Types of scaffolding and their sizes

It often happens that the necessary repair or construction work must be carried out much higher than human height. Ladders and stepladders will not always save you. Then scaffolding comes to the rescue.

What is it and what are they made of?

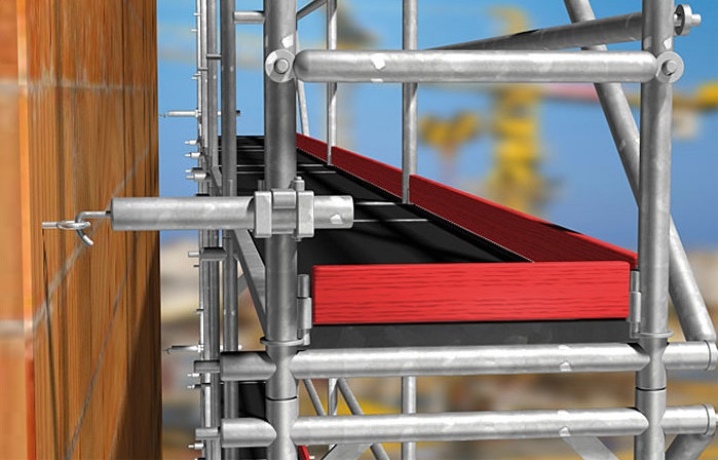

This structure looks like an interlacing of metal supports with stiffeners. The complete set of such a construction device includes flooring, as a rule, wooden. The scaffolding helps in the implementation of construction or repair work on tall buildings. They can accommodate not only builders, but also raise the necessary tool.

Primary requirements

The production of scaffolding is regulated by GOST 24258-88, and storage rules - by GOST 15150-69. The width of the wooden flooring must be at least 1.5 m. The width of the gap between the boards must be less than 1 cm. The material for the flooring must overlap on the support of the structure and protrude at least 20 cm on both sides of it.

Fences from 1 m in height are mandatory for decking boards or boards located at a height of 1.1 m or more. If the scaffolding in its height exceeds 6 meters, then at least two decks should be installed on such a structure: an upper working and a lower protective one.

When working from two decks at the same time, an intermediate one must be installed between them.

The kit also includes ladders that are installed between the tiers. The ends are fixed at the top. Scaffolding is usually grounded to protect workers from accidental electric shock. Suspended wires from power tools are fixed on special insulating elements. The quality of the installed scaffolding up to 4 m in height is assessed by the manufacturer.

How are forests made?

The basis for scaffolding is metal pipes, which are produced in a pipe rolling mill. After production, the finished material is sent to the warehouse of the manufacturing plant. Pipes are of various types (seamless, water, main, electric).

Electric welding (the most common option) pipes are made from pieces of sheet steel, which are pre-cut into strips of the desired size and subjected to the necessary processing. Then the resulting material is sent to the drive. There, pieces of sheet metal are stitched together by high-frequency electric welding. This is how blanks for future pipes are obtained. The processed semi-finished product is sent for calibration by a specialized machine, thanks to which all production surpluses are removed.

After all the actions, the pipes are tested with special equipment and visual control, and then they are sent to the blank section. There they are cut on a band machine in accordance with the required dimensions. After cutting, they are cleaned and drilled in accordance with the specified characteristics. Then the parts of the future frame are welded. This is the main manufacturing step, giving the pipes the desired shape of the prefabricated elements.

Description of species

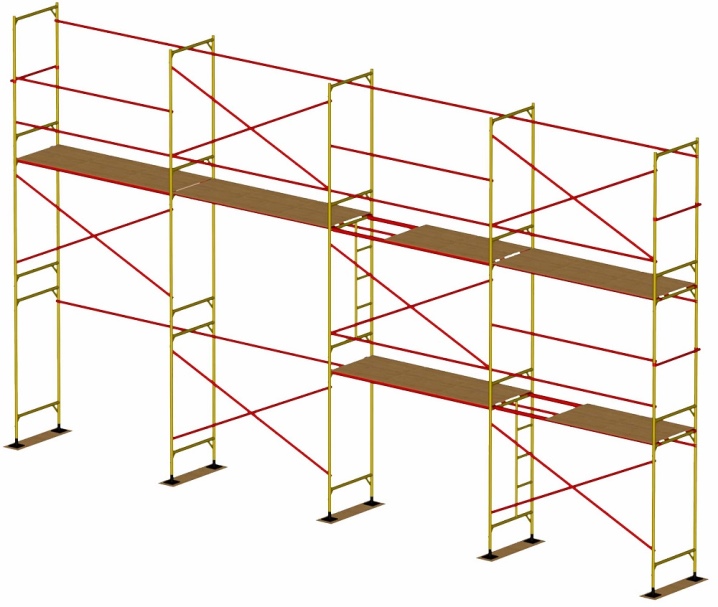

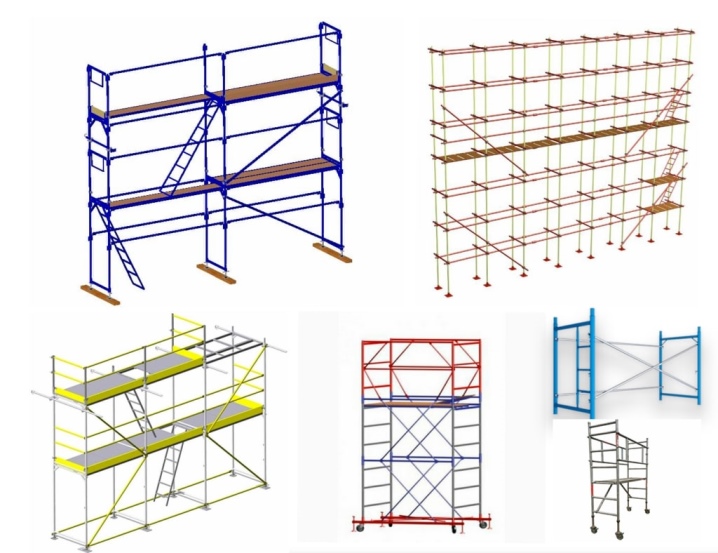

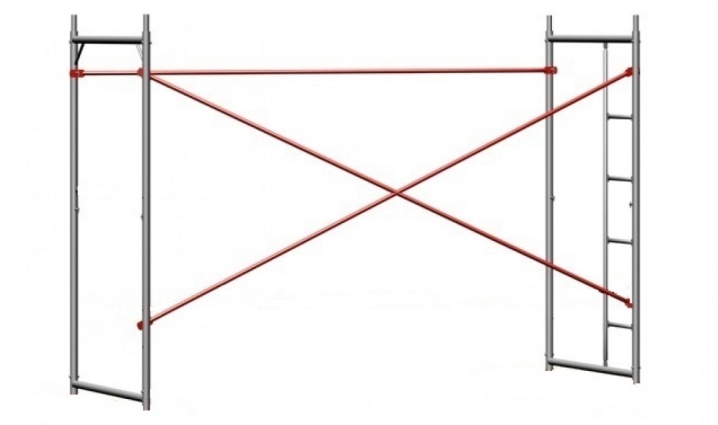

Framed

Such scaffolds are very common for construction and restoration work. The frame structure is extremely easy to assemble and build.The whole structure is made of metal frames, which are secured with fixing locks. Inside the resulting structure, flooring is left for horizontal movement and stairs with hatches for vertical movement.

Supports form the main basis of this design. The simplest legs are non-adjustable pipes on a welded heel. However, at the moment, more and more often you can find adjustable supports on wheels, which are equipped with towers. Such a device increases the mobility of the forests and their functional usefulness.

For the basis of the structure, pass-through tubular frames are used, and ladder frames are assembled to move the production staff between the sections. The number of sections and their structure is determined by the dimensions of the building or other structure, as well as the type of planned work. To increase the rigidity of each frame, additional pipes are used, which are fastened crosswise inside each section at the corners.

For the movement of workers, wooden boards or flooring made of pine or spruce are used. For moving loads and heavy tools, it is recommended to use perforated steel decks. At the same time, there is also a combined type. It is ordered depending on the tasks ahead.

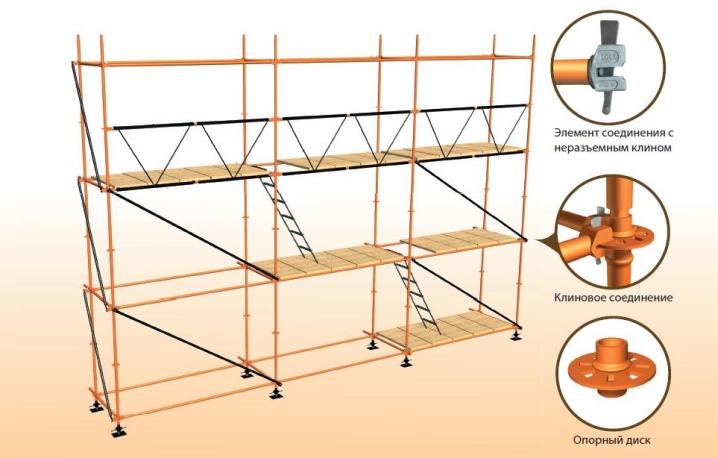

Wedge

Collapsible wedge scaffolding is a versatile and functional building structure, its use is possible in almost all types of work. These qualities are a consequence of the configuration features: it can be absolutely any and depends only on the form of the serviced building or other structure.

The wedge mount strengthens the installation and makes it much more reliable. The incomparable advantage of wedge-shaped scaffolds is their ease of assembly, which does not require much experience from the builders.

However, all the same, the preparation of the structure for work should be entrusted to specialists. This type of forest is used:

- for shipbuilding and repair;

- for work in oil and gas production;

- when carrying out masonry activities made of heavy stone materials;

- for the production of interior work;

- for the creation of non-standard structures (concert podiums and stages with stands).

This building device is considered the most suitable precisely for carrying out facade restoration work. This is due to the lightness of the basic design. This quality will ensure the maximum preservation of the facade of a building or other structure.

Pin

This term is called a temporary building structure, in which the constituent elements are fastened to each other by using hinged joints. This method of fastening, as well as the use of strong tubular elements with thickened walls instead of conventional steel pipes, ensure maximum safety of the work carried out and increase the possible load. Thus, one square meter at a height of 80 m of such a temporary pin structure can withstand a weight of up to half a ton. This variety is used for:

- implementation of masonry activities from heavy stone materials;

- carrying out front finishing and repair works.

This structure, due to its design, has increased strength and reliability characteristics, which ensures the safety of production personnel. Also, pin scaffolds are very durable and not subject to rapid wear. Mounting / dismantling of pin scaffolds is carried out quickly enough, which makes it possible to transfer the entire structure to a new place without any special obstacles, if necessary. The elements of the pin product are also stored rather compactly.

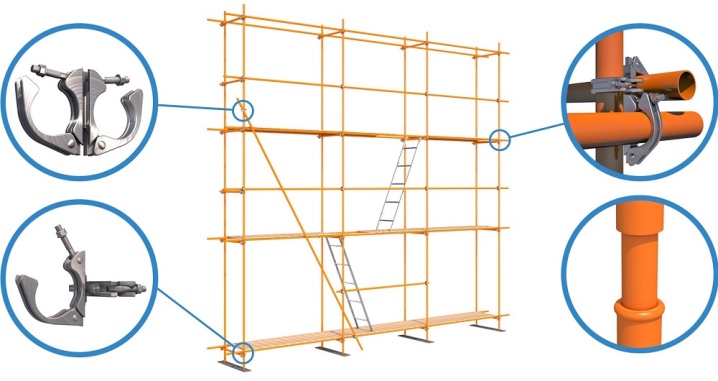

Clamp

Scaffolding of this type is assembled from supporting elements, the connection of which is carried out through special clamp fasteners. This design has a high level of strength and safety, which increases its functionality. Clamp scaffolding is used for:

- the production of masonry tasks, if they can be performed at a height of no more than 20 meters;

- the production of finishing and restoration work, if the height of the serviced building does not exceed 80 meters;

- the implementation of facade work on a slope or buildings with a non-standard configuration;

- the construction of various non-standard structures, for example, stages, stands or shelving.

Clamp prefabricated structures can be combined with various types of attached building structures. However, it should be remembered that, due to their purpose and assembly technology, they are not mobile.

To assemble the racks together in these structures, crossbars are used, which are installed across the structure and attached to the walls of the building.

The main method of vertical movement in the scaffolding for workers is ladders, one end of which is hung on the crossbar with the help of built-in hooks. The entire frame of the clamping scaffolding is mounted to the walls of the structure with anchor bolts.

Suspended

This type includes the subspecies "strings" and is used when, for one reason or another, it is impossible to use the zero point as a support (ground, stone cover, etc.). In this regard, traditional types of forests cannot be erected either. This can happen when:

- facade extensions and architectural elements are weak;

- technical means do not have access to the object;

- bridge structures are being repaired;

- construction and repair work is carried out at an altitude of more than 100 m;

- glazing of facades is carried out simultaneously with construction and repair work;

- industrial pipes on the upper levels are subject to reconstruction and diagnostics.

The structure of the suspended scaffolding is based on lightweight frame and post elements. Clamp / string ties are usually used to connect all the constituent components. To use such a structure, it is necessary to hang it to the facade of the object using the brackets intended for this. Despite the seeming simplicity of installation, before each installation of suspended scaffolding, a detailed installation project is drawn up, which prescribes the chosen method of future fastening of the structure to the surface of the building.

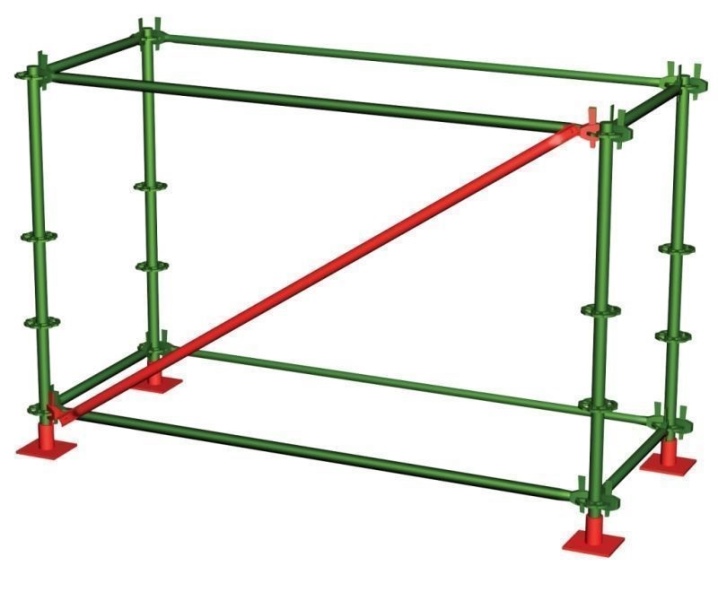

Cup

Such rack-mounted scaffolding is used for construction, repair and restoration work directly in the place of their need. This design uses a cup-type attachment of modular elements. This solution eliminates the need for diagonal stiffeners.

This type of scaffolding has a minimum number of assembled parts:

- vertical racks equipped with a cup mount;

- horizontal ribs - crossbars;

- adjustable support elements;

- ladders for communication between tiers and working platforms for horizontal movement along the building structure.

This type of forest has the following clear advantages:

- high indicators of reliability and safety of operation;

- good structural rigidity and the resulting increased maximum load on the structure to its irreversible deformation;

- the ability to create sufficiently long spans without sacrificing reliability (up to 3 meters);

- high impact resistance characteristics;

- fast assembly;

- flexibility in terms of the ability to create various forms;

- unusual connecting system;

- lack of fasteners and unnecessary accessories, which are very much lost during disassembly and transportation.

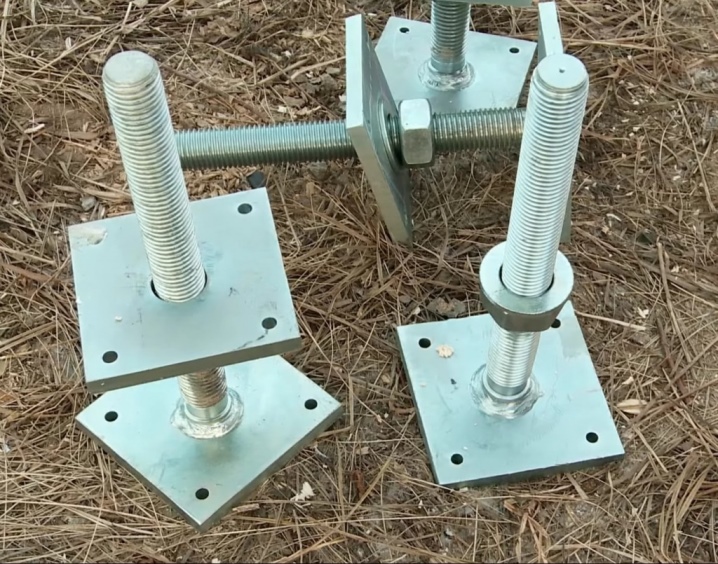

Mechanical scaffolding jacks

It often happens that forests need to be placed on uneven terrain, which is not possible to fix. Then they use mechanical scaffolding equipped with construction jacks. These are stabilizing devices that allow you to align the entire structure with respect to the zero point of support. Alignment is carried out by rotating the nuts on the screw posts, which are equipped with backings.Jacks do not need expensive and painstaking maintenance. Periodic lubrication and checking the integrity of the device will be enough for them.

Dimensions and weight

The dimensions and weight of these structures vary depending on their type and purpose. Wedge mobile structures can reach dimensions up to 100 meters in height and take on loads weighing up to 500 kg per square meter. Pin scaffolding has a total of three model varieties, each of which has its own characteristics:

- the LSh-50 model reaches a height of 50 meters;

- ЛСПШ02000-4: the height of 40 meters is the maximum for this structure;

- E-507 can be assembled up to 60 meters in height.

Clamp scaffolds, due to their strong rigid structure, can reach a height of 80 meters, however, the peculiarities of their assembly do not allow them to be less than 30 meters. Such scaffolding can have any desired shape, if necessary, they can even be made triangular.

There are also homemade scaffoldings that are harvested for home renovation and cladding by their owners. The height of such a "self-made" installation can reach 6 meters. The smallest representative are the so-called mini-forests. In fact, this is an ordinary construction goat, which reaches a height of 1 meter and is used in work at a height slightly higher than human height.

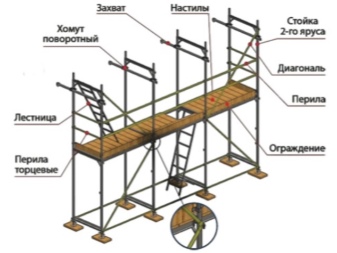

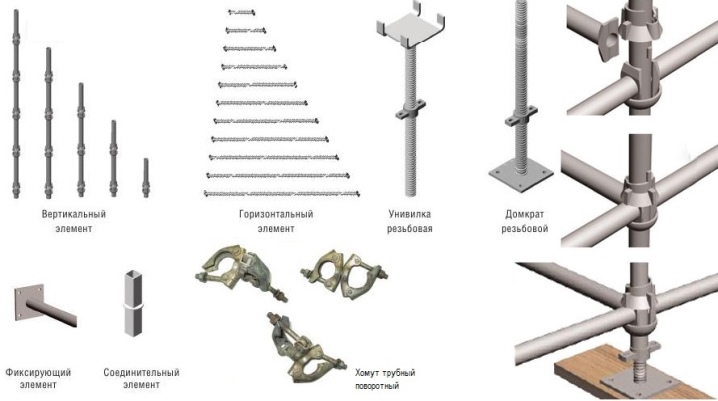

Components

- Frames. They are the main supporting element of scaffolding made from pipes of various diameters and materials (metal, bamboo, wood). They are connected to each other using the pipe-to-pipe method in the vertical plane, and for horizontal fixation, diagonal and horizontal ties are used. There are ladder frames and walk-throughs.

- Diagonal tie. It consists of two pipes connected together in a cruciform manner. All four ends are attached to the corners of the frame, making it stiff and less prone to deformation. Installed from the outside of the scaffolding. Used across a section, but in some cases can be used to tie each outer frame.

- Horizontal link. It is an element made of a pipe with a diameter of 25 mm for fastening to the frame. Used to tie up frames and support barriers for production personnel. Fastened to the outside of the scaffolding.

- Support. The supporting element of the entire building structure serves as a supporting base for it. The standard version is a pipe with a metal heel welded to it. The more advanced versions are adjustable and equipped with screw elements to adjust the height. The number of supports included in the kit varies (it depends on the customer's requirements and the characteristics of the landscape).

- Rigel. This element is intended for laying the flooring. It is a pipe equipped with special hooks and attached to frames along the facade so that workers can move freely in a horizontal plane.

- Flooring. It is a wooden pallet or steel shield for horizontal movement of workers, as well as for moving loads, tools, equipment.

- Anchor. Fastening element, mounted on screws between the facade of the building and the scaffold frame. It is made in the form of a pipe and a clamp (tubular) or from a steel strip with a clamp (strip).

Nuances of choice

- The most affordable choice for a cottage or for a summer residence will be frame scaffolding. Moreover, this design can be used not only for outdoor, but also for indoor work.

- If it is necessary to perform masonry work at a high altitude, it is worth purchasing wedge scaffolding - they differ in maximum load per 1 sq. meter up to 500 kilograms with a maximum possible height of up to 100 meters.

- On yoke scaffolding, it is possible to carry out masonry walls up to 20 meters high or to organize facade works at a height of up to 60 meters.

- The pin design will help organize repair and finishing work on buildings with a non-standard configuration. Such scaffolds are durable and reliable, and also have a high bearing capacity.

- Construction gantries are ideal when all work is carried out on the ground floor level. They are extremely mobile and easy to use, and do not require complex expensive maintenance or permanent assembly / disassembly.

In this video, you will learn how to make scaffolding from boards with your own hands.

The comment was sent successfully.