Do-it-yourself Bosch washing machine repair

Bosch washing machines are quite reliable and stable. However, even this solid technique often fails. You can also make repairs with your own hands - if you know how to do it correctly.

The device of Bosch washing machines

According to a number of sources, all Bosch washing machines have 28 body parts. They are always arranged in the same way, and disassembly can be carried out without the use of special tools. The drum pulley is attached to a special bolt. Enhanced protection against leaks is required. And also there are certainly the following elements:

- anti-shake stabilizers;

- overload protection system;

- accurate pollution sensors.

A number of Bosch washing machines suffer from linen hatch problems. The latch may be too tight or stop closing. The range of the German company includes devices with front and front loading methods.

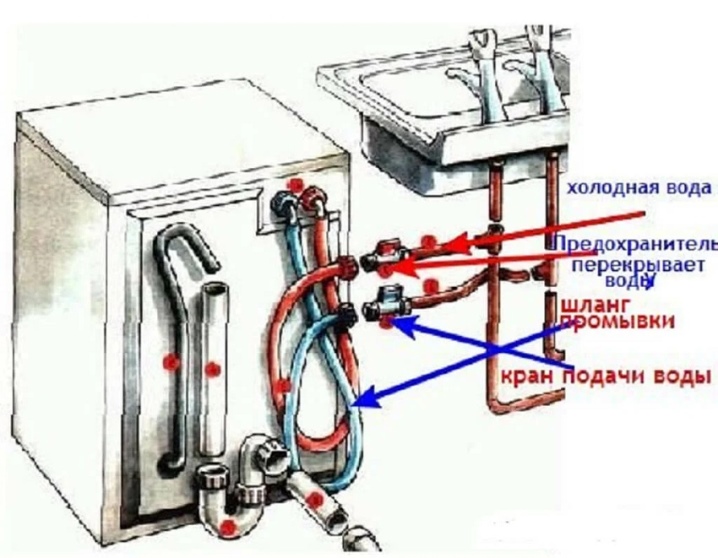

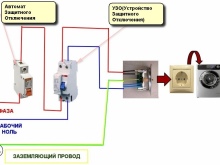

As for the connection, it can be done in various ways. Direct connection is possible for almost any model produced by a German company. But the problem is that the installation of a hose directly into the water supply system is not available everywhere. Often you have to use plumbing "doubles" and even "tees". In systems with old mixers, water is supplied through adapters with a tap installed at the mixer inlet. An extension sleeve is then used to supply hot water. In the second method, the hose is connected through a tee mounted in the shower head line. Sometimes a simple connection to flexible hoses is used.

Old metal pipes allow you to use a variety of self-tapping methods. But polypropylene pipes used after a major overhaul do not provide such an opportunity. You will have to connect to them using a special soldering iron. And almost all people should call a professional plumber. XLPE and metal-plastic are usually connected through special fittings.

Required tools and spare parts

Experienced craftsmen have a certain set of tools for a long time. This composition includes not only officially sold tools, but also self-made devices. For homework with Bosch washing machines, it is imperative to have a pair of screwdrivers, pliers and wrenches of various sections. It is also worth preparing nippers, pliers, a medium-sized hammer, and a metal service hook. It is inappropriate to buy expensive branded sets; it is much more correct to choose equipment for yourself personally. It is also advisable to stock up on a drill, punch and saw for metal.

In addition to tools, you will also need accessories. When problems arise with the door, a hatch handle is often needed, which can fail due to improper use or simply from time to time.

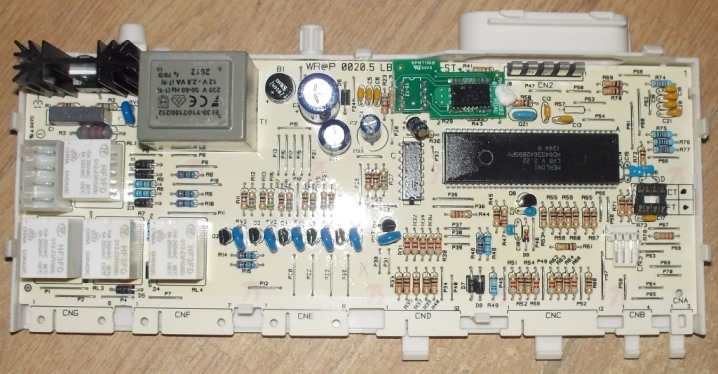

If you already have experience in handling electronics, you can also change more serious components - the main boards and control units. But it is better to entrust the work with them to professionals.

In some cases, a tank spider is used. This part is responsible for maintaining the stability of the device. If the crosspiece is broken, loud noises and rattling sounds inevitably occur.Ignoring the defect is dangerous, since the heating element, the drum, and even the tank body may suffer. In any case, the replacement part must meet the strict requirements of Bosch. Like other components, it is better to purchase it in the company store.

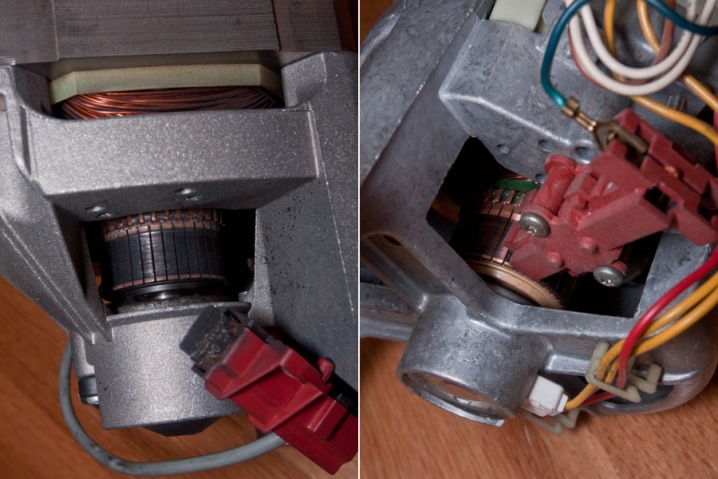

But special attention must be paid to the motor of the washing machine. The German manufacturer always tries to put it at the bottom. This greatly reduces the risk of moisture injury. But it cannot be completely ruled out. The most likely defects are as follows:

- mechanical wear of bearings, rotor, stator, coils, windings;

- ingress of liquid, including condensate;

- rupture of power circuits.

In some cases, the drive belt will come off the motor. It can also wear out or weaken over long periods of time. Belts are usually tried to be replaced unless it is possible to simply put them back in place.

But the engines themselves are most often tried to be repaired. Since this is a really difficult job, it is worth it, and the selection of spare parts, to entrust professionals.

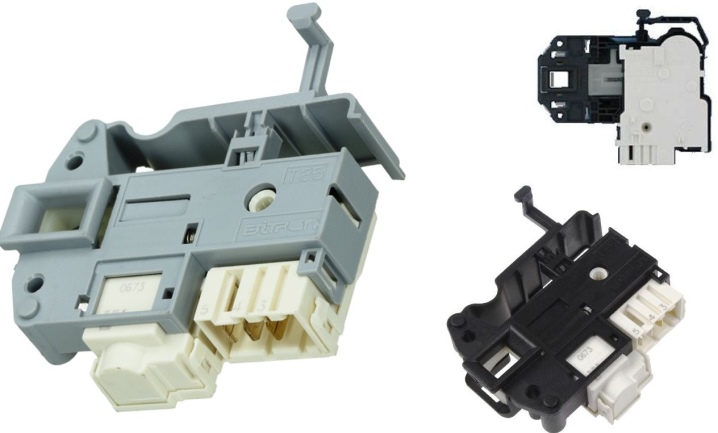

The door lock for Bosch washing machines is, of course, very reliable. But this device can also break. The following elements are used to repair it:

- plates;

- pins;

- contacts responsible for transmitting a signal to the control board;

- bimetallic plate.

Sometimes, however, the hatch cover or the glass that is inserted into it is damaged. These parts can also be replaced with a skillful approach. But periodically it is also necessary to service the branch pipe of the washing machine. The normal circulation of water inside the case depends on the three main pipes. And which of these blocks will fail - it is impossible to predict in advance. It is only known that the drain pipe breaks most often. It is he who meets with all kinds of blockages and foreign objects.

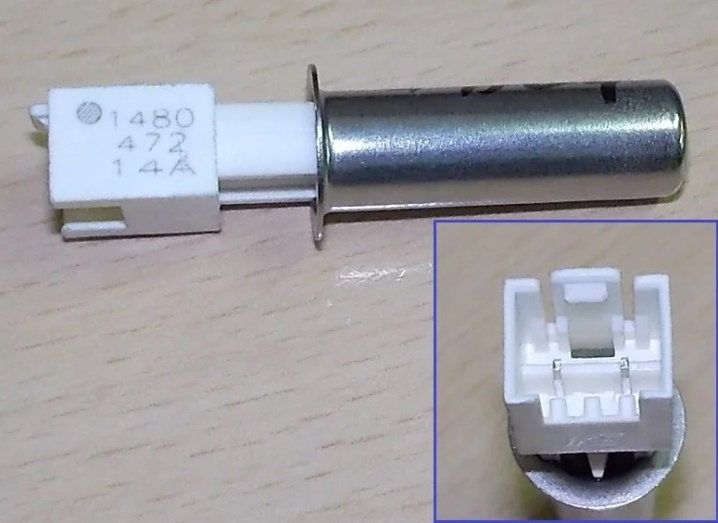

Another node in which problems often arise is the pressure switch of the washing machine. If it fails, the automation cannot determine exactly how much water to pour into the tank, and whether it is necessary at all. In less difficult cases, water is still poured or poured, but less than necessary.

Diagnostics

But just buying a part that is suspected of being broken is not enough. After all in the washing machine everything is interconnected, sometimes they "sin" on one part, but a completely different block is to blame... Therefore, diagnostics must be performed. The first step in verification is to differentiate hydraulic problems from electrical and electronic problems. The exact procedure for starting the diagnostic mode is always given in the operating instructions.

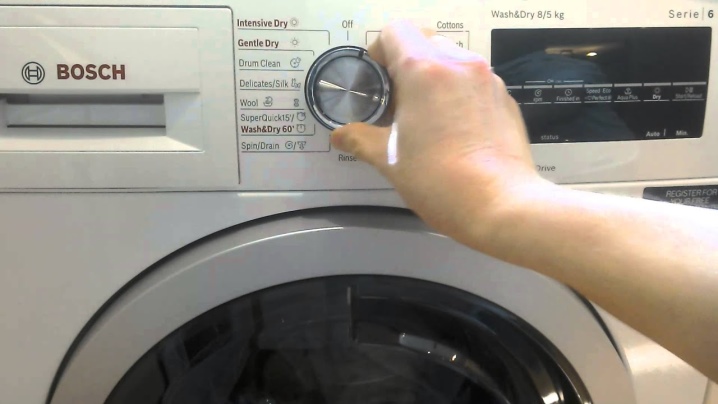

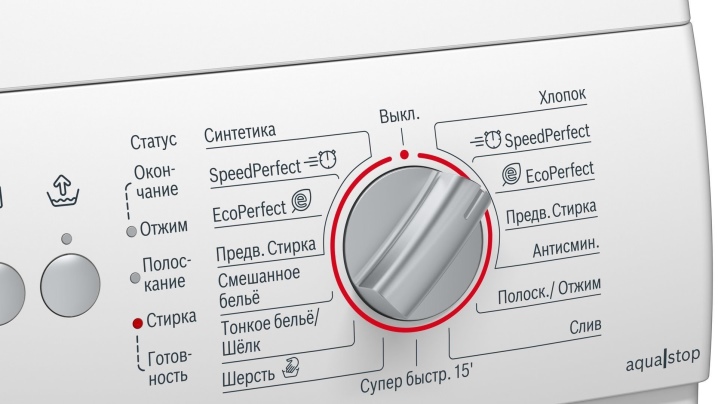

Let's say you have to work with machines of the Max series. Then, to use the diagnostic tools provided by the manufacturer, you will need to do the following:

- close the door;

- move the program pointer to zero position ("off");

- wait at least 3 seconds;

- move the handle to operating position 8 clockwise;

- as soon as the flashing of the start button stops, press the speed control button;

- move the program knob to position 9;

- remove your hand from the spin button;

- consider which malfunction was the last (attention - when it is highlighted, it will be erased from the machine's memory).

Next, the test is set using the program selection knob. The numbers 1 and 2 will not be used. But in position 3, a check of the working motor is set.

With the knob in position 7, you can test the water filling valves for the main and prewash. Separate scanning of these valves is carried out respectively in positions 8 and 9. Number 4 will indicate drain pump testing. In mode 5, the heating element is examined. By setting the program indicator to 6, it will be possible to check the hot water supply valve. Mode 10 will help to assess the adequacy of sound signals. And positions 11 through 15 indicate various automatic tests.

During the diagnostic process, the indicators should be on continuously. If they go out, then this means either a power outage, or an extremely serious failure, which only professionals can definitely handle. Exit the test program by pressing the start button and turning the program knob, then the indicators will flash. Exit from the general diagnostics mode is made by moving the program selection knob to zero.

When testing spinning and draining, the pump should run non-stop. But the rotation of the drum changes. This mode does not allow you to determine the load imbalance. But the limits of this imbalance will be effectively detected. Draining testing implies the following:

- door lock;

- complete removal of water;

- shutdown of the pump;

- unlocking the hatch.

When automatic programs are executed, conditional error codes are displayed.

- F16 signal indicates that the door has not been closed. You will have to restart the program after closing the hatch.

- And here error F17 indicates that water is entering the tank too slowly. The reasons may be clogged pipes and hoses, a closed tap, or a weak head in the system.

- F18 signal speaks of a slow drainage of water. Often such an error occurs due to a breakdown of the drain pump or due to blockage of the pressure switch. Sometimes malfunctions occur in the water level controller.

- Concerning code F19, then it shows the excess of the prescribed time for heating the water. The reasons are varied - this is a breakdown of the heating system itself, and insufficient voltage, and the coating of the heating element with limescale.

- F20 says that there is an unexpected warming up. It is caused by breakdowns of temperature sensors. Problems can also relate to the heating element relay.

- And here F21 - multiple-valued error. It shows the following:

- control failures;

- uneven drive action;

- the inability to spin the drum;

- short circuit;

- problems with the generator;

- failures in the reverse relay.

- F22 code indicates a breakdown of the NTC sensor. Sometimes it suffers from a short circuit. But in other cases, the cause of the problem is a malfunction of the sensor itself or an open circuit. The test will end without heating the water.

- Error code F23 indicates the activation of aquastop, provoked by the accumulation of water in the sump or the breakage of the connecting circuits.

Typical malfunctions and how to fix them

Doesn't spin the drum

This type of malfunction can be associated with a variety of undesirable circumstances. Sometimes you can fix the problem simply by restoring the normal power supply.

It is necessary to check if there is current in the house, if the machine is plugged into the outlet. A more complex and non-obvious source of problems is a malfunction of the wiring in the home electrical network and inside the car.

And also sometimes, if the drum does not rotate, you have to check the following:

- electronic board;

- the inside of the tank (there should be no foreign objects);

- the gap between the tank and the body (from time to time something gets there, sometimes you even have to do a partial disassembly of the machine);

- drum flaps (in vertical systems);

- bearings (they periodically jam).

The door does not close

This problem can befall owners of a wide variety of Bosch washing machines, including the Maxx 5, Classixx 5 and many others. Diagnosing problems in general is pretty straightforward. First you need to understand if the door is physically fixed. If a characteristic click is not heard, then there is simply no contact. In such cases, almost always the problem is associated either with a foreign body that interferes with a tight pressure, or with poor operation of the lock.

The following reasons for this defect are possible:

- deformation of a special guide;

- failure of the blocking device;

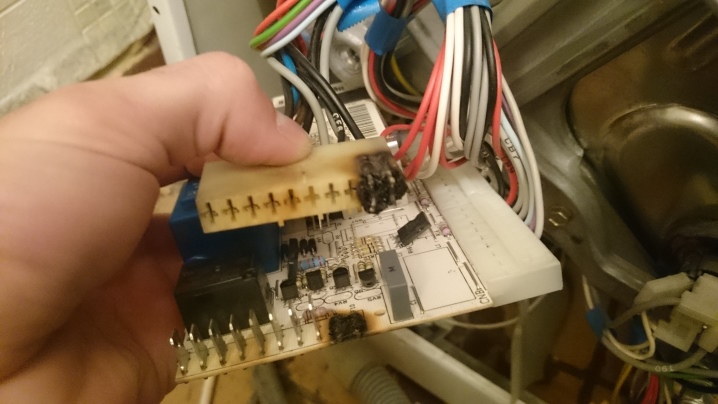

- damage to the control board.

The guides are made of plastic and are relatively thin. Repair of this part is impossible - it only needs to be changed. But it is quite possible to fix the blocking device with your own hands at home.It is carefully examined, if necessary, cleaned of impurities.

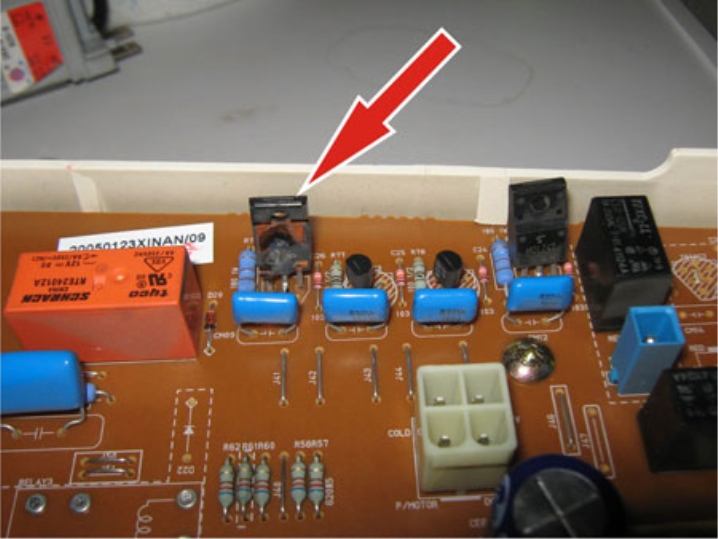

If working with the UBL did not help, you should assume the worst - a breakdown of the control board. The tracks on it often suffer from power surges. For the same reason, software can get confused. The problem module will have to be reprogrammed, repaired or completely replaced, depending on the severity of the defect.

Important! The control board is too complex and serious a device to go in there with a soldering iron in hand. If there is a suspicion of its breakdown, it is still better to use the help of professionals.

Inverter does not work

The inverter-type motor allows you to slightly reduce the noise level and make the machine more comfortable. But this is a very complex device. And again, at home, it is really possible to repair a unit with bearings. The electrical circuit is quite complex, and only experienced specialists can figure out what is wrong with it. Of course, it is quite possible to fix a broken wire on your own - but that's all.

Replacing the drain hose

The drain hose on the Maxx 4, Maxx 7 and any other models can only be changed after removing the front wall and top cover. It is necessary to prepare a "working field" and from the rear wall. The end of the hose is disconnected from the pumping device very carefully, without haste. The clamp is loosened with L-shaped pliers. Then remove the plastic clip located at the exit from the case. Pulling the hose outward, fix the new one in the reverse order.

Water flows from below

In some cases, this problem is due to the fact that the check valve is leaking. It will have to be changed.

In other cases, the pump ring, volute or impeller of the same pump is changed. It is also worth checking the branch pipe - perhaps its rupture will force this part to be changed.

Sometimes you have to perform the following actions:

- change the pump hose;

- replace rusted bearings;

- strengthen the hose connected to the detergent dispenser;

- repair the flow sensor.

Knocks out the machine when turned on

When the protection system is triggered, it should be assumed that the heating system has broken. Microcracks appear on the heating element, through which water gets inside. But if malfunctions occur at the very beginning of the wash, problems with the heating element have nothing to do with it, and you need to deal with the control board. More precisely, with a noise filter installed on it. Problems can also be associated with triacs. The exact answer to what needs to be done will only be given by in-depth diagnostics.

Does not heat water when washing

Contrary to popular belief, the heating element is not always to blame for this. Sometimes you have to repair a broken electrical circuit. In other cases, it is necessary to work with temperature and water sensors. You can also assume a general control system failure or a crashed utility program.

To check the temperature sensors, you will have to partially disassemble the machine.

Does not respond to touch buttons

The most serious reason for such a failure, of course, is the failure of the control automation. But sometimes the problems relate to the buttons themselves or the wiring. And also it is worth checking if the machine is plugged in, and if there is voltage in it. Sometimes actions such as:

- replacement of a faulty or unsuitable extension cord;

- network connection without an extension cord;

- replacement of the noise filter;

- turning off the child protection mode;

- complete replacement of the sensor (if the previous steps did not help).

Other breakdowns

When the machine is noisy, bearings and shock absorbers often need to be replaced. In some cases, the whole point is that the counterweight has been torn out of its place. It is also worth checking if there are any foreign objects in the tank. Sometimes a small speck is enough for a strong roar to be heard.

Very often people are faced with another defect - the machine does not collect water. First of all, you need to check if the water supply is working, if the pressure is too weak.If all this is in order, and the valve at the inlet is open, but there is still no supply, it can be assumed that the pump or the Aqua-Stop complex is clogged. But before you clean them, you should also make sure that the hose is not kinked or pinched by anything. From time to time, even in an advanced Bosch machine, there are problems with the oil seal. In the simplest cases, you can limit yourself to changing the lubricant; in more complex situations, you have to change the whole part.

Sometimes there are complaints that the Bosch machine washes for a long time. In this case, the most trivial check is necessary - perhaps a program that is too long has been mistakenly chosen.

If this is not the case, the first "suspect" is the heating block, or rather the scale on it. This danger is especially great in equipment that has been used for more than 6 years. And you can also assume problems with the thermal sensor, with water drainage. In the latter case, the machine will continue to work until the water is manually drained forcibly.

The fact that the car freezes at the last minute indicates a malfunction in the heating element or pump. The same problems can be expressed in freezing at the very beginning of the wash. But here already a "powerful competitor" appears - failures in electronics. Hanging strictly at the moments of rinsing or spinning say that something has happened to the drain. But the stoppage of work after several drum revolutions is usually associated with engine breakdown.

Helpful repair tips

The most important thing in such a case is to figure out how serious the problem is. Most damaged mechanical parts can be repaired or replaced by hand. But in case of failures in electronics, for which there is a number of confirmations above, you almost always have to contact a professional service. Repairs are seldom required if vibration is severe. You can almost always limit yourself to unloading excess laundry. But if the knocking and vibration go on constantly, we can assume the following:

- breakage of suspension springs;

- breakage of shock absorbers;

- the need to tighten the ballast bolts.

It is strictly forbidden to disassemble, even partially, a machine connected to the network.

If a particular unit does not work, it is advisable to check all the wires connected to it with a multimeter before replacing or repairing it. Crackles and knocks during spinning are almost always indicative of bearing failures. In this case, you need to change them immediately. Postponing this business creates the risk of failure of the shaft and other important, expensive parts.

How to change bearings on a Bosch washing machine, see below.

The comment was sent successfully.