Washing machine drum repair

Household appliances can bring increased comfort to life. Nowadays, few people do without the convenience of a washing machine. This device very quickly changed from a luxury item to an indispensable element of a comfortable life. Therefore, when the machine breaks down, many people have a panic. However, even without a wizard, you can quickly correct the situation by familiarizing yourself with the structure of the washing unit.

Causes of breakdowns

The malfunction of the washing device can be determined by many signs.

It is worth paying attention to the machine if the drum has a strong backlash in the spin mode. This process can be accompanied by significant rumble.

Often, the drum can make sounds when it hits the hull or hatch.

Excessive jumping and vibration of the washing machine also indicate a malfunction. Another sign is a frequently flying drive belt. Also, the drum often rubs against the collar on the loading door. In this case, the operation of the unit can be carried out normally, and only various noises or squeaks will be heard.

Watch out if traces of oil are visible under the washing machine. Leaks or traces of rust on the tank also indicate problems. It is important to pay attention in time to the strong chattering of the drum, its distortion, wedging, difficulty in scrolling, metal grinding. Chewed linen, constantly escaping corks, smoke from the unit should also alert you.

All of the above symptoms indicate that a significant breakdown has occurred. Moreover, even if all modes are performed in full, it is not worth using the unit. This can cause serious malfunctions that cannot be repaired.

Often times, the drum stops working properly due to faulty bearings. This is primarily seen in the underbody leakage, strong hum and excessive vibration. In this case, it is necessary to change not only the bearings, but also the oil seals. This failure is preceded by water entering the bearing and causing corrosion. As a result, the service life of the part is significantly reduced.

When significant drum hits are heard during washing or spinning, then one must look for the cause in worn shock absorbers. You can check this on an open car. To do this, pull the drum towards you and then release it. When rocking it, if it does not immediately snap into place, repairs should be started immediately.

Sometimes foreign objects can get into the tank, including socks, nuts, coins. This makes the tank difficult to spin and makes unpleasant sounds. Sometimes particles of destroyed bearings or shock-absorbing elements are found directly in the tank itself. At the same time, it is felt that the drum is loose, wobbly, and you can hear a loud grinding.

How to check the backlash?

In washing units, a small percentage of backlash is laid down even during manufacture. but while there is no extraneous noise.

If, during the operation of the machine, strange and loud sounds are heard, then you should look for a malfunction.

For this you need to open the hatch door in the washing unit and take the drum with your hands... After that, it must be moved in different directions without undue effort. Then you should twist the drum clockwise, and then counterclockwise. If at the same time there is a rattle, then you need to look for the problem.Also, at high revs, you can hear the drum beating, jumping and swaying, accompanied by loud sounds.

You can understand that there is a breakdown when the machine is turned on and operates in the spin mode at high speeds. During fast rotation, you can hear that the drum is dangling and extraneous noises are heard. It may even appear that the tank has come off.

At the initial stage, without disassembling the device, nothing else can be determined. However, having penetrated under the case, you can further identify what the malfunction is. For example, you should inspect the springs and shock absorbers, shaking them a little.

In the event that failed springs or faults in damping are identified, then it is enough to replace the broken parts without even disassembling the tank.

Otherwise, it is necessary to carry out a complete disassembly.

Another cause of backlash can be counterweight problems. This weighty unit is included in every washing device. Its main purpose is vibration damping. However, the mount may not always hold it due to wear and tear. As a result, the block ceases to perform its functions, the tank staggers and the sound is heard from their impacts against each other.

Of course, such malfunctions are quite rare, and they cannot be repaired without the help of a specialist. It is very difficult to adjust the bolts or replace a heavy part on your own.

How to replace a bearing?

You can install a new bearing instead of a faulty one yourself. but you should read the instructions in advance in order to properly prepare the device for replacement. It's worth starting with the preparation of all the necessary tools, as well as new parts, including oil seals.

After that it is necessary to disconnect the washing unit from the electrical network. Then the device should be installed so that the rear panel is accessible. On it, you need to unscrew all the fasteners, and then remove the entire panel. Then you can remove the detergent dispenser. Using a screwdriver, unscrew the electronic control unit and set it aside.

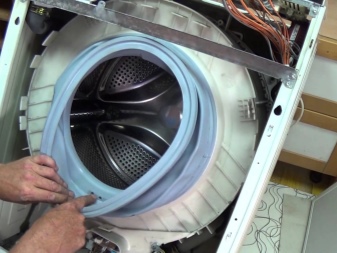

After detaching the lock, you can get the rest of the parts and then remove the front of the panel. To loosen the clamp, remove all interfering elements. Then you can dismantle the counterweight and heating element. However, it is important to remember how the main nodes are located. You can even take pictures of them for this.

Replacing the bearing begins with unscrewing and removing the pulley. After that, the shaft is knocked out with a rubber hammer. Next, you need to unscrew the bolts that connect the parts of the tank. Now that the bearing is visible, it needs to be knocked out. For this, a chisel is used.

At the last stage, the oil seals are removed. After that, a place is being prepared for a new part. First, it is cleaned, and then lubricated with a special agent. Now you can collect everything, but only in the reverse order.

Replacing the shock absorber

If the breakdown lies in the shock absorber, then it is important to immediately stop using the washing device. Prolonged use of a defective unit can lead to unpleasant consequences. It should be noted that the shock absorbers can only be changed in pairs. Carrying out this procedure with your own hands is completely easy if you adhere to a clear plan.

In many new models of washing equipment, the shock absorber is attached from the bottom. This makes the part easier to access and replace. However, this only applies to brands such as Beko, LG, Ardo. Most often, the repair of a washing machine drum due to worn shock absorbers does not take place without a complete disassembly of the front panel.

This process must be started by loosening the bolts, and then removing the upper part of the unit. The next step is to get the detergent drawer. After that remove the control unit and completely disconnect the wires. Now you need to remove the clamp and the rubber cuff.

For to remove the front part of the panel, you must unscrew all the bolts. After that, it is important to remember in what order the parts are located. It is best to take preliminary photos to avoid confusion.

The springs must be removed one at a time, first loosening. After that, it is important to inspect the attachment points for integrity. Once the tank has been emptied, new shock absorbers can be attached and the tank replaced. At the end of the assembly, check the operation of the washing device.

How to get a foreign object?

In the event that small foreign objects interfere with the proper operation of the drum, then you should not worry too much. They can come out on their own through the drain pipe. These elements are then easily removed from the filter. To do this, the latter is removed from the washing device and cleaned of all foreign matter. Before this procedure, it is advisable to spread rags, since water will pour out of the filter hole.

At times, foreign elements fall to the bottom of the tank, from where it is much more difficult to get them. In this case, their extraction is carried out through the opening of the heating element. It should be noted that depending on the model, the heating element can be located at the back or front of the device. Based on this, certain fasteners are removed, and then the heating element itself is removed. After that, you can extract everything unnecessary.

How to replace bearings in a washing machine, see the video.

The comment was sent successfully.