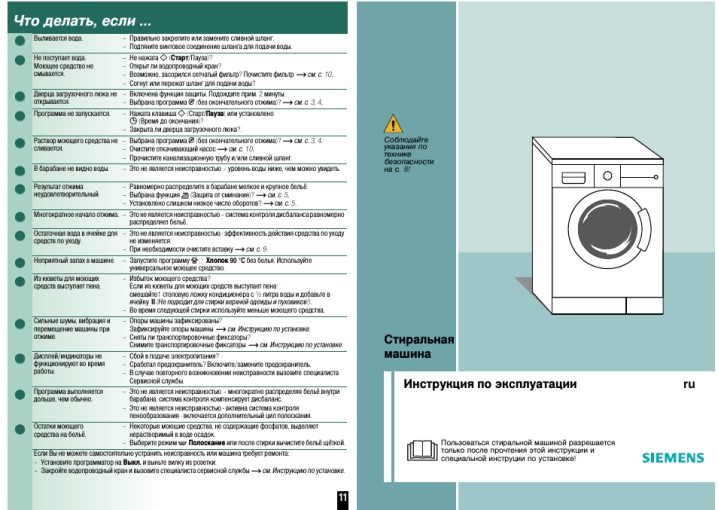

Washing machine malfunctions

A washing machine is an essential household appliance. How much it makes life easier for the hostess becomes obvious only after she breaks down and you have to wash mountains of linen with your hands. Let us dwell in more detail on the causes of device breakdown and how to diagnose faults.

Diagnostics

Most modern washing machines contain a built-in self-diagnosis system, which, when a malfunction occurs, immediately makes itself felt by stopping work and displaying an error code message. Unfortunately, it is impossible to know all the numerical-alphabetic indicators of the malfunction used, since the coding differs from manufacturers.

As a rule, the main list of breakdowns is indicated in the user manual, and in the event of a problem, each owner can easily determine which of the unit's elements failed.

Machines with partially mechanical control do not provide for such coding, therefore, you can identify the source of problems in them by following simple tips.

- If the structure is turned on, but no washing mode is started, then the cause of such an unpleasant phenomenon may be a malfunction of the socket, a break in the power cord, a breakdown of the power button, a malfunction of the hatch cover lock, a loosely closed door.

- If after starting you do not hear typical engine running sounds, then the reason lies in the absence of a signal from the control unit. This usually happens when the motor brushes break or wear out, or a winding breakdown occurs. In addition, a similar problem occurs with an internal motor malfunction.

- If the engine hums, but the drum is not spinning, then it is jammed. It is possible that the thrust bearings are broken.

- Lack of reverse indicates a malfunction of the control module.

- If liquid enters the drum very slowly, the coarse filter may be clogged. In the absence of water entering the drum, you need to look at the valve: most likely, it is broken. If, on the contrary, water is poured in an excessive volume, then this indicates a breakdown of the level sensor. When fluid flows out, in the vast majority of cases, there is a breakdown of the drainage hoses or cuffs.

- With strong vibration during washing, the springs or shock absorber often break. Less commonly, a failure of the support bearing leads to such an error.

If you cannot determine the cause of the breakdown of the machine yourself, it is better to use the services of professional craftsmen. They have knowledge of the features of machines of all manufacturers, and also have the equipment necessary for diagnostics.

Major malfunctions and their causes

Washing machine malfunction is a common occurrence, since this technique is usually used in an intensive mode and, like any other mechanical device, has its weak points. The causes of breakdowns are usually errors in the use of technology, wear of the main parts and assemblies, erroneous manufacturing decisions or factory defects.

Let us dwell in more detail on the common malfunctions of modern washing devices.

Does not turn on

If the machine does not turn on, then this will manifest itself in different ways: the unit may not react at all to user commands, or it may turn on light sensors, but do not start the washing mode.

The most common cause of the problem is power outages. Immediately you need to make sure that the outlet is working. It is not difficult to do this: you just need to connect a known working device to it. After that, you need to carefully inspect the plug: it is possible that there is a break in the area of its connection with the cord or there is other damage. It also happens that the plug is simply not tightly connected to the connector.

If you have performed all these manipulations, but have not found the source of the malfunction, you can proceed to further diagnostics. Sometimes it turns out that the washing machine is in perfect working order, but the mechanism for turning it on was incorrect. Most modern products have child protection function, which aims to prevent accidental activation of technology. If this program is activated, then the rest of the buttons simply do not respond to user commands. Most often, to disable protection, you need to dial a combination of several buttons, then the mode indicator lights up on the display.

Many devices will not turn on if if the hatch door lock is not latched. As a rule, the indicators flash, but the wash does not start. The reasons may be underwear caught under the lock or a technical malfunction - deformation of the bolt hook.

If the washing machine does not start for no apparent reason, then the control unit is most likely out of order. Then you need to assess the state of the electronic board, check if the microcircuit is flooded with water, make sure that the network capacitor is working properly.

The drum is not spinning

If the drum of the washing unit does not rotate, then it is most likely jammed. It is very simple to check it, you just need to move it from the inside with your hands. If it is really jammed, then it will stand or stagger slightly, but not rotate. In this case, remove the case and use a flashlight to look for the stuck object. In many machines, bones from women's underwear, small buttons and coins fall into this space. The drum can also jam from a worn bearing. It is quite possible to establish such a breakdown visually.

If the program is running, the engine is running, but the drum does not move, then most likely the transmission belt fell off. Some products allow you to tighten it, but if such an option is not provided, the belt will have to be replaced with a new one. Keep in mind that when buying this part, you must definitely choose a model that is completely identical to the first one in terms of geometric parameters.

In direct drive technology, the drum is directly connected to the motor. The transmitting link in this case is absent, and this greatly increases the reliability of the structure. However, if a problem occurs with such a unit, then any leaks from the tank immediately enter the motor and lead to a short circuit.

In this case, repairs will have to be done in a specialized workshop, and for a lot of money.

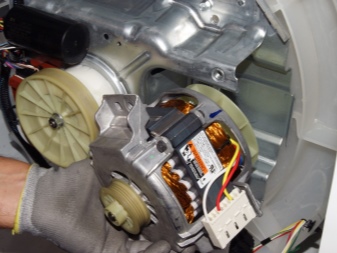

If the drum does not rotate in a modern car and there is no sound of a running engine, then you will need replacement of engine carbon brushes: for this, the motor will have to be completely disassembled, the brushes that have served their life should be pulled out, and new ones should be put on them.

Pay special attention cleaning the collector lamellas, as they provide good contact. Often the cause of the malfunction is a cable break or pinching, a little less often there is a gap between the control unit and the engine itself. At the same time, the command to start work simply does not reach the drum.

The water does not heat up

Hardly anyone will argue with the statement that the machine does not wash well in cold water. Therefore, if the machine is running, rotates the drum, washes and rinses, but the water does not heat up, this should be a reason for an immediate diagnosis.In almost 100% of cases, a similar problem occurs due to a breakdown of the heating element. There may be several reasons for this:

- the appearance of scale on the heating element body due to too hard water (on the one hand, this significantly reduces the thermal conductivity, on the other hand, it causes the destruction of metal elements);

- physical wear of the part: usually the user manual prescribes the maximum service life of the equipment, taking into account natural depreciation;

- frequent voltage drops in the network.

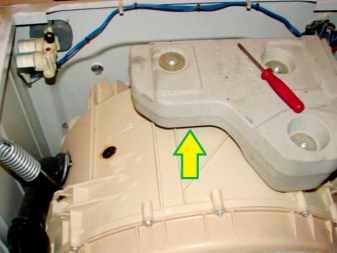

To get to the heating element, you need to remove the rear cover of the unit, disconnect all cables and sensors, and then remove the heater. Sometimes you can visually determine that the item is already faulty. If there are no external signs of damage, it is better to diagnose with a special tester.

If the heating element is serviceable, and the water still does not heat up, then you can consider other options for the malfunction:

- breakdown of the temperature sensor (usually it is located at the end of the heater);

- malfunction of the control module, lack of connection with it due to a broken wiring.

The door won't open

Sometimes a situation arises when the machine has finished washing and spinning, but the door has not been unlocked. Only a master can help here, but it takes a long time to wait for him, so the hostesses are forced to constantly run the wash in a circle so that the laundry does not fade.

Such a malfunction can happen for two reasons:

- the machine does not drain the water completely or the pressure switch “thinks” that the liquid is still in the drum and does not open the door;

- there is a breakdown of the UBL.

Spin does not work

If the machine has stopped draining the waste water, then with a high degree of probability the cause of the breakdown lies in drain system malfunctions or its individual elements: a hose, a valve, as well as a filter or pump.

First you need to drain all the water from the machine, turn it off for a quarter of an hour and try to start a second wash. This is usually enough. If the measure did not turn out to be effective, then you can use the gravitational force and install the unit higher, and the hose, on the contrary, lower. Then the water is drained off.

To prevent the occurrence of such a malfunction, you must wash the outlet filter regularly. During operation, small objects, fluff and dust are hammered into it. Over time, a slimy mud forms on the walls, as a result of which the outlet narrows, which greatly complicates the drainage. If the drain filter does not function, it must be carefully pulled out, rinsed under a strong stream of water and placed in a citric acid solution for 10-15 minutes.

If the unit does not start spinning, then the reasons may be more commonplace: for example, too many things are put in it or they are too large. When the laundry is unevenly distributed in the drum, the machine starts to vibrate at the moment of spinning. This causes the safety mechanism to turn on, so the wash stops. To correct this problem, you need to redistribute the laundry or remove half of the drum contents.

Imbalance can also be caused by damage to the spider or bearing. Also, spinning is often absent if the drum does not rotate at the unit. We have described above how to determine the cause of this malfunction.

Strong vibration and noise

The source of increased noise can be vibration, which is noticeable to the naked eye. It so happens that the car seems to bounce around the bathroom. In this case, make sure that all transit screws are removed.

When placing the machine, it must be set strictly in level, while it is recommended to use silicone pads under the legs. But the widely advertised anti-vibration mats, as evidenced by the reviews of the owners, are becoming an absolutely ineffective purchase.

Bad smell

When an unpleasant rotten smell comes from the car, it needs to be cleaned, and it is better to carry out a general cleaning. To begin with, you should run a dry wash with citric acid or a special anti-scale composition, and then thoroughly flush the drain system using antiseptic agents. It must be remembered that even with good care, the machine (if it rarely works in high-temperature modes) can become silted over time, especially the place under the sealing gum suffers.

The cause of the unpleasant smell may also be an incorrect attachment of the drain hose. If it is located below the level of the drum (at a height of 30-40 cm from the floor), then the smell from the sewer will get inside the unit. If this is the problem, you just need to fix the hose higher. After processing, the machine itself must be dried and ventilated. This is usually enough to make the smell go away.

Other

In addition to the above problems, modern technology most often encounters a door lock breakage. In this case, the machine turns off and the door does not open. You can fix this problem with a fishing line. To do this, insert it into the bottom of the hatch and try to lift it up so as to pull up the hook of the lock. If these actions do not help, then you will have to remove the lock manually. It is necessary to remove the top cover of the unit, reach the hook from the back side and open it. If you see that the hook is deformed or worn out, it is imperative to replace it, otherwise the problem will reoccur.

In some cases, the machine may not pick up the rinse aid at the end of the wash, and may not switch modes. Only a specialist should solve such problems.

Breakdowns of machines from different manufacturers

The overwhelming majority of manufacturers, when creating their washing machines, introduce the latest ideas. All this leads to the fact that units of different brands have their own specifics of operation, as well as malfunctions inherent only to them.

Indesit

This is one of those brands that do not cover their heating elements with a protective layer. It uses medium grade stainless steel, and this makes the unit more affordable in terms of cost. But under the conditions of using hard water, such an element with a probability of 85-90% becomes overgrown with scale and fails after 3-5 years.

This brand is characterized by software failures: the specified modes are not fully executed, they work in an incorrect sequence, and some buttons become completely inoperative. This directly indicates a breakdown of the control system and the need to reflash it. The cost of such repairs is so high that it is often more profitable to purchase a new structure.

Another problem with these machines is the bearings. It can be very time consuming to repair them yourself, since such work requires disassembling the entire drum structure.

Lg

The most popular units of this brand are direct drive models. In them, the drum is fixed directly, and not through a belt drive. On the one hand, this makes the technique more reliable, as it minimizes the risk of wear and tear on moving parts. But the downside is that such a design will inevitably lead to frequent equipment breakdowns: the drain path of such machines is clogged much more often. As a result, the drain does not turn on, and the machine shows an error.

Equipment of this brand often encounters breakdowns of the valve and water intake sensors. The reason is weak sealing rubber and freezing of the sensor. All this leads to an overflow of the tank, when, with constant self-draining, the machine is forced to collect water without stopping.

Bosch

Models from this manufacturer are considered the highest quality in the middle price segment. The manufacturer has made a special emphasis on the ergonomics of the equipment and its stability. The frequency of breakdowns is not very high here, but mistakes do happen. The weak point is the heating element controller, the breakdown of which does not allow the water to heat up. Besides, users are often faced with a loose belt drive.

However, all these faults are easily neutralized at home.

Ariston

These are economy class cars with a high level of reliability. Malfunctions mainly arise due to incorrect operation: for example, too hard water and insufficient maintenance of equipment. However, there are also typical problems. The overwhelming majority of users note the appearance of an unpleasant odor from the gum, loud noise and vibration during work. All this leads to rapid wear of the moving parts. Unfortunately, most of the elements of the unit cannot be disassembled at home, and their malfunction requires the intervention of a master.

Electrolux

The electrician of these machines is "lame": in particular, the power button often fails or the network cable is deformed. Usually, to diagnose a breakdown, such machines are called with a special tester.

Some users have noted software glitches that happen with machines of this brand. For example, the technician can skip entire rinsing and spinning steps. This indicates incorrect operation of the control unit, which entails the need to reprogram it.

Samsung

Washing machines of this brand are characterized by high build quality and reliable electronics. The risk of malfunctions of such equipment is negligible, so machine owners do not often turn to service centers. In most cases, malfunctions are associated with the failure of the heating element: such a breakdown occurs in at least half of the cases. A malfunction of this type can be easily eliminated at home.

Of the typical disadvantages of machines, one can also single out too light counterweight and, as a result, the appearance of strong vibration. Under these conditions, the belt may stretch or even break. Of course, the elimination of such breakdowns can be mastered at home, but in this case you will need an original part.

The outlet filter is located very inconveniently (behind the rear panel of the case), and it can be difficult to open it. That is why users are very reluctant to clean it. As a consequence, the system quickly generates an error.

For the main malfunctions of washing machines, see below.

The comment was sent successfully.