Overview of gravity shelving

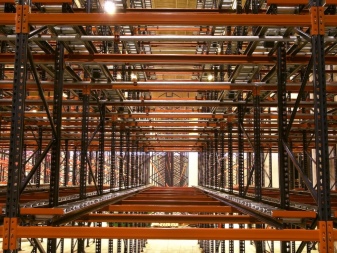

Today's logistics system, as well as the profits of companies, to a large extent depend on the extent to which warehouse premises are thoroughly and efficiently organized, what technological equipment is used, and what is its functional potential. In the article we will consider the latest innovative developments - gravitational racks, which in terms of their performance are identified with mobile systems.

Peculiarities

Gravity racks are roller guides mounted on specialized frames at a specific angle, which form roller shelves (sliding shelves).

The shelves can be divided into "channels" corresponding in width to the dimensions of the cargo.

The load placed from the raised edge of the shelf under the influence of gravity moves independently along the rollers along the channel and stops at the stop.

In addition to the many similarities with the printed versions, these racks have many differences. If in traditional storage systems the guides are located horizontally, then in gravitational storage systems the slope can reach 5%. Their structure assumes the presence of specialized pallets, which are installed by means of stackers. Guides from roller systems allow pallets to move downward under the influence of gravity.

The movement of pallets is carried out along a channel, the length of which can vary and reach 30 meters.

Pros and cons of gravity systems

It should be noted right away that gravity racks have a large number of advantages, although some disadvantages of these systems are also inherent. Consider the positive qualities of these shelving:

-

the ability to reduce the number of trucks and staff in warehouses;

-

increasing the speed of processing goods and the capacity of the warehouse;

-

compliance with the terms of product sales due to the FIFO principle (first-in-first-out);

-

the goods on the shelves are perfectly visible from various angles;

-

block storage of goods in gravity racks makes it possible to radically increase the storage volume in comparison with shelf racks, which provides an increase in area of up to 30%;

-

it is possible to create an automated control system (ACS) and search for goods, as well as control over quickly perishable products;

-

Regardless of the higher cost, in comparison with shelving racks, gravitational systems pay off in a total of 1.5-2 years, and the percentage of accidents when using them is much lower.

If we talk about the shortcomings of this type of warehouse equipment, then we can pay attention to two especially significant:

-

special requirements for the shape of pallets and boxes;

-

the need to resort to the help of specialists to accurately calculate the system, taking into account the size of the warehouse and the requirements for the functionality of the product.

However, due to the fact that the above disadvantages are very relative, more and more consumers opt for the installation of such racks.

Specifications

Technological equipment in logistics is constantly improving, and gravitational systems are a clear example of this. The shelves are capable of withstanding loads of up to 200 kg / sq. m. Warehousing and storage of goods can be carried out in any container, boxes and pallets of various sizes and shapes that meet the technical characteristics of the racks.

Gravity structures can be used in rooms with temperatures from + 40 ° C to –28 ° C, in dry and damp warehouses.

When installing gravity systems, the number of passages between them is reduced. The rollers are made of high quality steel, which guarantees their use up to 50 thousand cycles, and the load size up to 240 kilograms.

The roller track is capable of reaching up to 3.6 m in width and up to 5.5 m in length. In the unloading area, the slope angle of the track can increase up to 15 degrees.

Up to 90 pallets can be loaded and unloaded in one hour.

Description of species

Depending on the place of use, the racks are divided into two broad categories.

Racks for boxes

Gravity box racks are used when goods are stored in plastic containers. In such a situation, the cargo from the loading area is sent to the shelves, where, under the influence of gravity, it gradually moves to the place of unloading. Such shelves can also be placed on ordinary racks, which guarantees dynamic storage of goods.

At the same time, combinations are possible here: at the top there are loads on pallets, and at the bottom - gravitational racks.

Pallet racks

Cylindrical rollers installed in the channel of the gravity rack are responsible for the longitudinal movement of the load. There are also brake rollers that predetermine the travel speed. When the first pallet reaches the stop, the movement is automatically interrupted.

And there is also a separation system to ensure that the last pallets do not overlap the first.

Appointment

Gravity racks are mainly used in areas where goods are accumulated, in so-called buffer stocks, where goods are commissioned.

Practicing gravity structures and in the areas of the expedition in the warehouse.

They are widely used in warehouses where goods are stored according to the principles of first-in-first-out (FIFO), in warehouses that act as refrigerators.

Gravitational systems are used in warehouses for food products, as well as manufactured goods. These racks are also used in storage areas where the accumulation and assembly of goods and goods is carried out, as well as in the cosmetic, food, chemical and pharmaceutical industries for faster use of those goods where the shelf life has limitations.

Gravity pallet racks are also installed:

-

in warehouses for storing electronic and car parts, due to their compactness and the ability to organize an automatic control system - by means of computers, when the names of goods are in the tens of thousands;

-

in the areas of picking goods according to different characteristics and other links in the logistics chain.

With regard to the technique that can be used to service gravitational structures, it can be either an ordinary loader or a channel. The main condition is that their lifting height and lifting capacity meet the requirements.

The volume of cargo that gravitational systems can accommodate is quite impressive in warehouses with limited space - racks take up to 70% of the total area of the room. Due to this feature, it is easy to delimit the loading area from the unloading area, which will greatly simplify the work of warehouse employees and technicians.

The comment was sent successfully.