How to cut glass without glass cutter?

Cutting glass at home has not previously provided for the absence of a glass cutter. Even with careful actions, not exactly cut, but broken pieces were formed, whose edge remotely resembled a curved line with slight bends in both directions. It is still possible to cut glass without a glass cutter.

What can be used

Cutting glass without a glass cutter is not the easiest task a beginner poses before himself. The difference in methods is in the type of impact on the material itself. Heating, for example, is possible only on a certain area of a piece of glass. The use of the increased force allows the force applied to the glass to be concentrated on one line. In the factory, glass is cut using a high pressure fluid.

When cutting glass by means of directional heating, in the simple case, twine, flammable liquid and matches. The rope or thread is pulled and tied along the cut line, a combustible or combustible lubricant is applied to the harness. The strapping is set on fire - creating a high temperature, with a sharp drop, it will cause the sheet to crack. The location of the break approximately follows the contour of the twine or thread. When such a "handicraft" method turns out to be too dangerous (you can ignore objects around or yourself), use a burning tool or a soldering iron with a power of at least 60 watts. The soldering iron can be replaced with a gas torch with a thin nozzle, which gives out a tongue of flame no thicker than the fire from a lighter.

Impact with a concrete drill, file, diamond disc, scissors or nails makes it possible to cut the sheet when there is no source of fire or objects that can be heated nearby

Rivalry with factory methods that involve a diamond knife or cutter may not work perfectly. The cutting line is not always straightforward, as under the ruler - it will lead to the side.

Files

A chisel file is not suitable for obtaining a relatively straight line. It has rounded corners. Use a square or box-shaped tool. The method is similar to that in which an ordinary glass cutter is used. To obtain an even furrow, press the file handle harder than during normal use. Make sure there is a clear groove on the glass sheet. Then the glass breaks flat against the corner of the table. A file with a triangular section is ideal.

Grinders

You will need a cutting disc for metal - with a thickness of at least 0.1 mm... A thick disc will not allow you to cut the glass sheet neatly: the area of contact between the disc and the surface increases, and the line looks blurred. The disadvantage of this method is that a not too powerful and large electric drive is required, otherwise it will become much more difficult to hold it.

Ideally, the use of not a grinder, but small sawing machine made on the basis of a drill... It must not be held suspended, but secured by means of guide rails with adjustable height. This will make it possible to achieve uniform action of the disc on the cut surface along the entire length. One sharp and inaccurate movement - and the glass will not be placed under the line of the desired trajectory, but will fly into fragments. Here, not a through-cut is needed, but only immersion to a shallow depth of the layer, not exceeding one tenth of its thickness.Sawing through the glass sheet, the master runs the risk of getting many small cracks and this spoil the appearance of the cut rectangular piece or break it directly during marking.

Scissors

Cutting glass with scissors in water is good for creating a curly rather than a straight cut line. Thicker than 4 mm glass is difficult to cut with scissors in water. In principle, this method is suitable for cutting 2.5-3.5 mm window glass. Water is needed to prevent the scattering of fragments and getting them into the eyes, nose or ears of the master. Glass is cut in a bowl or barrel of water. The capacity allows you to accommodate the entire processed piece of glass. The principle underlying the method is directed cleavage of the material. Water will not allow the glass to crack completely - its resistance softens jerks, jabbing movements that break the same glass without it.

Soldering irons

The sharp heating of untempered glass causes the latter to crack... The cutting line from the spot heating will not become ideal, as after passing the glass cutter in the right place. She will deviate slightly. But it will be possible to insert the resulting piece into the wooden window frame without spoiling the look of the window "eye". To obtain a curly line (for example, when an original curly frame is made along the resulting line, repeating its contour), a soldering iron (or a wood burning machine) is perfect.

In this case, you need to follow a certain sequence of actions..

- A piece of glass is drawn with a construction felt-tip pen or marker.

- At the beginning and at the end of the intended cutting line - on the edges - the glass is carefully cut with a file. The notches will help to more accurately define the direction of the crack formed from the heat.

- Having stepped back from the edge of the glass by 2 mm, the master applies a heated soldering iron to the edge of the glass. The beginning of the process will be the formation of a small crack - from a sharp temperature drop.

- Repeating the indentation from the heating point, the soldering iron is applied to the glass again. The crack will go further - in the direction given by the master. The soldering iron is brought to the end of the cutting line. To speed up cutting, a wet rag is applied to the glass - so that it cools faster, and the temperature drop is limiting.

After thermal cleavage is completed, the desired piece is easily peeled off. To obtain a straight line, use a metal ruler or a piece of metal profile.

Victory drills

A concrete drill with a victorious tip, just bought and never used, is a slightly worse way than diamond sputtering to cut glass. But with a sharp drill, the bottom of the cans was drilled earlier: with careful actions, the container did not crack.

The only difference is that the glass is not drilled - a groove is scratched in it in the right place. Then it breaks - as if it had been marked with a simple diamond cutter. To draw an even furrow, use a ruler and a marker: the leading strokes are outlined first, the second allows you to keep the drill or drill on the cutting line. Since the glass has a perfectly smooth, transparent and glossy surface, apply slightly more force than a standard diamond cutter.

A blunt, used drill will not work: it is extremely difficult for them to scratch the cutting line, and the excessive effort of the master will simply split the entire sheet. The main thing is that the tip of the straight edge or the tip of the victorious tip, and not the side edges, draw a line.

High-speed steel will also scratch the glass - but after the first centimeters of the line drawn, it will immediately become dull, so it needs to be sharpened. The disadvantage of this method is obvious.

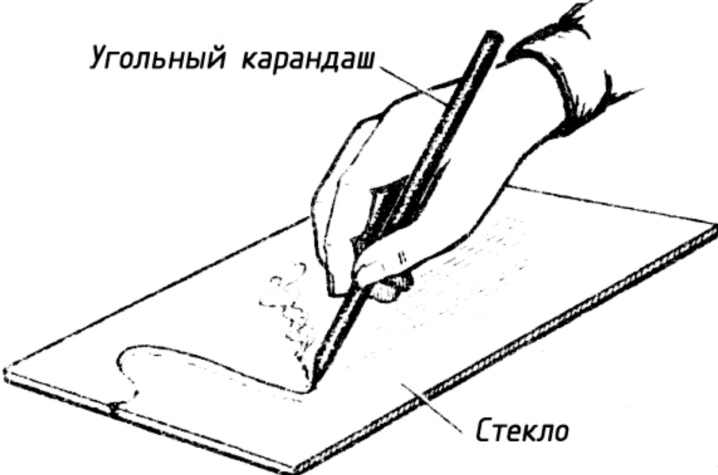

Charcoal pencils

Before drawing a cutting line, such a pencil is made independently as follows. Charcoal is ground into powder, gum arabic is added and charcoal sticks are formed from the resulting paste, which must be thoroughly dried.

Having marked the prepared sheet with a marker, making notches at the beginning and end of the cutting line with a file, the pencil is set on fire from one of the ends. A crack will appear from the temperature drop. It is very easy to separate the desired piece along this crack.

An alternative to pencils is a string or even a thin line made of flammable, flammable material.... Thus, large and long pieces of flat glass can be cut with diesel or turpentine applied in a straight line, strips of burning rubber or even dripping polyethylene when burning. Possibilities to heat the glass pointwise along the line are limited only by the imagination of the performer - within the framework of the thermal method.

The thermal method will not work with simple tempered and quartz glass - it can withstand sudden changes in temperature from zero to hundreds of degrees.

How to cut glass correctly

The glass is washed, dried and degreased, placed on a perfectly flat table, covered with cloth or linoleum. The material under the glass should be thick and dense. Perfectly clean glass will exclude the possibility of the cutting tool slipping to the side. To get an uneven line, use a variety of templates or a self-made blank with a face of the desired curvature.

Do not work without safety glasses and gloves... Hands and eyes, even when cut in water, must be protected. With unsuccessful attempts to even break, a second cut line is drawn - 2 cm from the first. Instead of gloves made of thick and coarse fabric, do not use rubber or polyethylene - both rubber and thin plastic are easy to cut with sharp edges of glass.

How to cut a glass bottle

Cutting a bottle without the help of a machine at home is much more difficult than cutting a window pane. Use a lit string or twine... The glass of the bottle is warmed up at the place of burning of the twine, the cut vessel is dipped into water - the bottle glass cracks from a sharp temperature drop.

Recommendations

Do not try to cut tempered glass... After being tempered, such glass changes its internal structure: if you try to cut it, drill a hole in it, it crumbles into glass crumbs - small cubes with blunt edges. A part or object made of ordinary glass that has been completely processed (drilling, cutting) is hardened, and the same object is not subject to further processing.

Distribute the cutting force evenly: light pressure will not work and the glass will not break along the line. Too strong - will lead to cracking, irreversible damage to the cut sheet.

Correctly following the above recommendations, the home craftsman will cut and process any glass blank, even without a machine, glass cutter and other tools and devices usually used in a production workshop or garage.

In the next video, you will learn how to cut glass without a glass cutter.

The comment was sent successfully.