Why did the F12 error appear on the Hotpoint-Ariston washing machine and how to fix it?

The instructions of modern washing machines often contain insufficiently detailed descriptions of the meaning of the error messages issued by the device. At the same time, not all errors require expensive repairs, some of them can be easily corrected on your own. Therefore, it is worth finding out why the F12 error may appear on the Hotpoint-Ariston washing machine and how to eliminate the causes of its occurrence.

What does the error mean?

According to the technical descriptions of Hotpoint-Ariston washing machines, the F12 error appears in cases when the electronic module of the control system cannot communicate with the module of indicators located on the control panel.

Unlike many other errors that are issued on the initiative of the control system, the F12 error is generated by controllers located directly on the control panel.

All models with a display will report this error by displaying a code on the screen. Earlier models have different ways of reporting communication problems between the control panel and the central control electronics.

- Models from the Margherita series report this error by means of a permanently lit "lock" indicator and repeated flashing of the power button of the machine. In this case, the button blinks 12 times in a row, followed by a pause of 15 seconds, and then the blinks are repeated.

- On ARXL, ARSL and ARL series machines this error is displayed by the simultaneous pulsation of the "spin" and "drain" indicators. In some models of these series, all function lamps may come on at the same time.

- Ariston AVSL Model reports this error by flashing the Superwash, Key and / or Lock LEDs and the Delayed Wash Timer at the same time.

- By car Hotpoint-ariston aqualtis this error manifests itself in the simultaneous switching on of the LEDs on the temperature scale corresponding to the 40 ° С and 50 ° С modes.

Most often, this error appears immediately when you turn on the device. Occasionally, it occurs after the start of water collection, but before the tank is completely filled. In such cases, its appearance is often accompanied by unusual loud sounds, which are emitted by the inlet valve of the device during water collection.

Reasons for the appearance

Disruption of communication between the central electronics and the periphery of the control panel can occur for the following reasons:

- accidental shutdown (mainly due to vibration), rupture or damage to the loops connecting these modules;

- problems with controller firmware on one of the boards;

- failure of elements on one of the microcircuits (most often problems arise with capacitors, diodes, relays, semistors and resistors);

- violation of the integrity or functioning of tracks on microcircuits (water ingress, short circuit, mechanical damage, overheating);

- breakdown of the central processor.

The most common reason is the ingress of moisture on the microcircuits, which can lead to both temporary failure of the tracks and elements, and to their irreparable damage. This usually happens when washing heavy and bulky items that cannot be completely wrung out. As a result, water remains in the drum at the end of the wash, which can get inside the machine and flood its boards.

Another common cause of breakdown is voltage surges, which can not only lead to the combustion of individual elements of microcircuits, but also damage the connecting wires.

Finally, sometimes rodents, gnawing the connecting cables, become the reason for the disconnection.

How to fix?

Error F12 is quite serious, and in most cases its elimination will require repair at a certified center. However, there are steps you can take before unplugging your machine and taking it in for repairs.

- Disconnect the device from the network and let it "rest" for several hours. If moisture has become the cause, it is possible that during this time it will dry out and the functionality of the machine will be restored.

- If disabling does not help, you can try restarting the control system. To do this, you need to repeat three times the cycles of turning off the machine, disconnecting the mains wire, connecting it back and turning on the device. The pause between reboot cycles must be at least 7 minutes.

If these 2 methods do not help, and the machine is still under warranty, call the service center representatives right away. Even if the case does not turn out to be guaranteed, any attempts to fix the breakdown on your own can lead to a complete loss of the warranty.

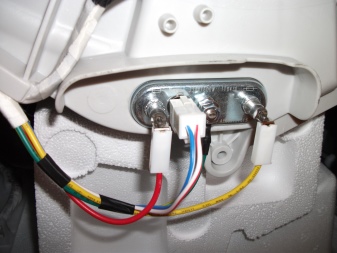

If the warranty period for your device has already expired, then you can first try to fix it yourself. For this you will have to remove the entire rear wall of the machine and carefully examine the central module and control system. First of all, you need to disconnect all the cables connecting them and reconnect them. After that, we put the cover back (this is a prerequisite, violation of which is fraught with an electric shock) and check if the error has been eliminated.

If reconnecting the loops did not help, you need to carefully examine them for mechanical damage or traces of burnt insulation, and also "ring" each wire with a tester. If you find a break, replace the broken wire.

If it turns out that the problem is not in the loops, then you will have to dismantle and inspect the control panel and the control module. It's easier to start with the latter - it's in the lower left corner near the back of your car. Before disconnecting all the wires from it, be sure to take a picture of it in the connected state, so that it is easier to correctly connect all communications back when installing it.

Inspection of the dismantled module must begin with a search for swollen capacitors, broken diodes and burnt resistors. In most cases, damaged parts are black carbon deposits, so it won't be very difficult to find them. Broken parts must be replaced with completely similar ones, preferably from the same manufacturer.

If the entire element base is intact at first glance, we carefully check all the tracks. If you find a burnt or damaged area, you can try to restore contact by re-soldering it after thorough cleaning.

If everything is in order with the control unit, you will have to check the board located on the front panel. It will be more difficult to remove it than the central module. Its inspection should be carried out in the same sequence.

If the damage to the elements and contact tracks could not be found, then most likely you will have to contact a specialist. However, if you have a programmer at home and understand microelectronics, then you can try to reflash the microcontrollers on both boards before that (provided you have a saved factory firmware).

How to repair a Hotpoint-Ariston washing machine, see below.

The comment was sent successfully.