Description of wedge scaffolds and their installation

Wedge scaffolding is a rigid structure made of metal profiles, which is used for repair or reconstruction work. The versatile and convenient structure is excellent for the installation of various structures or for finishing and restoration. Today, wedge scaffolding is considered the most popular due to its increased safety and low price.

Features and design elements

Construction and installation or repair work requires the use of scaffolding. With their help, it is possible to organize:

- roof filing;

- building insulation;

- decoration of walls and facades;

- construction of suburban facilities.

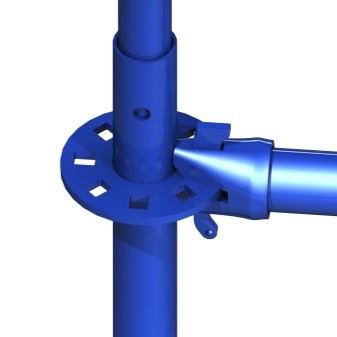

The scaffolding, made of steel pipes and decking, is capable of withstanding loads of up to 500 kg. The key feature of such structures is that the support formwork can be assembled by connecting horizontal and vertical components. The elements are fastened to each other by using a locking mechanism that prevents unexpected separation of parts.

To assemble the scaffolding, installers do not have to make significant efforts, and the operation of the structures does not require additional investments. The second feature of wedge scaffolds is that they are safe for any type of construction work.

The advantages of wedge-type designs include a number of factors.

- High structural reliability... The connection of the elements of the wedge scaffolds is carried out using locking mechanisms, which makes it possible for the installation of bulky goods.

- Versatility... Scaffolding is erected for the construction and decoration of various objects, regardless of the complexity of the work carried out and the configuration of the structure.

- Ease of assembly and disassembly of the structure. The key tool is a hammer for driving and removing the wedge from flange locks.

The full use of wedge scaffolds is possible only after careful installation. In this case, the engineer and technical specialist must check the readiness of the structure and write out a permit for the operation of the structure.

For the device of wedge scaffolding, the following elements are used:

- vertical metal racks;

- crossbar for fastening horizontal racks;

- horizontal racks;

- shoes that act as a supporting part;

- starting part, which is a vertical with flanges;

- diagonal for connecting elements and ensuring the strength of the structure;

- jack, made in the form of a thrust bearing;

- ladder made of metal profiles;

- flooring made of wood or sheet metal;

- brackets and other fasteners.

And also the structure includes a stabilizing support and a hinged console.

Dimensions (edit)

Wedge scaffolding is in demand on many construction sites where the organization of facade work is required. Such structures have two standard sizes that determine the working height of the structure.

- LSK-60. In this case, the maximum height of the scaffolding will be 60 m. The structures are constructed from pipes with a diameter of 48 mm and a wall thickness of 2 mm.

- LSK-100. Structures 100 m high are assembled from pipes with a diameter of 48 mm with a wall thickness of 3 mm.

And also wedge-type forests are capable of forming sections with a height of 2 m each. The width of the passage between the sections does not exceed 1-3 m.

Mounting

Before proceeding with the installation of the structure, it is worth checking the availability of the necessary tools, as well as preparing the required equipment. The specialist who will install the structure will need to carefully study the PPR scheme and check the parts to detect damaged elements.

Installation of wedge scaffolds is carried out taking into account the requirements of building codes, which include SNiP 12-03-2001 and various GOSTs... And also it is necessary to take into account the safety requirements: perform work in protective clothing and using reliable tools.

Installation is carried out in a specific sequence.

- First, prepare the site... It must be cleaned of construction debris, snow, dirt, and also tamped until a flat surface is obtained. Additionally, you will need to dig ditches to drain the water.

- The second stage involves the installation of scaffolding from the corners of the building. At the same time, it is important that the access roads to the object are organized correctly, and the structure does not interfere with the passage of construction equipment.

- Further, under the shoes of the scaffolding, wood lining is installed, the thickness of which does not exceed 45 mm in the transverse direction. Sometimes, instead of shoes, jacks are installed, which manage to align the structure with the horizon.

- The fourth stage is installation of starting elements, which are fastened by means of longitudinal and transverse ties.

- When the previous work is completed, the master will be able to proceed to the main stage, which implies installation of vertical pillars in starting elements... The racks are fastened using locking mechanisms or flanges. It is important in the process to track the level using a special tool or plumb lines.

- To ensure the safety of the uprights, the structure is reinforced with brackets, attaching it to the wall of the object... Additionally, hinged consoles are installed.

- Then, on each tier of the scaffolding, floorings of wood or metal sheets are laid. They also erect sides, install a ladder for organizing the ascent and descent.

- The next step is to strengthen the structure by installing a diagonal, which is attached from the end in two adjacent spans. In this case, the distance should not exceed 9-12 m.

- Next, the master installs a railing that can withstand a load of 70 kg. It is especially important to install the handrail on the upper tiers to prevent the risk of installers or plasterers falling over.

Finally, at the last stage, the structure is grounded to avoid the effects of electrical charges during a thunderstorm. After the construction work is completed, the same craftsmen dismantle the structure, adhering to the reverse order. First, they remove the diagonal, railings, flooring, then dismantle the stairs and get rid of debris.

In the process of dismantling, the craftsmen sort the parts with their subsequent packaging.

Transport and storage

The disadvantage of wedge scaffolds is that they are not completely covered with paint. Unpainted elements require special conditions for reliable transportation and high-quality storage. Before these measures, it is required to preserve the components with grease or other lubricant. Transportation of equipment is carried out on a special transport capable of accommodating all the components of the set.

Wedge scaffolding - versatile and safe construction, which is suitable for finishing, repair and restoration work, as well as for the construction of various buildings and structures.

For a description of wedge scaffolds and their installation, see the video below.

The comment was sent successfully.