Features of front racks and their assembly

Front racks are useful and functional designs. High-quality copies are convenient to use, and there is nothing prohibitively difficult in assembling and disassembling them. In this article, we will learn about the features of frontal shelving, as well as figure out how to properly assemble them.

What it is?

Currently, modern frontal racks.

These are the most spacious and practical storage systems that are most often found in large warehouses and storage facilities.

On the front racks of different types, there is a large number of products / goods "scattered" in separate cells. The latter are always freely available.

In most cases, frontal racks are located in the dungeons of modern large warehouses and cargo terminals. It is these systems that are especially in demand at enterprises in which there is a huge turnover. Frontal structures are often installed in very large spaces, many of which occupy several football fields.

Modern front-end racks have distinctive characteristics, thanks to which they do not lose their relevance.

- Such designs are quick-detachable. Thanks to this, the territory of the warehouse can be re-planned, if necessary. It will take just a few hours. It will be very quick and easy to add or remove certain storage areas.

- Most modern front shelving units are made of practical and sturdy metal. The structures have such a device, thanks to which it is possible to make changes to their configuration without the use of welding. You won't need a lot of auxiliary tools for this either.

- Installation and removal of the most massive and heavy loads is carried out using a special loader. These manipulations involving such a technique take just a few minutes.

Species overview

Having roughly imagined how modern frontal racks look and how they are used, you can proceed to familiarize yourself with their different subspecies. Each of the types of such structures has its own distinctive characteristics and features of the device, which are best known before dealing with them. Let's take a closer look at the most popular and demanded types of front shelving.

Palette

Modern frontal pallet racks are especially popular today. Such structures are considered one of the strongest. Structures made of high quality and practical materials are capable of withstanding impressive loads without being subjected to deformation or destruction. The largest and heaviest loads are most often placed on pallet racks.

The name of such racks speaks volumes, because they are primarily designed to store items / goods transported on a pallet container.

This is one of the main components and tools designed for the safety of goods in the conditions of large transit terminals.

Small-sized

There are also small-size front-type racks. These are no less popular and functional designs that are also used in the territory of many warehouses. Basically, small-sized structures are used in places for warehouse accumulation of goods by the final recipient. As a rule, we are talking about warehouses of wholesalers, construction and grocery supermarkets, various trading bases and chain stores.

With specially shaped storage areas

A separate category should include front racks, in which separate storage spaces are provided in a special shape... We are talking about structures where there are dedicated zones that are designed to accommodate, for example, wheels, barrels, various containers and tanks, cylinders. For such objects, ordinary flat shelves and standard load-bearing beams are not suitable, therefore, special storage areas are being developed.

Characteristics of a typical rack

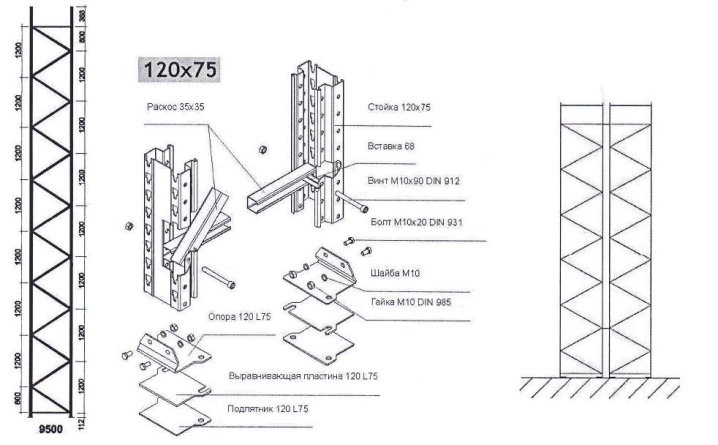

One conventional front section of the design under consideration is usually made for a load weighing no more than 25 kg. This is not the smallest figure, especially considering the fact that the width is only 5 m. The lower support part of the frame base is screwed directly to the concrete floor by means of anchors. Simply put, it is possible to unload the contents of one truck per section.

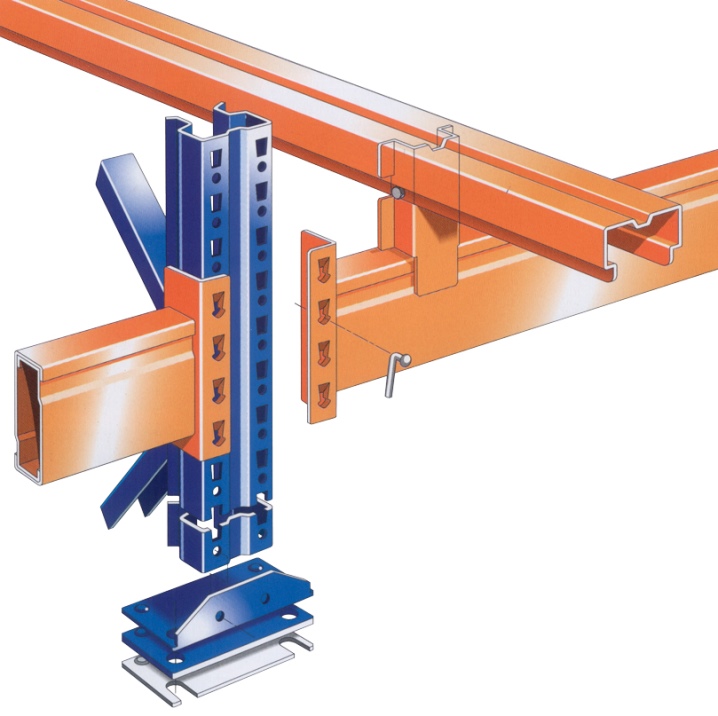

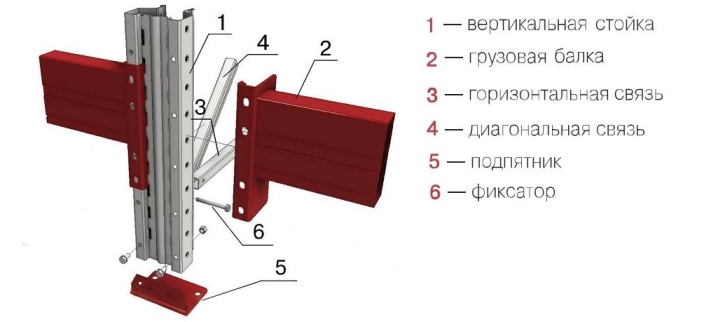

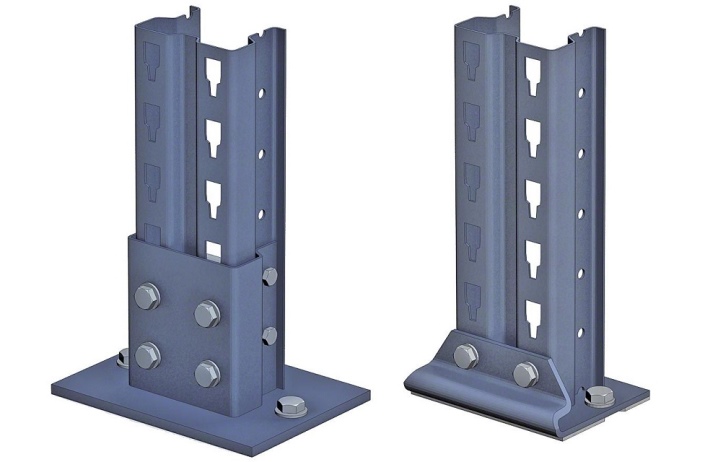

In order for the frame base of the front rack to be strong and reliable enough, vertical racks are made according to a special profile. On the side surface with a pitch of 25 mm, perforation is specially made, due to which the height of fixation of the crossbars can be adjusted at the right time.

Based on the nature of the load placed on the structure, shelf models of different type and structure can be installed on the crossbar transverse parts, namely:

- mesh - ideal for groupage cargo of small dimensions, as well as for goods that differ in non-standard configuration;

- smooth shelves made of metal - designed for placing sheet cargo on them;

- fireproof and pallet floors.

To avoid unnecessary confusion during the assembly of the structure, each of the elements is painted in a specific color. For example, crossbars can be yellow, vertical posts blue, and so on.

Thanks to such markings, operators of loaders and cranes are more accurately oriented in space when placing or picking up certain goods in the warehouse.

Selection Tips

Let's figure out what to look for when choosing the optimal design for front shelving.

- First of all it is necessary to decide for what exactly and for what conditions such a structure is chosen, after all, the same storage facilities will not be suitable for different goods and different areas.

- You should start from the square of the territory on which the front rack will be mounted. Its size must correspond to the dimensions of the warehouse / warehouse.

- The device of the rack itself must correspond to the loads and goods that will be placed on it.... Above, we have already talked about different types of racks - pallet, small-sized and structures with dedicated storage places. It is necessary to choose a modification that is most appropriate and convenient in specific conditions.

- The front rack must be made exclusively of sturdy and reliable materials. The most durable and practical pieces are made of metal. The material must be free of rust, bent parts and other possible damage. A durable and sturdy structure that can withstand heavy loads will not work from low-quality metal.

- It is necessary to decide on the design of the traverse... It must be able to seamlessly support the weight of a particular cell, together with a pallet, drawer and shelves, based on the specific type of the rack itself.

- Today, front racks of various types are produced by many large manufacturers.... It is recommended to choose designs made by conscientious companies that give a guarantee for their products. Excessive savings in this matter can lead to very bad consequences.

Mounting

Installation of a front rack consists of several stages. Let's consider each of them in detail.

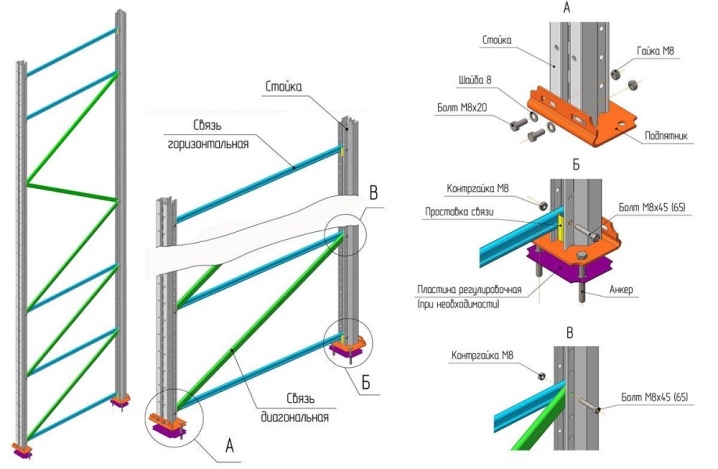

- The first step is to lay out all the racks and diagonal parts of the future design. This should be done in accordance with the assembly scheme.

- You also need to prepare all bolts and cages.

- Next, frame parts are assembled using special keys (meaning wrenches).

- Now it is necessary to unfold the frame in accordance with the scheme of the future structure, parallel to the direction of the row between the heels, approximately equal to the parameter of the length of the beam. Simply put, the top half of the side post should be stacked on the bottom half of the side post, which is "next door". Frames must be correctly positioned relative to each other.

- Now you need to lay out the beams in the immediate vicinity of the side posts. This should be done in the gap between the heels of adjacent side racks in the amount required for a specific section of the front rack (usually at least 2).

- Next, you need to vertically raise the first side stand piece. This is done manually. In this case, it will be necessary to carefully support the lower half of the support. This will require the efforts of about 3-4 people. It is necessary to hold the specified part in an upright position.

- In exactly the same way, it will be necessary to raise the second side stand vertically, and then continue to hold it in this position.

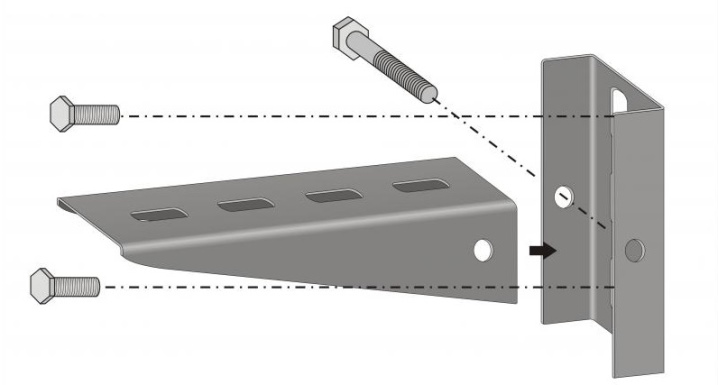

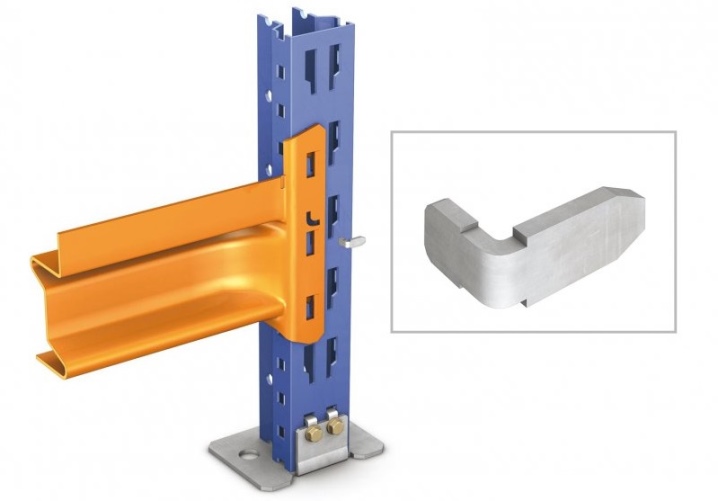

- The next step is to install the beam. This will need to be done using the bracket connectors directly into the perforated hole on the side post and at a certain, desired height. This must also be done in accordance with the design diagram.

- After that, you will need to install a special fixing part. It is she who will be needed so that the connectors cannot come out of the holes on the perforated base. It is very important.

- Likewise, a second longitudinally directed beam would have to be placed directly opposite. A structure consisting of two frames and two beams should eventually receive initial stability indicators. This will be a kind of base for joining all subsequent elements of the front-type structure.

- After completing the assembly of absolutely all rows of the front rack, it is very important to check the immediate distance of the passages. You will need to level the rows and firmly attach the support bases to the floor in the room where the installation work is being carried out.

As you can see, assembly of the front rack does not provide for very complicated and intricate manipulations.

The main thing is to act in stages, strictly according to the scheme and try not to confuse the details of the design. If everything is done correctly, the rack will turn out to be strong and withstand heavy loads.

Helpful hints and tips

If you need to select and independently assemble the reviewed shelving structure, then you should listen to some useful tips and tricks on this topic.

- When assembling the front rack it is important to properly fasten the parts to each other. In this case, it is forbidden to use a metal hammer (sledgehammer), as well as to inflict strong blows, which can lead to deformation and damage to paint and varnish coatings on metal surfaces.

- By drilling the necessary holes for anchors, it is necessary to preliminarily coordinate the areas for drilling with the customer or his representative for hidden electrical wiring and other important communications. It is recommended to drill using special rubber gloves, as well as to avoid contact of the metal structure with other members of the team and unauthorized people.

- There are cases when it is required to place not one, but several loads at once in one section of the front rack. If this is a classical design, then it will be impossible to do this. For such storage, racks with double shelves are ideal. In such structures, the width of the tier is made wider.

- If the warehouse contains not concrete, but ordinary asphalt floors, then special plates will first need to be installed under the racks, so that the floors under the structure will not undergo deformation. The load from the racks will be evenly distributed.

- There are such modifications of front racks, which provide spacious decks... They are made from wood or practical metal. Such structures are ideal for situations where the cargo can be placed not only on the surface of pallets and pallets, but also in bulk.

- To enable the operator of the automatic forklift to work in a more comfortable environment, and the frame of the front rack was well protected from possible damage (collisions, impacts by wheels), it is advisable to install special bumpers or bumpers in its lower parts. This is a very practical solution if you want to extend the shelf life and reliability of your rack.

- If the front shelf rack is made with a narrow aisle, then the density of storage during its operation will also increase significantly. Because of this, there will be more racks and access to the cargo will be difficult. Special equipment for narrow aisles is very expensive - this must be taken into account... If structures with double shelves are used, then access to the back rows will also be more difficult. In this case, you will have to remove the first row.

In this video, you will learn what front shelving is and what their advantages are.

The comment was sent successfully.