All about fiberglass

The building materials market offers a wide range of products that are in great demand, except for fiberglass. It is used in a wide variety of industries for numerous reasons. The material has its own special properties that distinguish it from the rest and give it many advantages.

What it is?

Fiberglass belongs to the category of modern composite materials, designed to improve the basic operational characteristics of structures and various products for the creation of which they are used. The mechanical properties of the product depend on the production technology, which is different. Products can be divided according to the arrangement of fibers - unidirectional and cross orientation.

Features of production

The production of material for the further production of certain products occurs in different ways. The characteristics are influenced by the composition and equipment used at the plant. The main component is fiberglass reinforcing material, which is mixed with synthetic binders... Thus, it is distinguished not only by strength, but also by rigidity. The task of the binders is to impart solidity to the material, they distribute the forces between the fibers evenly, and at the same time protect the fibers from the effects of chemicals, atmospheric influences and other factors.

Due to the presence of this component, fiberglass can be formed into products of any shape and size, which is why the material has become so popular in various industries.

Regarding the reinforcement of the matrix, the product is endowed with a property that is not available for traditional plastics. Fiberglass is much more resistant to abrasion and wear, and can also withstand shock, vibration and mechanical damage. Experts gave it the name "light metal", and this is justified. The material has low density and thermal conductivity, it is not afraid of high humidity. Fiberglass has a number of other valuable properties that are acquired due to the peculiarities of production. Cutting of material for the further manufacture of certain products is carried out with special machines.

Properties and characteristics

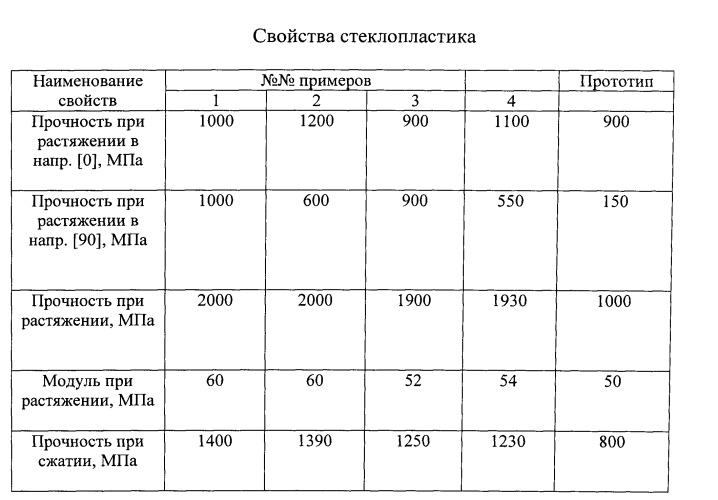

The main advantages of the material include the following. This product is created in accordance with GOST. Fiberglass is universal, since structures made of it are used not only inside, but also outside. Its increased resistance to moisture and precipitation, as well as exposure to direct sunlight has made it so popular. The temperature range is from -50 to +100 degrees Celsius, which is surprising. As for the density of products, the indicator varies between 1800-2000 kg / m3. The modulus of elasticity for fiberglass is in the range of 3500-12000 Pa, most often about 4000 Pa. The specific gravity is from 0.4 to 1.8 g / cm3, so the material is convenient to use in the manufacture of vehicles.

Durability has become one of the determining factors in the growing popularity of fiberglass. Products made from it can last for several decades, while the properties are perfectly preserved, and this is important. When compared with metal or wood, a huge plus is the absence of corrosive destruction and resistance to fungus and bacteria.Strength plays an important role, especially when fiberglass is used in building structures, in terms of its properties in this category it can be compared with steel, the advantage is its low weight, so many manufacturers choose the first option to create equipment and complex structures.

It should be noted the dielectric properties that appear during the use of direct and alternating current. Thermal insulation characteristics are not devoid of advantages, therefore, fiberglass is sometimes used to create sandwich structures together with foam or other porous material.

Views

The types of fiberglass are distinguished by the method of production, each has its own distinctive characteristics and features that are worth familiarizing with.

Contact molded

The technology consists in the impregnation of fiberglass with polymers. For this, hand tools are used in the form of brushes and rollers. As a result, glass mats are made, which are subsequently laid out in shapes, where they are further processed. Rollers roll the contents in to prevent the creation of air bubbles, at the final stage, the product is deburred and, if necessary, holes and grooves are made for further use in a particular industry. In the course of work, various types of resins are used that are combined with fiberglass.

The main advantages of the method include practicality, simplicity, a large selection of components, and affordability. At the same time, it is almost impossible to establish wide performance with such technology.

Also, many people use vacuum to infuse fiberglass products. Specialists use a sealed film that adheres to the matrix, creating a working cavity with a reinforcing material. The binder is pulled inward, impregnated with the last component. As a result, the process becomes partly mechanized and the quality of workmanship is improved.

Produced by winding technology

This method is used by the production of pipes and containers, in which there must be empty space. The bottom line is in passing glass fibers through a bath with a binder, which are stretched by means of rollers. The latter also have the function of removing excess resin. During winding, there are no restrictions on the binding components. It is a fast and efficient method that allows you to adjust the proportions of polymers and glass fibers. Fiberglass gets improved properties, while the equipment for its production is not cheap. For this technology, dies are used, which are installed on a pultruded line. They are strong forms through which the threads are pulled.

Roll

Such fiberglass is flexible and belongs to the category of sheet material. The main advantages of the product are resistance to high humidity and sudden temperature changes, plasticity, lightness, low thermal conductivity and safety. Such material is offered at an affordable price, therefore it is in great demand in the construction industry.

Leafy

Fiberglass sheets are made on a conveyor line using chopped glass yarn with binders that can be based on various resins. This material is divided into several varieties, it is transparent, therefore ideal for greenhouses and other structures where natural light is required. Tinted also allows light to pass through, opaque is available in a wide range of colors.

The main advantages of fiberglass sheet include ease of installation due to low specific weight, corrosion resistance, environmental friendliness, strength to decomposition and stress, ability to scatter light.

Profiles

Products in this form are made by pulling the roving, which is impregnated with polyester binders. Such profiles are convenient and practical to use as structural elements, so they often replace sheet blanks in the production of various parts. This reduces the cost of machining by mechanical means. The profiles are offered in the form of angles, bars and rods. Structural material is used for the manufacture of parts, fittings and various structures, not only outside, but also in interior design.

Manufacturers overview

On the territory of Russia, a wide selection of enterprises is offered that are engaged in the production of fiberglass products. Their products are in great demand, so you should get acquainted with the leading manufacturers who have managed to prove themselves from the best side. Smart Consult company manufactures structural elements used in the construction industry. Leading enterprises use its services. If we talk about the production of fiberglass pipes, there are only a few companies in the country that work in this direction. We are talking about LLC New Pipe Technologies, which is a leader in its field. More than 60% of the products of this manufacturer are on the domestic market, which speaks volumes.

The second largest producer of polyester pipes is "PC" Steklokompozit ", the company continues to actively develop, so the indicators increase annually. The products are often used in the transport industry. Eterus-Techno company specializes in the production of sheet material, which is used in the automotive industry, at the same time the company deals with profiled fiberglass sheet. Excellent performance demonstrates enterprise "Triton", which is the largest manufacturer of acrylic bathtubs not only in Russia, but also in Europe. The factories produce fiberglass, which later becomes a reinforcing layer.

Applications

Since fiberglass is a composite material that combines not only excellent quality, but also an affordable cost, the demand for its popularity continues to grow every year. This material can be painted, applied to various coatings and mechanically processed. Due to the rich list of technical characteristics, the product is used in various industries. In shipbuilding and the production of tank structures, fiberglass is not complete.

It is worth noting that it was this industry that influenced the development of material manufacturing on such a large scale. A large number of small-tonnage hulls in different parts of the world are produced from this material, we are talking about rowing and motor boats, lifeboats, racing yachts and even cruisers, boats, scooters and other water transport.

In addition to the frames, the material is used to create structures for cabins and decks, make wings and navigating bridges, as well as engines and hatch covers. Another industry that does not do without fiberglass is the construction of swimming pools and beautiful garden fountains, artificial ponds.

The automotive industry makes composite body parts and bumpers. Fiberglass elements can be found in the interior of the cabin. But racing cars are completely made of this composite, since in the event of impacts, the shape can be quickly restored, and besides, corrosion is not terrible.

The production of pipelines is not complete without composite components, therefore, fiberglass is actively used in the manufacture of storm collectors. Sewer treatment systems are made of plastic, this includes filters, septic tanks, sedimentation tanks. They are easy to care for, no permanent repairs are required, so the demand is obvious.

Most of all, fiberglass is in demand in the construction industry, because it is used for both external and internal work. It can be an excellent replacement for metal and stone structures, because the strength is at a height. For example, fiberglass reinforcement is often used when pouring the foundation of a low-rise building.

As for tall houses, elements of facades are created from composite material, stucco moldings and beautiful decorative decorations that perfectly complement the overall picture are made.

Wall panels, roofing, facade decor, partitions - all this can be made of fiberglass, which has amazing performance properties and can remain unchanged for many years. Honeycomb panels are often coated with this material to improve sound insulation performance. Exterior and interior wall cladding made of sheet metal looks beautiful and aesthetically pleasing, and there is a wide variety of shades on the market. Many experts consider this product to be an excellent roofing material.

Liquid fiberglass is in demand during renovations, it serves as a reliable reinforcement for building structures such as thermal insulation, roofing, pipes, etc. The material is perfectly combined with porous components. As for interior design, the market offers a wide selection of composite products - dishes, various statues, decorative elements, even furniture.

As mentioned above, in the production of containers of various shapes and sizes, enterprises often use fiberglass. Summing up, we can say with confidence that fiberglass has become one of the most popular types of composite materials, which has captured the market in various industries due to the operational properties with which it is endowed.

The comment was sent successfully.