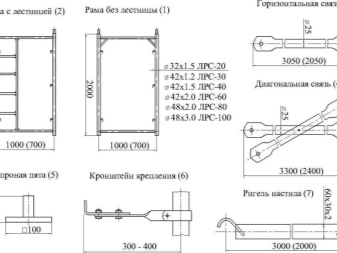

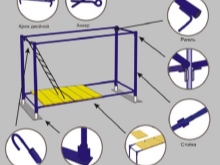

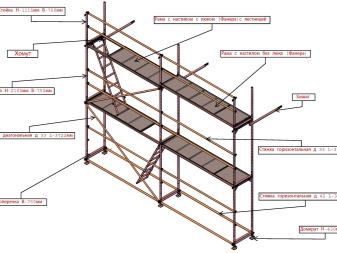

To assemble a reliable, stable and strong structure, the master must have a certain supply of component elements, from which scaffolding will subsequently be made. Let us consider in more detail which elements will be needed to carry out such work.

- Strong uprights. They will take on the main load. They are placed on a prepared site, after which all other necessary structural elements are attached to them.

- Spacers that can be placed diagonally or horizontally. These elements subsequently serve as connecting nodes for the racks. With their help, the entire structure is made stronger and more stable.

- Lintels on which the boardwalk will be exposed in the structure. Typically, their width is from 1 to 3 m. The height of the tier primarily depends on where all the installation work is carried out.Basically, this parameter is 1.8-2 m.

- Stops are very important details of the future design.... They are necessary so that the structure can stand evenly and reliably on the prepared ground.

- Stairs, along which masters will be able to safely and easily climb up or down from the scaffolding.

- The necessary fasteners with which all elements of the structure will be connected to each other. Often, a special fastening component is used to assemble the products in question - a ring screw or a welded hook.

- If the structure is planned to be made adjustable, screw supports are used.

To ensure that workers, construction materials and tools are secured against falls from the scaffolding, a strong facade mesh is stretched from the front side. If the hammer unexpectedly falls into the gap between the mesh and the horizontally exposed pipe, it will not harm anyone.

The mesh fabric also effectively protects against the aggressive effects of sunlight, rain, snow. It is much more comfortable and easier to work with such an element than without it. A significant drawback of the mesh is that it certainly begins to accumulate and retain dust in itself. It is better to remove the mesh while sanding the facade surface or when working with toxic components and use respirators for additional protection.

Scaffolding schemes

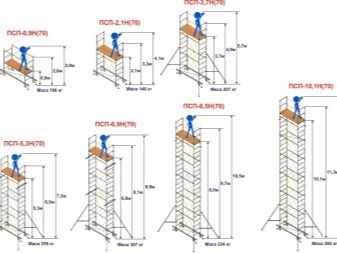

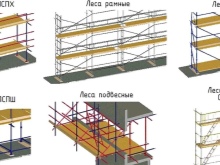

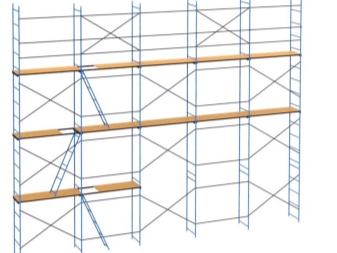

Scaffolding is classified into several types. They differ structurally. Each of the options can be installed independently. Installation always consists of several stages, none of which can be neglected. Let's consider how you can build different types of structures with your own hands.

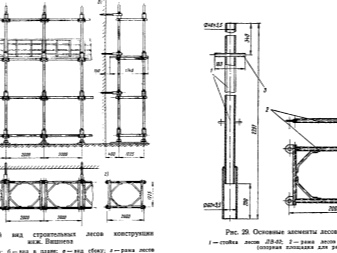

Shtyrevykh

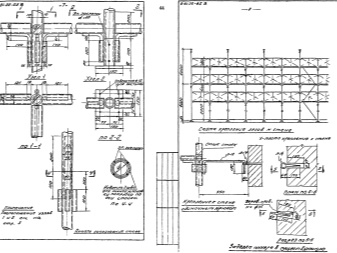

Often, pin scaffolds are installed for construction work. Let's take a step-by-step instruction on how to do it correctly.

- First of all, the master will need to prepare the site as carefully as possible, on which the structure will subsequently stand. The soil will need to be leveled and tamped well. After that, you can expose the support bases. They should be placed as close as possible to the facade of the building with which the builders will work.

- As soon as the supports are prepared and installed, it will be necessary to firmly fix the first 4 racks of the future structure on them. It is necessary to pay attention to the fact that the racks are of the same type and match in size.

- The next stage is the installation of the next pair of racks. Making strapping with crossbars, the master will need to go around the structure, moving along the perimeter. You will need to fasten the first and last pair of uprights together.

- After that, you will need to competently "build up" the resulting forests to a suitable height level. In the course of the work, the master will need to remember about fastening the new racks with the racks located in the lower tier. It will be necessary to combine them by means of crossbars. As soon as the structure reaches the desired height, you can start installing stairs and fences, laying the flooring. The fastening of the scaffolding to the wall must be reliable and strong.

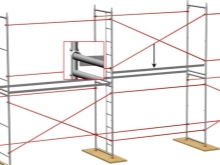

Ramnykh

Framed scaffolding can also be installed by yourself. In terms of assembly, such designs turn out to be the simplest. They are especially popular among builders, because they do not need special knowledge and expensive professional tools for their construction.

If the finishing of a small house is planned, then 2 people can easily cope with the installation of frame scaffolding.

If the structure is larger, then it will not be possible to put the scaffolding alone or even together - a team of 3-5 people will be needed.

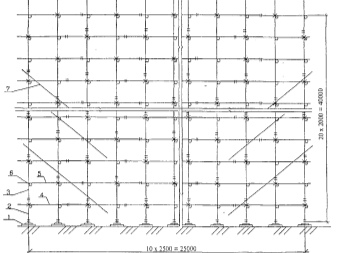

Frame scaffolding is mounted as follows.

- First comes the preparatory stage of work. It is at this moment that the masters need to familiarize themselves in detail with the technical passport of the structure, correctly prepare the selected site and conduct mandatory instructions for the workers.

- As soon as the area for scaffolding is ready, it is necessary to place on it special wooden pads 4 cm thick, as well as "shoes" (support heels).

- Next, 2 adjacent frames belonging to the first level are installed on the shoes. Between themselves, they must be fastened with diagonal and horizontal strips.

- The rest of the frames are mounted in the same way until the building acquires the required dimensions. It is very important to strengthen the structure on the wall of the building as conscientiously as possible so that it does not stagger.

- Next, you need to set the crossbars at the starting working level. Decking will need to be installed. It is important to fix the latter as firmly and reliably as possible for the proper level of security.

- The allowed indicator of the width of the slots between the detached boards should be no more than 0.5 cm. The floorings should be overlapped along the length. The joints must be placed precisely on the support bases. The side parts of the decks should not be less than 15 cm.

- Once the starting tier is completed, the frames for the next tier can be installed. They also need to be connected by diagonal and horizontal ties, which can be installed in a checkerboard pattern.

- The second tier will need to be fixed to the wall using anchor brackets.

- All other actions will need to be performed in the same way as described above, until the structure reaches the required height.

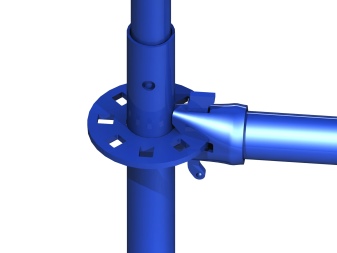

Wedge-clamp

There is another subspecies of scaffolding - wedge-clamp. These structures are assembled according to a certain plan. Let's consider what stages it consists of.

- As in the above two cases, first the workers will need to correctly and carefully prepare the site on which the installation work will be carried out.

- Next, jacks and pads are placed on the prepared base, the axes of the screws of which must be installed strictly vertically.

- The next step is to place the first ladder sections on the jacks placed on the site. It is best to connect them with farms. Next, you will need to qualitatively install the support legs.

- In order for the building base to be exposed clearly and evenly, various relief differences can be compensated by means of screw jacks.

- Next, the masters will need to correctly install the load-bearing trusses. They must be fixed at the height where the flooring is planned to be laid. After that, you can safely install the flooring.

- The safety elements are assembled at the same time with the flooring holders.

It is very important to know that the deck holder mentioned above, as well as parallel sectors of stairs, must be at the same level. This can be achieved if the trusses are correctly adjusted by moving them in a vertical plane.

Useful Tips

Let's take a look at some useful tips for installing scaffolding.

- When installing structures with a height of more than 5 m, it is required to fix the equipment elements on the surface of the building wall.

- The flooring can be made not only of wood. Metal parts will also work. Decks are often made from perforated steel sheets.

- If the scaffolding is planned to be assembled from wood and the different parts in them will be fastened with nails, it is recommended to make all the holes in advance. In this case, the boards will not crack.

- If you need a mobile structure, it can be made on wheels, not forgetting the safety rules.

- Homemade metal scaffolding after completion of work does not have to be disassembled - they can be rented out.

For how to quickly assemble scaffolding, see below.

The comment was sent successfully.